Industrial B2B operations critically require high-precision LPS pressure switch upgrades in 2025. This necessity drives significant technological adoption. These advancements effectively address escalating demands for operational efficiency, enhanced safety, and robust data-driven decision-making processes. Consequently, strategic investment in advanced LPS pressure switch technology provides a crucial competitive advantage for businesses.

Industrial B2B operations critically require high-precision LPS pressure switch upgrades in 2025. This necessity drives significant technological adoption. These advancements effectively address escalating demands for operational efficiency, enhanced safety, and robust data-driven decision-making processes. Consequently, strategic investment in advanced LPS pressure switch technology provides a crucial competitive advantage for businesses.

Key Takeaways

- Upgrading LPS pressure switches makes factories work better. It helps them run smoothly and saves money.

- New pressure switches make workplaces safer. They help follow important safety rules.

- These upgrades use data to make smart choices. This helps businesses stay ahead of others.

The Evolving Landscape: Why High-Precision LPS Pressure Switch Technology is Critical

Current Limitations of Traditional LPS Pressure Switches

Traditional mechanical LPS pressure switches often present limitations in modern industrial settings. These devices offer less precision compared to newer technologies. They typically require regular calibration to maintain accuracy over time. While traditional switches are durable and have lower initial costs, their operational costs can increase due to less precise control. This can lead to inefficiencies or missed early warnings of system issues. Businesses find these older switches less effective where exact measurements are critical for process control and safety.

The Imperative for High-Precision LPS Pressure Switch Monitoring in Industry 4.0

High-precision LPS pressure switch monitoring is essential for Industry 4.0 and smart factories. These advanced electronic sensors continuously monitor equipment pressure. This continuous data stream acts as the backbone for effective monitoring systems. They enable early detection of pressure drops, which can signal blockages, or pressure spikes, which might indicate potential breakages. The data collected from these sensors helps create models that predict equipment degradation. This predictive capability allows for “just-in-time” maintenance, ensuring servicing only when necessary. High-precision instruments remove guesswork, providing accurate trend data for proactive planning. They integrate easily into smart factory systems, sending real-time information for better decision-making.

Key Technological Advancements in LPS Pressure Switch Design

Enhanced Accuracy and Repeatability in LPS Pressure Switches

Modern LPS pressure switch designs offer significantly improved accuracy. They provide consistent readings over time. This repeatability ensures reliable process control. Engineers design these switches with advanced sensing elements. These elements reduce measurement errors. Industrial operations benefit from precise pressure monitoring. This precision helps maintain optimal system performance.

Digital Integration and Smart Capabilities for LPS Pressure Switches

Digital integration transforms LPS pressure switches into smart devices. These switches offer remote monitoring and control. For example, some digital dial gauges transmit data via WIKA Wireless. Users connect to iOS or Android apps. They modify settings and collect data through these apps. This data transfers to a PC for further analysis. These devices also log data internally. They send digital signals to computers or monitoring systems. This allows for recording, saving, and analyzing pressure data.

Robustness and Durability of LPS Pressure Switches for Harsh Environments

Modern LPS pressure switches are built for harsh industrial environments. Manufacturers select specific materials for durability.

| Category | Material/Feature | Contribution to Durability |

|---|---|---|

| Diaphragms & Seals | Viton (FKM) | Resists petroleum fluids, solvents, and aggressive chemicals; high heat resistance. |

| PTFE (Teflon) | Withstands extreme high temperatures, aggressive chemicals, and abrasive slurries. | |

| Nitrile (NBR/Buna-N) | Resists oils and petroleum-based fluids; suitable for general industrial use. | |

| EPDM | Resists high-temperature water, steam, ozone, and mild acids. | |

| Wetted Parts | Stainless steel, Monel, Hastelloy | Chosen for corrosion resistance, high strength, and long-term durability. |

| Switch Housing | IP, NEMA, ATEX rated enclosures | Protects against dust, water, and explosive atmospheres. |

| Contacts & Terminals | Copper, Silver, Gold | Offers high corrosion resistance and electrical conductivity. |

| Pressure-Sensing Elements | Metal diaphragms, Precision pistons | Withstand high pressures; provide rapid response. |

These materials and features ensure reliable operation. They protect against corrosion, vibration, and extreme temperatures.

Advanced Diagnostics and Self-Monitoring Features in Modern LPS Pressure Switches

Advanced LPS pressure switches include diagnostic and self-monitoring features. They detect internal faults or performance deviations. These switches alert operators to potential issues. This reduces the need for manual inspections. Predictive maintenance becomes easier. These features enhance operational reliability and minimize unexpected downtime.

Tangible Benefits and ROI of Upgrading Your LPS Pressure Switch Systems

Upgrading to advanced LPS pressure switch systems offers significant returns on investment for industrial B2B operations. These upgrades translate directly into improved performance, enhanced safety, and substantial cost savings. Businesses gain a competitive edge through these strategic investments.

Maximizing Operational Efficiency and Throughput with Upgraded LPS Pressure Switches

Upgraded LPS pressure switches significantly boost operational efficiency. They provide precise control over industrial processes. This precision minimizes waste and optimizes resource utilization. For example, in pumping systems, these switches prevent dry running. This protects pumps from damage and extends their operational life. They also safeguard membranes from low water supply conditions. This optimization of pump and membrane performance directly reduces energy consumption. Operating a pump only when necessary prevents excessive power consumption and inefficiency. Unnecessary pump usage overworks components. This makes them less effective and often requires frequent repairs or replacements. All these factors contribute to higher energy costs. Advanced LPS pressure switches ensure equipment runs only when needed, leading to substantial energy savings and increased throughput.

Elevating Safety Standards and Compliance with High-Precision LPS Pressure Switches

High-precision LPS pressure switches play a critical role in elevating safety standards. They ensure compliance with stringent industry regulations. Many industrial applications require specific safety integrity levels (SIL). These levels classify a system’s reliability in performing its safety function.

| Safety Integrity Level (SIL) | Risk Level | Requirements/Consequences of Failure |

|---|---|---|

| SIL 1 | Low | Basic safety requirements |

| SIL 2 | Moderate | May require redundancy in alarming and testing |

| SIL 3 | High | Failure could lead to injury or equipment damage; often requires redundant safety design and fault annunciation |

| SIL 4 | Extremely High | Requires additional safety considerations to reduce risk; intended to prevent catastrophic failures |

High-precision LPS pressure switches, especially those that are SIL-certified, meet the IEC 61508 standard for functional safety in high-risk applications. This certification applies to individual field devices like pressure switch sensors. These sensors often serve as critical safety shutdown mechanisms. Approximately 50% of switch applications in industrial settings require safety shutdowns. SIL-certified instruments are essential in systems where a single failure could lead to serious consequences. They protect people, equipment, and the environment. For instance, Ashcroft’s A-Series and B-Series Pressure Switches are SIL 3 capable. Manufacturers build them with specific construction criteria to meet these stringent requirements for safety-critical applications.

Reducing Maintenance Costs and Downtime Through Advanced LPS Pressure Switches

Advanced LPS pressure switches significantly reduce maintenance costs and minimize downtime. Their self-monitoring and diagnostic features detect potential issues early. This allows for proactive maintenance scheduling. Businesses avoid unexpected equipment failures. Predictive maintenance strategies replace reactive repairs. This extends the lifespan of machinery. It also reduces the frequency of costly emergency repairs. The robust design of modern LPS pressure switches also contributes to their longevity. They withstand harsh operating conditions. This durability means fewer replacements and less labor for maintenance.

Enabling Data-Driven Decision Making with Integrated LPS Pressure Switch Data

Integrated LPS pressure switch data empowers businesses to make informed decisions. These advanced switches collect real-time pressure information. They transmit this data to central monitoring systems. Engineers analyze trends and identify patterns. This data helps optimize processes, troubleshoot problems, and improve overall system performance. For example, historical pressure data can reveal inefficiencies or predict equipment wear. This allows managers to adjust operations or schedule maintenance precisely. Data-driven insights lead to more efficient resource allocation and better strategic planning.

Hanshang Hydraulic’s Commitment to Advanced LPS Pressure Switch Solutions

Pioneering Innovation in LPS Pressure Switch Design and Manufacturing

Hanshang Hydraulic leads innovation in pressure switch technology. Their dedicated R&D team uses advanced 3D design software like PROE and Solidcam. This ensures efficient and accurate product development. For example, the LPS-01 series piston pressure switches use micro-switches to control hydraulic components. These switches offer a large pressure control range, making them easy to operate and install. Hanshang also launched a new LPS pressure switch for automotive assembly lines. This switch provides unparalleled precision. It holds CE certification, guaranteeing reliability and safety in critical manufacturing processes. This advanced solution elevates monitoring standards and operational efficiency.

Precision Engineering and Quality Assurance for LPS Pressure Switches

Hanshang Hydraulic commits to precision engineering and quality assurance. They operate a 12,000 square meter facility, including a 10,000 square meter standard workshop. This facility houses over a hundred machines, such as CNC lathes and high-precision grinders. Hanshang developed a hydraulic valve test bench. This bench tests pressures up to 35MPa and flows up to 300L/Min. It precisely measures dynamic, static, and fatigue performance. The company holds ISO9001-2015 quality management certification. Their full range of hydraulic valves for export also has CE certification. Hanshang ensures stable and reliable hydraulic products for customers. They also implemented automated warehousing and WMS/WCS systems, earning a “digital workshop” rating in 2022.

Global Reach and Reliability of Hanshang Hydraulic LPS Pressure Switches

Hanshang Hydraulic’s products enjoy a high market reputation. Their industrial hydraulic valves, mobile machinery hydraulic valves, and screw-in cartridge valves sell well across China. They also export to over 30 countries and regions, including Europe. Hanshang Hydraulic aims to become a renowned brand in the hydraulic field. They invite partners to collaborate and achieve shared success.

Practical Applications of High-Precision LPS Pressure Switches Across Industries

Oil & Gas: Enhanced Safety and Process Control with LPS Pressure Switches

High-precision LPS pressure switches significantly enhance safety in oil and gas operations. They provide interlock protection through a ‘window’ capability. Operators set high and low pressure limits. If pressure falls outside this safe range, a relay de-energizes. This action shuts down operations. The interlock ties directly to the main power panel. This forces operators to physically inspect the well site before restarting. It prevents remote restarts in unsafe conditions. The system only allows well operation within the established safe pressure zone. These switches integrate into the control system. They act as a cutoff for the main panel power. This ensures continuous protection. They also feature failsafe capabilities. They default to a ‘normally open’ state upon power loss. This automatically engages the interlock. It shuts down the pump. This prevents operation in potentially hazardous situations.

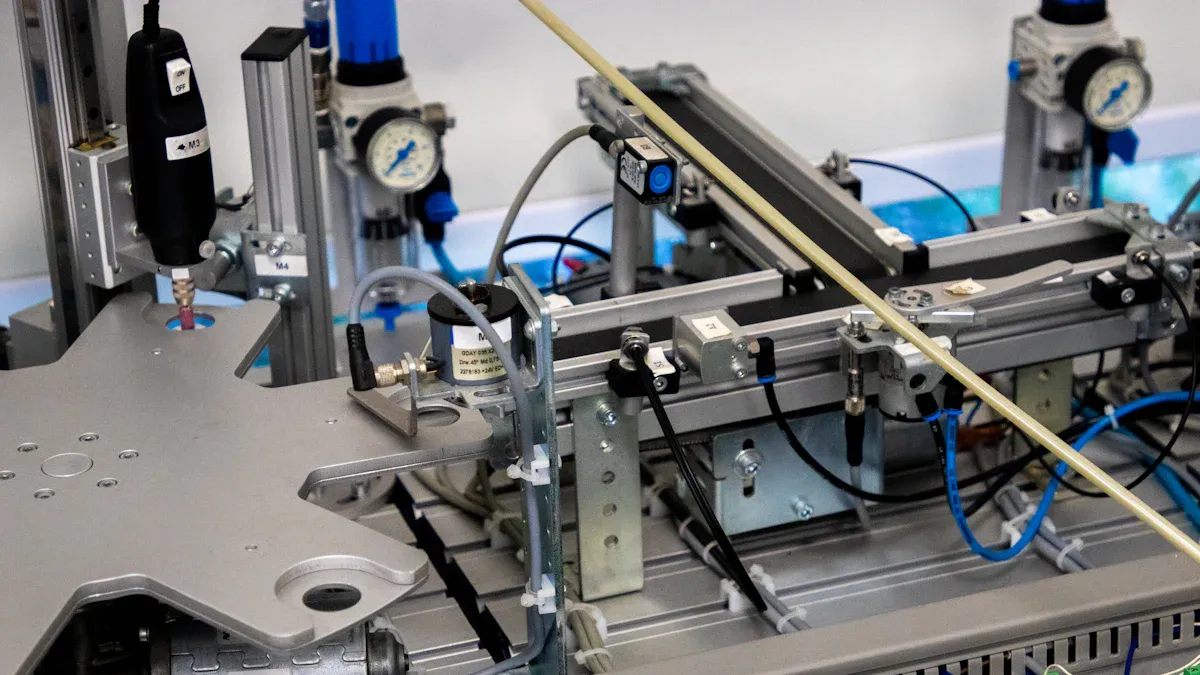

Manufacturing: Precision Automation with LPS Pressure Switches in Robotics and Assembly

In manufacturing, high-precision LPS pressure switches enable precise automation. They are crucial for robotics and assembly lines. These switches monitor pneumatic and hydraulic systems with extreme accuracy. This ensures consistent force and movement in robotic arms. They prevent damage to delicate components during assembly. Their reliable feedback helps maintain tight tolerances. This leads to higher product quality and reduced waste.

Chemical Processing: Critical Monitoring for Hazardous Environments with LPS Pressure Switches

Chemical processing plants rely on critical monitoring for hazardous environments. High-precision LPS pressure switches provide this essential function. They monitor pressure in reactors, pipelines, and storage tanks. This prevents dangerous over-pressurization or vacuum conditions. Their robust design withstands corrosive chemicals and extreme temperatures. This ensures safe operation and prevents leaks of hazardous substances.

Water/Wastewater Treatment: Optimized Pumping and Filtration Using LPS Pressure Switches

LPS pressure switches optimize pumping and filtration in water treatment plants. They are crucial in RO automation. They monitor and control the safety interlock of high-pressure pumps in Reverse Osmosis (RO) systems. These switches effectively track and monitor micron filter performance. This ensures smooth operation of filtration systems. They protect high-pressure pumps and RO membranes. This ensures the safety and efficiency of filtration systems. They offer precise pressure control with customizable set points. Fixed hysteresis provides stable and reliable performance.

Investing in high-precision LPS pressure switch upgrades is a strategic imperative for industrial B2B operations in 2025. These upgrades drive unparalleled efficiency, bolster safety, and provide a competitive edge. Future-proof your industrial processes with advanced LPS pressure switch technology for long-term operational excellence.

FAQ

What benefits do upgraded LPS pressure switches offer?

Upgraded LPS pressure switches maximize operational efficiency. They elevate safety standards and reduce maintenance costs. They also enable data-driven decision-making for industrial processes.

How do LPS pressure switches contribute to Industry 4.0?

High-precision LPS pressure switches provide continuous monitoring. They generate real-time data for predictive maintenance. These switches integrate into smart factory systems, supporting advanced automation and control.

What ensures the quality of Hanshang Hydraulic’s LPS pressure switches?

Hanshang Hydraulic uses precision engineering and advanced testing. They hold ISO9001-2015 and CE certifications. This commitment ensures stable, reliable, and high-quality LPS pressure switch products.