Efanelekileyoivalvu yokulinganisaUkukhetha kuqinisekisa ukhuseleko olubalulekileyo kwinkqubo. Kuthintela umthwalo ongalawulekiyo kwaye kugcina ulawulo. Ivalvu efanelekileyo yokulinganisa inyusa uzinzo lokusebenza, inika intshukumo egudileyo. Olu khetho luqhagamshela ngokuthe ngqo kuyo yonke intoi-hydraulicukusebenza kakuhle kwenkqubo.Hanshanginika izinto ezinokuthenjwa.

Izinto ezibalulekileyo ekufuneka ziqwalaselwe

- Iivalvu zokulinganisela zibalulekile kukhuseleko. Zithintela imithwalo enzima ukuba ingawi ngokukhawuleza. Zikwagcina imithwalo izinzile.

- Ukukhetha ivalvu efanelekileyo kubalulekile. Dibanisa amandla ayo nomthwalo wakho. Kwakhona, khetha umlinganiselo ofanelekileyo wepilot ukuze ukwazi ukuhamba ngokuthe ngcembe okanye ngokutyibilikayo.

- Jonga kwaye unakekele iivalvu zakho rhoqo. Khangela ukuvuza okanye izandi ezingaqhelekanga. Oku kuncedainkqubo ye-hydraulicisebenza kakuhle kwaye ihlala ixesha elide.

Ukuqonda iValve yokuPhinda-phinda

Yintoni iValve yokuBalana?

A ivalvu yokulinganisa ibhalansi yinxalenye ebalulekileyokwiinkqubo ze-hydraulic. Isebenza njengesixhobo sokhuseleko. Le valve igcina ulawulo kwi-hydraulic actuator, ingakumbi xa ixhasa umthwalo. Ithintela intshukumo engalawulekiyo. Ivalvu iqinisekisa ukuba umthwalo uhlala uzinzile.

Imisebenzi Ephambili yeValve Yokuchasana

Le valve yenza imisebenzi emininzi ebalulekileyo. Igcina umthwalo kwindawo yawo. Oku kuthintela umthwalo ukuba ungakhukuliseki okanye uwe. I valve ikwancedailawula isantya somthwalo owehlayo. Idala uxinzelelo lwasemva, olulawula ukuhamba kwegazi kwi-actuator. Ngaphezu koko, ithintela i-cavitation kwisilinda ye-hydraulic. I-cavitation inokonakalisa inkqubo. Ivalvu echaseneyo iqinisekisa intshukumo egudileyo nelawulwayo.

Indlela iiValve zeCounterbalance ezithintela ngayo ukubaleka komthwalo

Ukubaleka komthwalo kwenzeka xa umthwalo onzima uhamba ngokungalawulekiyo ngenxa yomxhuzulane. Ivalvu echaseneyo ithintela le meko iyingozi. Ifuna uxinzelelo lomqhubi ukuze ivuleke. Olu xinzelelo lomqhubi luvela kwicala lokungena le-actuator. Xa umqhubi eyalela intshukumo, uxinzelelo luyanda. Olu xinzelelo luvula ivalvu. Ivalvu ivumela kuphela ulwelo ukuba luphume kwisilinda ngesantya esilawulwayo. Ukuba umqhubi ukhulula ulawulo, ivalvu iyavala. Eli nyathelo livala umthwalo endaweni yawo. Liqinisekisa ukuba umthwalo awukhawulezi ngaphaya kwesantya esikhuselekileyo.

Iikhrayitheriya eziphambili zoKhetho lweValve yokuBalana

Ukukhetha okuchanekileyoivalvu yokulinganisaKubalulekile ekusebenzeni nasekukhuselekeni kwenkqubo. Iinjineli kufuneka ziqwalasele izinto ezininzi. Ezi zinto ziqinisekisa ukuba ivalvu isebenza ngokufanelekileyo ngokwendlela ekucetywayo ukuba isetyenziswe ngayo.

Ubungakanani boMthwalo oQhagamshelwanayo kunye noVavanyo loXinzelelo

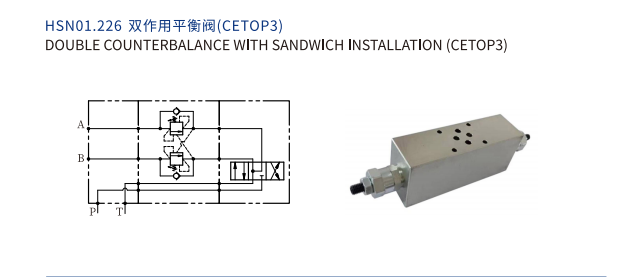

Abayili benkqubo kufuneka baqale bafanise umthamo womthwalo wevalvu echaseneyo nomthwalo omkhulu oza kuwuxhasa. Oku kuqinisekisa ukuba ivalvu iyakwazi ukubamba umthwalo ngokukhuselekileyo ngaphandle kokusilela. Kwakhona kufuneka baqwalasele ukulinganiswa koxinzelelo. Uxinzelelo oluphezulu lokusebenza kwevalvu kufuneka ludlule uxinzelelo oluphezulu oluza kuveliswa yinkqubo ye-hydraulic. Oku kuthintela umonakalo kwivalvu kwaye kugcina ukuthembeka kwenkqubo. Umzekelo, ivalvu ephikisanayo yeHanshang yeHSN01.226 iphatha ukuya kuthi ga kwi-350 bar. Olu vavanyo lwenza ukuba ifaneleke kwizicelo ezinzima. Uxinzelelo olubekwe yivalvu kufuneka lube ubuncinane ngokuphindwe ka-1.3 koxinzelelo oluphezulu lomthwalo. Oku kubonelela ngomda wokhuseleko.

Ukukhetha i-Optimal Pilot Ratio yee-Counterbalance Valves

Umlinganiselo wepilot uchaphazela kakhulu iimpawu zolawulo lwevalvu echaseneyo. Lo mlinganiselo umisela ukuba kufuneka uxinzelelo olungakanani lwepilot ukuvula ivalvu. Umlinganiselo wepilot ophantsi unika uzinzo olukhulu. Udinga uxinzelelo olungaphezulu lwepilot ukuvula, okwenza ivalvu ingathinteli kakhulu kutshintsho loxinzelelo. Oku kulungele izicelo ezifunaulawulo lomthwalo oluchanekileyo. Umlinganiselo ophezulu womqhubi ubonelela ngokusebenza okubushelelezi. Kufuna uxinzelelo oluncinci lomqhubi ukuze uvuleke, okuvumela amaxesha okuphendula akhawulezileyo. Oku kuhambelana nezicelo apho kufuneka intshukumo ekhawulezileyo. Iinjineli kufuneka zilungelelanise umlinganiselo womqhubi neemfuno ezithile zesicelo. Oku kuqinisekisa ukuzinza kunye nokuphendula.

Ukuqwalasela iSayithi yokuHamba koMsebenzi weValve yokuHlangana

Izinga lokuhamba kwe-valve echasene ne-counterbalance lichaphazela ngqo ukusebenza kwayo. Iinjineli kufuneka zikhethe i-valve enomthamo wokuhamba ohambelana neemfuno eziphezulu zokuhamba kwe-system. I-valve encinci ithintela ukuhamba. Oku kunokubangela ukuveliswa kobushushu obugqithisileyo kunye nokwehla koxinzelelo. I-valve enkulu kakhulu inokukhokelela ekuphenduleni okucothayo okanye ekungazinzini. Ubungakanani obufanelekileyo buqinisekisa ukuhamba kakuhle kolwelo. Ikwathintela ukuxinana kwe-cavitation kwaye igcina ukusebenza kakuhle. Iindlela zangaphakathi ze-valve kufuneka zilungele ukuhamba okulindelweyo ngaphandle kokudala ukumelana okungafanelekanga.

Izinto ezichaphazela indalo kunye nokusetyenziswa kweeValve zokuchasana

Iimeko zokusingqongileyo kunye neemfuno ezithile zesicelo nazo zichaphazela ukukhethwa kweevalvu. Amaqondo obushushu aphezulu, iindawo ezirhabaxa, okanye amanqanaba aphezulu okungcangcazela afuna izixhobo kunye noyilo olukhethekileyo lweevalvu. Umzekelo, usetyenziso lwaselwandle lufuna izinto ezinganyangekiyo kukugqwala. Oomatshini abahambahambayo banokufuna iivalvu ezenzelwe ukumelana nokugqwala nokungcangcazela. Uhlobo lolwelo lwe-hydraulic olusetyenziswayo nalo ludlala indima. Ukuhambelana phakathi kolwelo kunye nezitywino zeevalvu kubalulekile. Iinjineli kufuneka ziqwalasele nendawo ebonakalayo ekhoyo yokufakelwa. Uyilo oluncinci, njenge-HSN01.226 ye-cartridge kaHanshang, lubonelela ngokuguquguquka kwiindawo ezixineneyo. Ezi zinto ziqinisekisa ukuba ivalvu echaseneyo ekhethiweyo isebenza ngokuthembekileyo kulo lonke ixesha layo lokusebenza.

Impembelelo yeeRatio zePilot kuLawulo lweeValve ezichaseneyo

Umlinganiselo we-pilot yiparameter ebalulekileyo yoyilo kuyo nayiphi naivalvu yokulinganisa. Ichaphazela ngokuthe ngqo indlela ivalvu ephendula ngayo kuxinzelelo lwenkqubo. Olu linganiselo lumisela ubungakanani boxinzelelo lomqhubi olufunekayo ukuvula ivalvu. Ukuqonda impembelelo yayo kunceda iinjineli ukuba ziphucule ukusebenza kwenkqubo.

IiRatio eziPhantsi zoMlingo woQinisekiso oluPhuculweyo

Umlinganiselo ophantsi womqhubi ubonelela ngozinzo oluphezulu kwiinkqubo ze-hydraulic. Olu yilo lufuna ukonyuka okukhulu koxinzelelo lomqhubi ukuze kuvulwe ivalvu. Ngenxa yoko, ivalvu ayibi namvakalelo kangako kutshintsho oluncinci loxinzelelo. Olu phawu luthintela intshukumo engalindelekanga okanye "ukuxokozela" kwi-actuator. Iinkqubo ezisingatha imithwalo enzima, exhonyiweyo zixhamla kakhulu kumlinganiselo ophantsi womqhubi. Umzekelo, i-crane ephakamisa into enkulu idinga uzinzo oluphezulu. Umlinganiselo ophantsi uqinisekisa ukuba umthwalo uhlala ubanjwe ngokukhuselekileyo. Uhamba kuphela xa umqhubi esebenzisa ngabom uxinzelelo olwaneleyo. Olu yilo lubeka phambili ukhuseleko kunye nokubekwa komthwalo ngokuchanekileyo.

Iireyithingi eziphezulu zoMsebenzi oLungeleleneyo

Ngokwahlukileyo koko, umlinganiselo ophezulu womqhubi ukhuthaza ukusebenza okubushelelezi nokuphendula ngakumbi. Olu yilo lufuna uxinzelelo oluncinci lomqhubi ukuvula ivalvu. Ivalvu isabela ngokukhawuleza kutshintsho kuxinzelelo lwenkqubo. Oku kuvumela intshukumo emanzi ngakumbi neqhubekayo ye-actuator. Ii-aplikeshini ezifuna ukujikeleza ngokukhawuleza nangokutyibilikayo zihlala zisebenzisa umlinganiselo ophezulu womqhubi. Cinga ngomatshini owenza imisebenzi ephindaphindayo, elula. Umlinganiselo ophezulu womqhubi unciphisa iintshukumo eziguquguqukayo. Ibonelela ngamava omsebenzisi akhululekileyo nasebenzayo. Olu yilo lulungiselela isantya kunye nokuguquguquka kokusebenza.

Ukulungelelanisa umlinganiselo wePilot neemfuno zesicelo

Ukukhetha umlinganiselo ochanekileyo wovavanyo sisigqibo esibalulekileyo sobunjineli. Kubandakanya ukulinganisela imfuneko yozinzo ngokuchasene nomnqweno wokusebenza kakuhle. Iinjineli kufuneka zihlole ngononophelo iimfuno ezithile zesicelo.

- Imithwalo Enzima, Ebalulekileyo: Izicelo ezibandakanya imithwalo enzima, enokuba yingozi zifuna umlinganiselo ophantsi wovavanyo. Oku kuqinisekisa ulawulo oluphezulu kwaye kuthintela ukubaleka komthwalo ngengozi.

- Imisebenzi elula, ephindaphindwayo: Iinkqubo ezisebenza ngokunyakaza okulula, rhoqo ziyazuza kumlinganiselo ophezulu wovavanyo. Oku kubonelela ngamaxesha okuphendula akhawulezayo kunye notshintsho olugudileyo.

- Iimeko ezitshintshayoEzinye ii-aplikeshini zihlangabezana neemeko ezahlukeneyo zomthwalo. Iinjineli zinokukhetha umlinganiselo we-pilot ophakathi. Oku kunika intsebenziswano phakathi kozinzo kunye nokuphendula.

Umlinganiselo ofanelekileyo we-pilot uchaphazela ngokuthe ngqo ukusebenza kakuhle kwenkqubo kunye nokhuseleko. Umlinganiselo okhethwe kakuhle uqinisekisa ukuba ivalvu echaseneyo yenza umsebenzi wayo ngokuthembekileyo. Ikwanegalelo kubomi obude bexeshainkqubo ye-hydraulic.

Ukusombulula iingxaki zeValve eziQhelekileyo zokuBalana

Iinkqubo ze-hydraulicxhomekeke ekusebenzeni kakuhle kwevalvu. Abaqhubi badla ngokudibana neengxaki ezithile ngezi zinto. Ukuchonga nokusombulula ezi ngxaki ngokukhawuleza kugcina ukusebenza kakuhle kwenkqubo kunye nokhuseleko.

Ukujongana neNgxoxo kunye nokungazinzi kweValve yokuPhikisana

Ukuxokozela okanye ukungazinzi kubonisa ingxaki yokusebenza kwevalvu. Oku kudla ngokubangelwa kukuseta i-pilot ratio engalunganga. Ngamanye amaxesha, umoya kwinkqubo ye-hydraulic ubangela intshukumo engaguqukiyo. Ulwelo olungcolisiweyo lunokuthintela ukusebenza kwevalvu egudileyo. Iingcali kufuneka ziqinisekise ukuba i-pilot ratio ihambelana neemfuno zesicelo. Kufuneka zikhuphe umoya kwinkqubo. Ukuhluzwa kolwelo rhoqo kuthintela ungcoliseko. Ukulungisa i-orifice yokudambisa kunokuzinzisa impendulo yevalvu.

Ukusombulula ukuHamba koMthwalo kunye nokuHamba kwiiValve zokuBambana

Ukutyibilika okanye ukuqhekeka komthwalo kuthetha ukuba i-actuator ihamba kancinci ngaphandle komyalelo. Ukuvuza kwangaphakathi ngaphakathi kwivalvu kuhlala kubangela le ngxaki. Izitywino ezigugileyo okanye izihlalo zevalvu ezonakeleyo zivumela ulwelo ukuba ludlule. Ukuseta uxinzelelo olungalunganga nako kunokubangela ukutyibilika. Abasebenzi bokulungisa kufuneka bahlole izitywino zevalvu ukuba azigugi. Kufuneka batshintshe naziphi na izinto ezonakeleyo. Ukulinganisa kwakhona useto loxinzelelo lwevalvu kuqinisekisa ukubamba umthwalo ngokufanelekileyo.

Ukulawula Ubushushu Obugqithisileyo kunye Nokunyuka Koxinzelelo

Ubushushu obugqithisileyo kunye nokujika koxinzelelo ngequbuliso konakalisa iinkqubo ze-hydraulic. Ivalvu engakhuliyo inokuthintela ukuhamba, ivelise ubushushu. Ukujikeleza ngokukhawuleza kwe-actuator nako kunegalelo ekutshiseni kakhulu. Ukujika koxinzelelo kudla ngokubangelwa kukutshintsha komthwalo ngequbuliso okanye ukulungiswa okungafanelekanga kwevalvu. Iinjineli kufuneka ziqinisekise ukuba ivalvu inobungakanani obuchanekileyo ngokwezinga lokuhamba kwenkqubo. Banokufaka i-heat exchanger enkulu ukulawula ubushushu. Ukulungisa useto lwevalvu yokunceda kunceda ukunciphisa ukujika koxinzelelo.

Ukuchonga Ukuvuza Kwangaphandle kunye Nongcoliseko

Ukuvuza kwangaphandle kukulahleka kolwelo okubonakalayo okujikeleze ivalvu. Oku kudla ngokubonisa ii-O-rings ezonakeleyo okanye izixhobo ezikhululekileyo. Ungcoliseko, nangona lungabonakali rhoqo ngaphandle, lubonakala ngokucothayo okanye ukuguguleka kwangaphambi kwexesha. Iingcali kufuneka ziqinise zonke izihlanganisi. Zifanele zitshintshe izitywini ezigugileyo okanye eziqhekekileyo ngoko nangoko. Uhlalutyo oluqhelekileyo lolwelo kunye notshintsho lwezihluzo luthintela ungcoliseko ekonakaliseni izinto zangaphakathi.

Uphuhliso kwiTekhnoloji yeValve yokuBalana

Iteknoloji yenkqubo ye-hydraulic iyaqhubeka nokutshintsha.Abavelisi bazisa izinto ezintshaEzi zinto zintsha ziphucula ukusebenza, ukusebenza kakuhle, kunye nokuthembeka.

Izisombululo zeValve eziHlanganisiweyo zeSmart Counterbalance

Uyilo lwanamhlanje luquka iimpawu ezikrelekrele. Ezi zisombululo zihlala ziquka izinzwa ezifakwe ngaphakathi. Izinzwa zijonga uxinzelelo, ubushushu, kunye nokuhamba ngexesha langempela. Zithumela idatha kwiinkqubo zolawulo. Oku kuvumela ukugcinwa kwangaphambili. Abaqhubi banokuchonga iingxaki ezinokubakho ngaphambi kokuba kwenzeke ukungasebenzi kakuhle. Olu dibaniso luphucula ukusebenza kwenkqubo.

Uyilo lweeValve zokuBalana eziSebenza kakuhle ngamandla

Uyilo olutsha lubeka phambili ukugcinwa kwamandla. Iinjineli ziphucula iindlela zokuhamba kwamanzi ngaphakathi. Oku kunciphisa ukwehla koxinzelelo kwivalvu. Ukwehla koxinzelelo okuphantsi kuthetha ukulahleka kwamandla okuncinci. Olu yilo lukwanciphisa ukuveliswa kobushushu. Oku kuncedisa ekusebenzeni kakuhle kwenkqubo iyonke. Kwakhona kwandisa ubomi bolwelo lwe-hydraulic kunye neenxalenye.

Utshintsho kwizixhobo zeValve ezichaseneyo kunye nokuqina

Isayensi yezinto eziphathekayo iqhuba uphuculo olukhulu. Abavelisi basebenzisa ii-alloys eziphambili kunye neengubo ezikhethekileyo. Ezi zinto zimelana nokuguguleka ngcono. Zimelana neemeko zokusebenza ezinzima. Oku kwandisa ukuqina kwevalvu echaseneyo. Ikwandisa ubomi bayo benkonzo. Oku kunciphisa amaxesha okugcinwa kunye neendleko.

Ukuhlanganiswa koLawulo lweDijithali kwiiValve zokuBalana

Iinkqubo zolawulo lwedijithali zibonelela ngolawulo oluchanekileyo. Ukusebenza kwevalvu yokulawula imiqondiso ye-elektroniki. Oku kuvumela ukulungiswa kakuhle kweeparamitha zokusebenza. Abaqhubi banokulungisa useto kude. Ukuhlanganiswa kwedijithali kwenza ulawulo oluhambelanayo. Inkqubo inokuphendula ngokuguquguqukayo kwiimeko zomthwalo ezitshintshayo. Oku kubonelela ngolawulo oluphezulu kunye nokuguquguquka.

Iindlela ezilungileyo zokufaka kunye nokulungisa iivalvu ezichasene nebhalansi

Ukufakwa ngokufanelekileyo kunye nokugcinwa rhoqo kuqinisekisa ukusebenza kakuhle kunye nobude bexesha lezinto ze-hydraulic. Ezi ndlela zithintela ukungasebenzi okubizayo kwaye ziphucula ukhuseleko lwenkqubo.

Iindlela ezifanelekileyo zokufakela iiValve zokuBalana

Abafaki-zixhobo kufuneka bafake iivalvu ngokukhuselekileyo. Bafanele balandele iinkcukacha zomenzi malunga noseto lwe-torque. Qinisekisa ukuba uqhagamshelo oluchanekileyo lwee-port. Ukufakelwa kwepayipi ngendlela engalunganga kunokubangela ukungasebenzi kakuhle kwenkqubo. Sebenzisa izitywini zentambo ezifanelekileyo. Kuphephe ukuqinisa kakhulu izixhobo. Oku kuthintela umonakalo kwimizimba yeevalvu okanye kwii-port. Coca yonke imigca ye-hydraulic ngaphambi kokufakwa. Izinto ezingcolisayo zinokubangela iingxaki zokusebenza kwangoko.

Ukuhlolwa rhoqo kunye nokuvavanywa kweeValve zokulinganisa ibhalansi

Abaqhubi kufuneka benze uhlolo olubonakalayo rhoqo. Khangela iimpawu zokuvuza kwangaphandle. Jonga ukugqwala okanye umonakalo womzimba. Mamela iingxolo ezingaqhelekanga ngexesha lokusebenza. Iingcali kufuneka zivavanye ukusebenza kwevalvu rhoqo. Ziqinisekisa useto oluchanekileyo loxinzelelo. Zikwaqinisekisa ukusebenza kakuhle phantsi komthwalo. Bhala phantsi zonke iziphumo zovavanyo kunye novavanyo. Oku kudala imbali ebalulekileyo yolondolozo.

Ukuseka iiShedyuli zoLondolozo loThintelo

Sebenzisa ishedyuli yokulungisa engqongqo yokuthintela. Oku kuquka uhlalutyo oluqhelekileyo lolwelo. Tshintsha izihluzi ze-hydraulic ngamaxesha acetyiswayo. Tshintsha izitywino kunye nee-O-rings ngaphambi kokuba zingasebenzi. UHanshang ucebisa amaxesha athile enkonzo kwiimveliso zakhe. Ukunamathela kwezi shedyuli kunciphisa ukonakala okungalindelekanga. Kwakhona kwandisa ubomi benkqubo yonke ye-hydraulic.

Izikhokelo zokutshintshwa kweCandelo leValve yokuBalance

Buyisela izinto ezigugileyo okanye ezonakeleyo ngokukhawuleza. Sebenzisa kuphela iindawo zomenzi zokwenyani. Oku kuqinisekisa ukuhambelana nokusebenza. Iingcali kufuneka zilandele iincwadana zeenkonzo ezineenkcukacha zokuqhaqha nokudibanisa kwakhona. Lungisa ivalvu emva kokutshintshwa kwenxalenye enkulu. Ukutshintshwa ngokufanelekileyo kuthintela ukungaphumeleli kokwehla. Kugcina inkqubo icocekile kwaye ikhuselekile.

Ukukhetha iivalvu ezichasene nokulinganisela kubalulekile kwiinkqubo ze-hydraulic. Oku kukhokelela ngokuthe ngqo ekusebenzeni kakuhle, uzinzo oluphuculweyo lokusebenza, kunye nokhuseleko oluphezulu. Iingcali kufuneka ziqhubeke zifunda ngezi zinto zibalulekileyo zenkqubo ye-hydraulic. Olu lwazi luqhubekayo luqinisekisa ukusebenza okuphezulu kunye nokuthembeka.

FAQ

Yintoni umsebenzi oyintloko wevalvu yokulinganisa?

A ivalvu yokulinganisaIthintela kakhulu intshukumo yomthwalo engalawulekiyo. Igcina umthwalo kwindawo yayo kwaye ilawula isantya sokuhla kwayo. Oku kuqinisekisa ukhuseleko kunye nozinzo lwenkqubo.

Umlinganiselo we-pilot uchaphazela njani ukusebenza kwevalvu?

Umlinganiselo wepilot uchaphazela uvakalelo lwevalvu. Umlinganiselo ophantsi uphucula uzinzo, ngelixa umlinganiselo ophezulu ubonelela ngokusebenza okubushelelezi. Iinjineli zilungelelanisa umlinganiselo neemfuno zesicelo.

Ziziphi iimpawu eziqhelekileyo zevalvu yokumelana ne-counterbalance engasebenzi kakuhle?

Iimpawu eziqhelekileyo ziquka ukushukuma komthwalo, ukuxokozela, okanye ukungazinzi. Ukuvuza kwangaphandle kunye nokushisa kakhulu kubonisa iingxaki ezinokubakho. Ukuxilongwa ngokukhawuleza kuthintela umonakalo ongakumbi kwinkqubo. ⚠️