Okufaneleivalvu yokulinganisaUkukhetha kuqinisekisa ukuphepha kwesistimu okubalulekile. Kuvimbela ukugeleza komthwalo futhi kugcina ukulawula. Ivalvu efanele yokulinganisa ithuthukisa ukuzinza kokusebenza, ihlinzeka ngokunyakaza okubushelelezi. Lokhu kukhetha kuxhumanisa ngqo nohlelo lonkei-hydraulicukusebenza kahle kohlelo.Hanshanginikeza izingxenye ezithembekile.

Izinto Ezibalulekile Okufanele Uzicabangele

- Amavalvu okulinganisela abalulekile ekuphepheni. Avimba imithwalo esindayo ukuthi iwe ngokushesha. Aphinde agcine imithwalo izinzile.

- Ukukhetha ivalvu efanele kubalulekile. Qondanisa amandla ayo nomthwalo wakho. Futhi, khetha isilinganiso esifanele somshayeli wokuhamba okuzinzile noma okubushelelezi.

- Hlola futhi unakekele ama-valve akho njalo. Bheka ukuvuza noma imisindo engavamile. Lokhu kusiza i-valve yakhouhlelo lwe-hydraulicisebenza kahle futhi ihlala isikhathi eside.

Ukuqonda i-Counterbalance Valve

Iyini i-Counterbalance Valve?

A i-valve yokulinganisa iyinto ebalulekileezinhlelweni ze-hydraulic. Isebenza njengedivayisi yokuphepha. Le valve igcina ukulawula i-hydraulic actuator, ikakhulukazi uma isekela umthwalo. Ivimbela ukunyakaza okungalawuleki. Ivalvu iqinisekisa ukuthi umthwalo uhlala uzinzile.

Imisebenzi Eyinhloko Yevalvu Yokuphikisana

Le valve yenza imisebenzi eminingana ebalulekile. Ibamba umthwalo endaweni yawo. Lokhu kuvimbela umthwalo ukuthi ungakhukhuleki noma uwe. Ivalvu nayoilawula ijubane lomthwalo owehlayo. Kudala ingcindezi yangemuva, elawula ukugeleza kokuphuma kwe-actuator. Ngaphezu kwalokho, kuvimbela i-cavitation ku-hydraulic cylinder. I-cavitation ingalimaza uhlelo. I-valve yokulinganisa iqinisekisa ukunyakaza okubushelelezi nokulawulwayo.

Indlela Ama-Valve Okulinganisela Avimbela Ngayo Ukubaleka Komthwalo

Ukubaleka komthwalo kwenzeka lapho umthwalo osindayo uhamba ngokungalawuleki ngenxa yamandla adonsela phansi. Ivalvu yokulinganisa ivimbela lesi simo esiyingozi. Idinga ingcindezi yomshayeli ukuze ivuleke. Lo mfutho womshayeli uvela ohlangothini lokungena lwe-actuator. Uma umqhubi eyala ukunyakaza, ingcindezi iyakheka. Lo mfutho ube usuvula ivalvu. Ivalvu ivumela kuphela uketshezi ukuthi luphume kwisilinda ngesivinini esilawulwayo. Uma umqhubi ekhulula isilawuli, ivalvu iyavala. Lesi senzo sivala umthwalo endaweni yawo. Siqinisekisa ukuthi umthwalo awusheshi ngaphezu kwesivinini esiphephile.

Izindlela Eziyinhloko Zokukhetha Ama-Valve Okuphikisana

Ukukhetha okulungileivalvu yokulinganisakubalulekile ekusebenzeni nasekuphepheni kohlelo. Onjiniyela kumele bacabangele izici eziningana. Lezi zici ziqinisekisa ukuthi ivalvu isebenza kahle ngaphakathi kokusetshenziswa kwayo okuhlosiwe.

Ukulinganisa Amandla Omthwalo kanye Nezilinganiso Zokucindezela

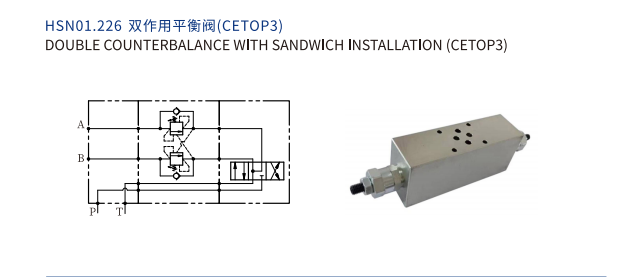

Abaklami besistimu kumele baqale bafanise umthamo womthwalo wevalvu yokulinganisa nomthwalo omkhulu ozowusekela. Lokhu kuqinisekisa ukuthi ivalvu ingakwazi ukubamba umthwalo ngokuphephile ngaphandle kokwehluleka. Badinga futhi ukucabangela izilinganiso zokucindezela. Umfutho ophezulu wokusebenza wevalvu kumele udlule umfutho ophezulu ozokhiqizwa uhlelo lwe-hydraulic. Lokhu kuvimbela umonakalo kuvalvu futhi kugcina ubuqotho besistimu. Isibonelo, ivalvu yokulinganisa kabili yeHanshang ye-HSN01.226 iphatha kufika kumabha angu-350. Lokhu kulinganisa kuyenza ifaneleke ukusetshenziswa kwemisebenzi enzima. Umfutho obekwe yivalvu kufanele okungenani ube ngokuphindwe ka-1.3 kunomfutho omkhulu womthwalo. Lokhu kunikeza umkhawulo wokuphepha.

Ukukhetha Isilinganiso Esifanele Sokuphenya Ama-Valve Okuphikisana

Isilinganiso somshayeli sithinta kakhulu izici zokulawula zevalvu yokulinganisa. Lesi silinganiso sinquma ukuthi kungakanani ukucindezela komshayeli okudingekayo ukuvula ivalvu. Isilinganiso somshayeli esiphansi sinikeza ukuzinza okukhulu. Sidinga ukucindezela komshayeli okwengeziwe ukuze sivuleke, okwenza ivalvu ingazweli kakhulu ekushintsheni kwengcindezi. Lokhu kulungele izinhlelo zokusebenza ezidingaukulawula umthwalo okunembile. Isilinganiso somshayeli esiphezulu sinikeza ukusebenza okubushelelezi. Sidinga ingcindezi encane yomshayeli ukuze uvule, okuvumela izikhathi zokuphendula ezisheshayo. Lokhu kuhambisana nezinhlelo zokusebenza lapho kudingeka khona ukunyakaza okusheshayo. Onjiniyela kumele bavumelanise isilinganiso somshayeli nezidingo ezithile zohlelo lokusebenza. Lokhu kuqinisekisa kokubili ukuzinza kanye nokuphendula.

Ukucabangela Izinga Lokugeleza Kokusebenza Kwe-Valve Yokuphikisana

Izinga lokugeleza ngevalvu yokulinganisa lithinta ngqo ukusebenza kwayo. Onjiniyela kumele bakhethe ivalvu enekhono lokugeleza elihambisana nezidingo zokugeleza eziphezulu zesistimu. Ivalvu encane ivimbela ukugeleza. Lokhu kungabangela ukukhiqizwa kokushisa ngokweqile kanye nokwehla kwengcindezi. Ivalvu enkulu kakhulu ingase iholele ekuphenduleni okuhamba kancane noma ekungazinzini. Usayizi ofanele uqinisekisa ukunyakaza koketshezi okuphumelelayo. Kuvimbela futhi ukugoba futhi kugcina ukusebenza kahle. Izindlela zangaphakathi zevalvu kumele zivumelane nokugeleza okulindelekile ngaphandle kokudala ukumelana okungadingekile.

Izici Zemvelo Nezokusetshenziswa Kwama-Valve Okuphikisana

Izimo zemvelo kanye nezidingo ezithile zohlelo lokusebenza nazo zithinta ukukhethwa kwamavalvu. Amazinga okushisa aphezulu, izindawo ezigqwalisayo, noma amazinga aphezulu okudlidliza adinga izinto ezikhethekile zamavalvu kanye nemiklamo. Isibonelo, izinhlelo zokusebenza zasolwandle zidinga izingxenye ezingamelani nokugqwala. Imishini ehambayo ingadinga amavalvu aklanyelwe ukumelana nokushaqeka nokudlidliza. Uhlobo loketshezi lwe-hydraulic olusetshenziswayo nalo ludlala indima. Ukuhambisana phakathi koketshezi kanye nezimbozo zamavalvu kubalulekile. Onjiniyela kumele futhi bacabangele isikhala esibonakalayo esitholakalayo sokufakwa. Imiklamo emincane, njenge-HSN01.226 yesitayela se-cartridge sikaHanshang, inikeza ukuguquguquka ezindaweni eziqinile. Lezi zici ziqinisekisa ukuthi ivalvu ephikisayo ekhethiwe isebenza ngokwethembeka kuyo yonke impilo yayo yokusebenza.

Umthelela Wezilinganiso Zomshayeli Ekulawuleni Amavalvu Okulwa Nebhalansi

Isilinganiso somshayeli siyipharamitha ebalulekile yokuklama yanoma iyiphiivalvu yokulinganisa. Kuthinta ngqo indlela ivalvu esabela ngayo ekucindezelweni kwesistimu. Lesi silinganiso sinquma inani lokucindezela komshayeli okudingekayo ukuvula ivalvu. Ukuqonda umthelela wayo kusiza onjiniyela ukuthi bathuthukise ukusebenza kwesistimu.

Izilinganiso Eziphansi Zokuhlola Ukuqina Okuthuthukisiwe

Isilinganiso somshayeli ophansi sinikeza ukuzinza okuphezulu kwezinhlelo ze-hydraulic. Lo mklamo udinga ukwanda okukhulu kwengcindezi yomshayeli ukuze uvule i-valve. Ngenxa yalokho, i-valve ayibe isazwela kakhulu ekushintsheni okuncane kwengcindezi. Lesi sici sivimbela ukunyakaza okungahlosiwe noma "ukuxokozela" ku-actuator. Izinhlelo ezisingatha imithwalo esindayo, elengayo zizuza kakhulu kuma-pilot ratios aphansi. Isibonelo, i-crane ephakamisa into enkulu idinga ukuzinza okuphezulu. Isilinganiso esiphansi siqinisekisa ukuthi umthwalo uhlala ubanjwe ngokuphephile. Uhamba kuphela uma umqhubi esebenzisa ingcindezi eyanele ngamabomu. Lo mklamo ubeka phambili ukuphepha kanye nokubekwa komthwalo okunembile.

Izilinganiso Eziphezulu Zomshayeli Wokusebenza Okushelelayo

Ngakolunye uhlangothi, isilinganiso esiphezulu somshayeli sikhuthaza ukusebenza okubushelelezi nokuphendulayo kakhudlwana. Lo mklamo udinga ingcindezi encane yomshayeli ukuze uvule ivalvu. Ivalvu isabela ngokushesha kakhulu ezinguqukweni zokucindezela kwesistimu. Lokhu kuvumela ukunyakaza okumanzi nokuqhubekayo kwe-actuator. Izinhlelo zokusebenza ezifuna ukujikeleza okusheshayo nokubushelelezi zivame ukusebenzisa izilinganiso eziphezulu zomshayeli. Cabanga ngomshini owenza imisebenzi ephindaphindayo, elula. Isilinganiso esiphezulu somshayeli sinciphisa ukunyakaza okukhungathekile. Inikeza ulwazi lomsebenzisi olukhululekile nolusebenzayo. Lo mklamo ulungiselela isivinini kanye nokugeleza kokusebenza.

Ukuvumelanisa Isilinganiso Somshayeli Nezidingo Zesicelo

Ukukhetha isilinganiso esifanele sokuhlola kuyisinqumo esibalulekile sobunjiniyela. Kuhilela ukulinganisela isidingo sokuzinza nesifiso sokusebenza kahle. Onjiniyela kumele bahlole ngokucophelela izidingo ezithile zesicelo.

- Imithwalo Enzima, Ebucayi: Izinhlelo zokusebenza ezifaka imithwalo esindayo, engaba yingozi zidinga isilinganiso esiphansi sokuhlola. Lokhu kuqinisekisa ukulawula okuphezulu futhi kuvimbela ukuphunyuka komthwalo ngengozi.

- Imisebenzi Elula, Ephindaphindayo: Izinhlelo ezenza ukunyakaza okulula nokuvamile ziyazuza ngesilinganiso esiphezulu sokuhlola. Lokhu kunikeza izikhathi zokuphendula ezisheshayo kanye noshintsho olubushelelezi.

- Izimo Eziguqukayo: Ezinye izinhlelo zokusebenza zihlangabezana nezimo zomthwalo ezihlukene. Onjiniyela bangase bakhethe isilinganiso sokuhlola esimaphakathi. Lokhu kunikeza ukuvumelana phakathi kokuqina nokuphendula.

Isilinganiso se-pilot esifanele sithinta ngqo ukusebenza kahle kwesistimu kanye nokuphepha kwayo. Isilinganiso esikhethwe kahle siqinisekisa ukuthi i-valve yokulinganisa ibhalansi yenza umsebenzi wayo ngokwethembeka. Siphinde sibe negalelo ebude besikhathi sokuphila kwesistimu.uhlelo lwe-hydraulic.

Ukuxazulula Izinkinga Ezivamile Zokuphikisana Ne-Valve

Izinhlelo ze-hydraulicbathembele ekusebenzeni kahle kwe-valve. Abaqhubi bavame ukubhekana nezinkinga ezithile ngalezi zingxenye. Ukuhlonza nokuxazulula lezi zinkinga kugcina ngokushesha ukusebenza kahle kwesistimu nokuphepha.

Ukubhekana Nengxoxo Nokungazinzile Kwe-Valve Yokuphikisana

Ukukhuluma noma ukungahlaliseki kubonisa inkinga ngokusebenza kwevalvu. Lokhu kuvame ukubangelwa ukulungiselelwa kwesilinganiso somshayeli esingalungile. Ngezinye izikhathi, umoya ohlelweni lwe-hydraulic ubangela ukunyakaza okungaguquki. Uketshezi olungcolile lungaphazamisa futhi ukusebenza kwevalvu ebushelelezi. Ochwepheshe kufanele baqinisekise ukuthi isilinganiso somshayeli sihambisana nezidingo zohlelo lokusebenza. Kumelwe bakhiphe umoya ohlelweni. Ukuhlunga uketshezi njalo kuvimbela ukungcola. Ukulungisa i-orifice yokudambisa kungaqinisa nokusabela kwevalvu.

Ukuxazulula Ukukhukhuleka Komthwalo Nokucwila Kuma-Valve Okuphikisana

Ukukhukhuleka komthwalo noma ukukhukhuleka kusho ukuthi i-actuator ihamba kancane ngaphandle komyalo. Ukuvuza kwangaphakathi ngaphakathi kwevalvu kuvame ukubangela le nkinga. Izivalo ezigugile noma izihlalo zevalvu ezonakele zivumela uketshezi ukuthi ludlule. Ukusetha ingcindezi okungalungile nakho kungabangela ukukhukhuleka. Abasebenzi bokulungisa kufanele bahlole izivalo zevalvu ukuthi azigugile. Kumele bashintshe noma yiziphi izingxenye ezonakele. Ukulinganisa kabusha ukusetha ingcindezi yevalvu kuqinisekisa ukubamba umthwalo ngendlela efanele.

Ukuphatha Ukushisa Okudlulele Nokukhuphuka Kokucindezela

Ukushisa okweqile kanye nokukhuphuka kwengcindezi okungazelelwe kulimaza izinhlelo ze-hydraulic. I-valve engakhuli kakhulu ingavimbela ukugeleza, ikhiqize ukushisa. Ukujikeleza okusheshayo kwe-actuator nakho kunegalelo ekushiseni ngokweqile. Ukukhuphuka kwengcindezi kuvame ukwenzeka ngenxa yokushintsha komthwalo okungazelelwe noma ukulungiswa okungafanele kwe-valve. Onjiniyela kufanele baqinisekise ukuthi i-valve inosayizi ofanele wesilinganiso sokugeleza kwesistimu. Bangafaka i-heat exchanger enkulu ukuphatha izinga lokushisa. Ukulungisa izilungiselelo ze-valve yokusiza kusiza ekunciphiseni ukukhuphuka kwengcindezi.

Ukuhlonza Ukuvuza Kwangaphandle Nokungcola

Ukuvuza kwangaphandle kuwukulahleka koketshezi okubonakalayo eduze kwevalvu. Lokhu kuvame ukukhomba kuma-O-rings alimele noma izinto zokubopha ezikhululekile. Ukungcola, nakuba kungabonakali ngaso sonke isikhathi ngaphandle, kubonakala njengokusebenza kancane noma ukuguguleka ngaphambi kwesikhathi. Ochwepheshe kumele baqinise zonke izixhumanisi. Kufanele bashintshe izivalo ezigugile noma eziqhekekile ngokushesha. Ukuhlaziywa koketshezi okuvamile kanye nokushintsha kwezihlungi kuvimbela ukungcola ekulimaleni izingxenye zangaphakathi.

Intuthuko kubuchwepheshe be-Counterbalance Valve

Ubuchwepheshe besistimu ye-hydraulic buhlala buthuthuka.Abakhiqizi bethula izici ezintshaLokhu kusungula izinto ezintsha kuthuthukisa ukusebenza kahle, ukusebenza kahle kanye nokuthembeka.

Izixazululo ze-Smart Counterbalance Valve ezihlanganisiwe

Imiklamo yesimanje ifaka izici ezihlakaniphile. Lezi zixazululo zivame ukufaka izinzwa ezifakiwe. Izinzwa ziqapha ingcindezi, izinga lokushisa, kanye nokugeleza ngesikhathi sangempela. Zidlulisela idatha ezinhlelweni zokulawula. Lokhu kuvumela ukulungiswa kokubikezela. Abasebenzi bangabona izinkinga ezingaba khona ngaphambi kokuba kwenzeke ukwehluleka. Lokhu kuhlanganiswa kuthuthukisa isikhathi sokusebenza kwesistimu.

Imiklamo Yamavalvu Okumelana Nebhalansi Esebenza Kahle

Imiklamo emisha ibeka phambili ukongiwa kwamandla. Onjiniyela benza ngcono izindlela zokugeleza kwangaphakathi. Lokhu kunciphisa ukwehla kwengcindezi kulo lonke i-valve. Ukwehla kwengcindezi okuphansi kusho ukulahlekelwa amandla okuncane. Le miklamo iphinde inciphise ukukhiqizwa kokushisa. Lokhu kunegalelo ekusebenzeni kahle kwesistimu iyonke. Kuphinde kwandise isikhathi sokuphila koketshezi lwe-hydraulic kanye nezingxenye.

Ukusungula Izinto Ezintsha Ezintweni Zokumelana Nokuqina Kwevalvu

Isayensi yezinto ezibonakalayo iqhuba ukuthuthuka okukhulu. Abakhiqizi basebenzisa ama-alloy athuthukile kanye nezingubo ezikhethekile. Lezi zinto zimelana nokuguguleka kangcono. Zimelana nezimo zokusebenza ezinzima. Lokhu kuthuthukisa ukuqina kwevalvu yokulinganisa. Kuphinde kwandise isikhathi sayo sokusebenza. Lokhu kunciphisa imvamisa yokulungisa kanye nezindleko.

Ukuhlanganiswa Kokulawula Kwedijithali Kwama-Valve Okuphikisana

Izinhlelo zokulawula zedijithali zinikeza ukuphathwa okunembile. Ukusebenza kwevalvu yokulawula amasignali kagesi. Lokhu kuvumela ukulungiswa kahle kwamapharamitha okusebenza. Abasebenzi bangalungisa izilungiselelo kude. Ukuhlanganiswa kwedijithali kuvumela ukulawula okuguquguqukayo. Uhlelo lungasabela ngokuguquguqukayo ezimweni zomthwalo ezishintshayo. Lokhu kunikeza ukulawula okuphezulu kanye nokuguquguquka.

Izindlela Ezinhle Kakhulu Zokufaka Nokulungisa Amavalvu Okumelana Nebhalansi

Ukufakwa okufanele kanye nokugcinwa njalo kuqinisekisa ukusebenza kahle kanye nobude besikhathi sezingxenye ze-hydraulic. Le mikhuba ivimbela isikhathi sokungasebenzi esibizayo futhi ithuthukisa ukuphepha kohlelo.

Amasu Okufaka Afanele Ama-Valve Okuphikisana

Abafaki kumele bafake ama-valve ngokuphephile. Kufanele balandele izincazelo zomkhiqizi zezilungiselelo ze-torque. Qinisekisa ukuxhumeka kwe-port efanele. Amapayipi angalungile angaholela ekungasebenzi kahle kwesistimu. Sebenzisa izithiyo zokuvala izintambo ezifanele. Gwema ukuqinisa kakhulu izinsimbi. Lokhu kuvimbela umonakalo emizimbeni yama-valve noma emachwebeni. Hlanza yonke imigqa ye-hydraulic ngaphambi kokufaka. Izinto ezingcolisayo zingabangela izinkinga zokusebenza ngokushesha.

Ukuhlolwa Okuvamile Nokuhlolwa Kwama-Counterbalance Valve

Abaqhubi kufanele benze ukuhlola okubonakalayo njalo. Bheka izimpawu zokuvuza kwangaphandle. Hlola ukugqwala noma umonakalo ongokwenyama. Lalela imisindo engavamile ngesikhathi sokusebenza. Ochwepheshe kumele bahlole ukusebenza kwe-valve njalo. Baqinisekisa izilungiselelo zokucindezela ezifanele. Baqinisekisa nokusebenza okubushelelezi ngaphansi komthwalo. Bhala phansi yonke imiphumela yokuhlola nokuhlola. Lokhu kudala umlando wokulungisa obalulekile.

Ukusungula Amashejuli Okulungisa Okuvimbelayo

Sebenzisa isimiso sokulungisa esiqinile sokuvimbela. Lokhu kufaka phakathi ukuhlaziywa koketshezi okuvamile. Shintsha izihlungi ze-hydraulic ngezikhathi ezinconywayo. Shintsha izivalo nama-O-ring ngaphambi kokuba zehluleke. I-Hanshang itusa izikhathi ezithile zesevisi yemikhiqizo yayo. Ukunamathela kulezi zinhlelo kunciphisa ukuphazamiseka okungalindelekile. Kuphinde kwandise isikhathi sokuphila sohlelo lonke lwe-hydraulic.

Iziqondiso Zokushintsha Ingxenye Ye-Valve Yokuphikisana

Shintsha izingxenye ezigugile noma ezonakele ngokushesha. Sebenzisa izingxenye zangempela zomkhiqizi kuphela. Lokhu kuqinisekisa ukuhambisana nokusebenza kahle. Ochwepheshe kufanele balandele amabhukwana esevisi anemininingwane yokuwahlukanisa nokuhlanganisa kabusha. Linganisa ivalvu ngemva kwanoma yikuphi ukushintsha ingxenye enkulu. Ukushintsha okufanele kuvimbela ukwehluleka kokwehla. Kugcina ubuqotho nokuphepha kohlelo.

Ukukhetha ama-valve ahambisanayo anolwazi kubaluleke kakhulu ezinhlelweni ze-hydraulic. Kuholela ngqo ekusebenzeni kahle okuphezulu, ukuzinza kokusebenza okuthuthukisiwe, kanye nokuphepha okuphezulu. Ochwepheshe kumele bafunde njalo ngalezi zingxenye ezibalulekile zesistimu ye-hydraulic. Lolu lwazi oluqhubekayo luqinisekisa ukusebenza okuphezulu kanye nokuthembeka.

Imibuzo Evame Ukubuzwa

Uyini umsebenzi oyinhloko wevalvu yokulinganisa?

A ivalvu yokulinganisaIvimbela kakhulu ukunyakaza komthwalo okungalawuleki. Igcina umthwalo endaweni yawo futhi ilawula isivinini sokwehla kwawo. Lokhu kuqinisekisa ukuphepha nokuqina kohlelo.

Isilinganiso somshayeli sithinta kanjani ukusebenza kwevalvu?

Isilinganiso somshayeli sithonya ukuzwela kwevalvu. Isilinganiso esiphansi sithuthukisa ukuzinza, kanti isilinganiso esiphezulu sinikeza ukusebenza okubushelelezi. Onjiniyela bavumelanisa isilinganiso nezidingo zohlelo lokusebenza.

Yiziphi izimpawu ezivamile zevalvu yokumelana engasebenzi kahle?

Izimpawu ezivamile zifaka phakathi ukuzulazula komthwalo, ukuxokozela, noma ukungazinzi. Ukuvuza kwangaphandle kanye nokushisa ngokweqile nakho kubonisa izinkinga ezingaba khona. Ukuxilongwa okusheshayo kuvimbela ukulimala okwengeziwe kohlelo. ⚠️