A valve block is a compact, integrated manifold efficiently managing hydraulic fluid flow, pressure, and direction. This unit consolidates multiple hydraulic functions, centralizing control for various components. What is a valve block primarily manages fluid flow and pressure, acting as the central nervous system. The global hydraulic valve block market, valued at USD 3.4 billion in 2023, projects significant growth to USD 5.6 billion by 2032.

A valve block is a compact, integrated manifold efficiently managing hydraulic fluid flow, pressure, and direction. This unit consolidates multiple hydraulic functions, centralizing control for various components. What is a valve block primarily manages fluid flow and pressure, acting as the central nervous system. The global hydraulic valve block market, valued at USD 3.4 billion in 2023, projects significant growth to USD 5.6 billion by 2032.

Key Takeaways

- A valve block is a compact unit. It controls how hydraulic fluid moves, its pressure, and its direction. It combines many hydraulic parts into one place.

- Valve blocks make hydraulic systems better. They save space and stop leaks. They also make it easier to fix problems.

- Valve blocks are used in many industries. These include factories, construction, and farming. They help machines work precisely and safely.

What Is a Valve Block and How Does It Function?

A valve block is a compact, integrated manifold designed to efficiently manage hydraulic fluid flow, pressure, and direction within a hydraulic system. Understanding what is a valve block involves examining its core functions and how it integrates various components. This section explores the fundamental ways a valve block operates within a hydraulic system.

Directing Hydraulic Fluid Flow

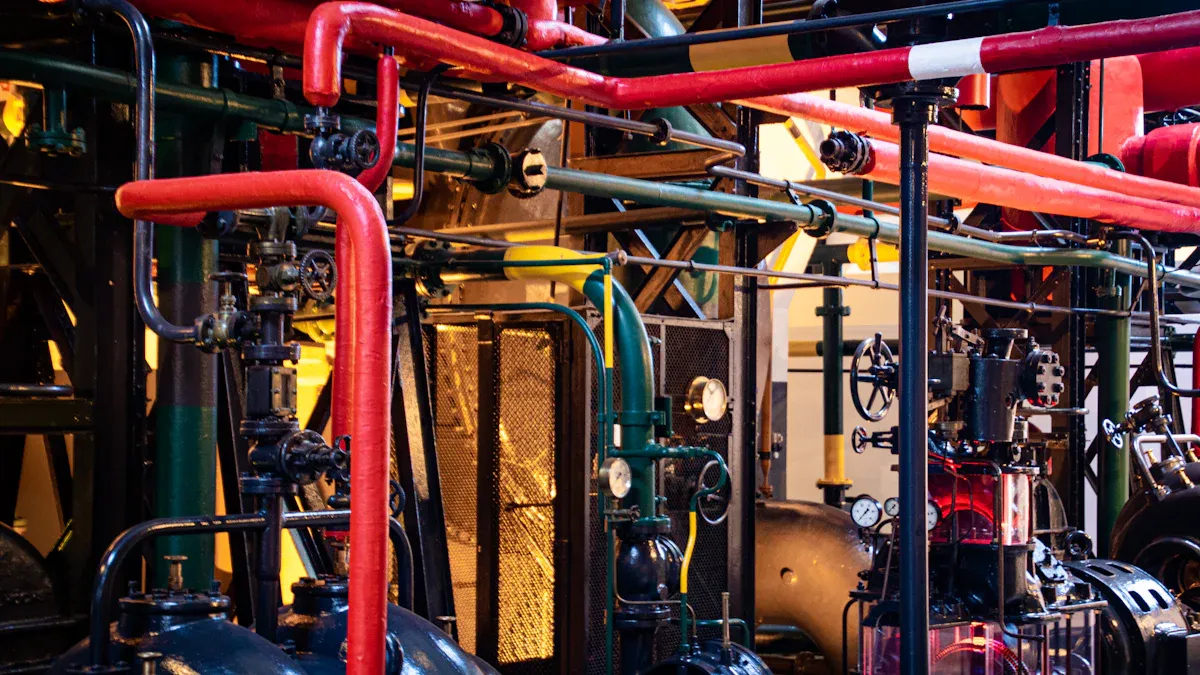

A valve block body forms the central component. It acts as a structural support and contains the network of channels for oil flow. Manufacturers typically construct these bodies from aluminum or malleable cast iron. This body serves as the mounting platform for other hydraulic components. These include hydraulic valves, such as plate, cartridge, or superimposed valves. Workers mount these valves onto the block using screws. Pipe joints connect external piping to the valve block. These joints facilitate oil flow to and from actuators. They also manage oil input, return, and drainage. Other accessories, like pipeline connection flanges, plugs for process holes, and sealing rings, complete the assembly. This comprehensive integration defines what is a valve block in terms of its physical structure.

Valve blocks direct hydraulic fluid flow using various valve types.

- Block valves isolate sections of a pipeline or control fluid flow into or out of the system. They perform a straightforward function of blocking or allowing flow.

- Bleed valves release controlled pressure or vent. They prevent over-pressurization.

- Multi-valve manifolds suit systems needing many control points in a small space.

- Other common valves include ball valves for general on/off control and globe valves for precise flow control. Check valves prevent backflow. Solenoid valves allow for automated control.

Regulating Hydraulic Pressure

Valve blocks regulate hydraulic system pressure through various mechanisms. Pressure control valves (PCVs) are key components. They limit or reduce fluid pressure in a hydraulic circuit. A pressure reducing valve maintains a specific pressure level. It closes when a preset maximum downstream pressure is reached. Relief valves drain excess pressurized fluid back to the reservoir. They activate once a predetermined system pressure is met. These valves are often placed after the hydraulic pump. Sequence valves divert fluid from one circuit branch to another. This happens after a critical pressure is achieved. Pilot-operated reducing valves and pilot-operated relief valves offer more sophisticated control. These valves prevent leakage and avoid issues like burst pipes. The precise control over pressure is a fundamental aspect of what is a valve block.

Controlling Actuator Movement

Valve blocks precisely control the movement of hydraulic actuators. They manage the start, stop, and direction of movement. They also regulate the speed and output force or torque of an actuator. This control happens by changing the valve area. The spool and valve body move relative to each other. This action regulates and controls the fluid. Directional control valves are crucial for this function. They receive external signals and adjust fluid pathways. This allows for accurate and responsive control of hydraulic cylinders and motors.

Ensuring System Safety and Stability

Valve blocks incorporate several safety features. These features ensure system safety and stability. They prevent accidental movement. These valves block fluid flow when not engaged. This stops hydraulic actuators from unexpected movement. This is critical for load-bearing equipment. Lock valves hold the load securely during system failures. This reduces accident risks from sudden system failures. This includes electrical signal loss or hydraulic pressure loss. Control reliability is a key design principle. A single component failure does not prevent normal machine stopping. It prevents subsequent cycles until the failure is corrected. Redundant valving elements and monitoring ensure safety. If one element malfunctions, the safety PLC commands the valve to a safe condition.

Specific safety standards and certifications apply to hydraulic valve blocks.

- ISO 4401 defines mounting interface dimensions. This ensures interchangeability and compatibility.

- CE Certification indicates compliance with EU mechanical safety. It allows circulation within the EU market.

- SIL (Safety Integrity Level) certification involves risk analysis and functional testing. It ensures a device can prevent or mitigate accidents effectively.

Advantages and Design Considerations of a Valve Block

Valve blocks offer significant benefits in hydraulic systems. Their design principles focus on efficiency and reliability. These advantages make them a preferred choice in many industrial applications.

Space Efficiency and Compactness

Valve blocks significantly enhance space efficiency. Designers balance size and performance in compact hydraulic system design. They optimize oil circuit layouts to minimize pressure loss. Strategic passage routing enhances efficiency in integrated valve systems. This thoughtful design contributes to a more compact unit. System integration and function matching ensure the oil circuit aligns with the hydraulic system’s schematic. This integrates circuits for simplification and compactness. Component layout and installation also play a role. Manufacturers arrange hydraulic components with minimum spacing. They strategically extend components like pilot valves outside the installation plane. This reduces overall size.

Reduced Leakage Points

Valve blocks drastically reduce potential leakage points. Integrated manifolds can eliminate approximately 85% of potential leak points. Double block and bleed (DBB) blocks reduce leak points by around 98% in some applications. Modern valve blocks replace complex assemblies. They decrease tubing connections by 80-90%. This significantly reduces leak opportunities. A 50% reduction in potential leak points is achievable. This meets ISO 4413:2024 standards.

Simplified Maintenance and Troubleshooting

Valve blocks simplify maintenance and troubleshooting. They consolidate many components into one unit. This makes inspection and repair easier. Technicians can develop preventative maintenance schedules. These schedules are tailored to system needs. They consider factors like pressure and temperature. Periodically verifying valve operation helps detect issues. Leaks often indicate improper operation. Diagnostic tools like the CCC Valve Exerciser verify valve health. They use partial-stroke tests without disturbing the process. This helps identify emerging problems.

Customization and Integration Capabilities

Manufacturers integrate specialized functions into custom valve block designs. They understand application requirements. This includes fluid type, temperature, and pressure. They recommend suitable base valve types and materials. Advanced CAD software creates precise 3D models. This allows for Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD). This optimizes flow efficiency. Valve blocks can be customized for reliable pathway connections. They accommodate various valve types. This includes plate valves, two-way cartridge valves, or threaded cartridge valves.

Common Valve Block Types

Common valve block types include monoblock and modular designs. Each offers distinct characteristics.

| Feature | Monoblock | Modular |

|---|---|---|

| Space Efficiency | Excellent for compact, fixed designs | Very good, reduces external piping |

| Installation Ease | Very easy, fewer connections | Easy, modules mount onto manifold |

| Footprint | Smallest for basic functions | Often compact due to reduced plumbing |

| Layout Flexibility | Limited, fixed shape | High, manifold design offers many options |

Monoblock designs offer high pressure tolerance and durability. They are difficult to modify post-production. Modular stackable blocks are scalable. They are easy to service or reconfigure. They support multi-function circuits. However, they have more potential leak paths between modules. Understanding what is a valve block involves recognizing these design variations.

Industrial Applications for Hydraulic Systems Using Valve Blocks

Hydraulic valve blocks play a crucial role across diverse industrial sectors. They provide precise control and robust performance.

Manufacturing and Automation

Valve blocks are essential in manufacturing and automation. They appear in lathe machines, machining centers, and automated material supply systems. Intelligent valves, with high-quality sensors and control systems, enable precise control. They also allow for condition monitoring and predictive maintenance. Advanced digital valves facilitate remote status monitoring. This leads to refined management of the manufacturing process. Solenoid valves receive signals remotely to control actuators. This contributes to efficient operation. High-speed manufacturing processes for solenoid valve blocks require precise assembly and rapid response testing.

Construction and Heavy Equipment

Construction and heavy equipment widely use hydraulic valve blocks. These include all hydraulic motors, final drive motors, and travel motors. Excavator hydraulic main control valve blocks, John Deere Combines, and truck hook arm valve blocks also use them. Quick coupler valve blocks enhance robust performance. They enable fast attachment changes on construction machinery. Their optimized design eliminates pilot circuit noise. They undergo extensive durability testing, ensuring high performance. Valve blocks protect hydraulic components by venting excess fluid. This keeps system pressure within safe limits.

Agriculture and Forestry

Hydraulic power integrates into almost every type of agricultural machinery. This includes equipment moving heavy loads and hydraulic circuits supporting header accumulator systems on combines. Hydraulic cylinder valve blocks are crucial components in modern hydraulic control systems. They enhance fluid control, decrease system complexity, and boost efficiency. In forestry, valve blocks reduce pressure losses. This ensures more wheel power is available. They also offer a wider operating range and optimized flow behavior. Integrated components like pressure compensators and make-up valves contribute to energy savings.

Marine and Offshore Systems

Offshore drilling platforms utilize marine hydraulic systems. These systems incorporate hydraulic valve blocks. Marine steering systems, winches, propellers, and cargo handling systems also use them. Valve blocks ensure reliability in harsh marine environments. Components often use corrosion-resistant alloys. Robust designs withstand vibration and extreme temperatures. Advanced control systems incorporate embedded controllers and sensors. This allows for precise operation and real-time monitoring. Integration with ship management systems provides centralized control and diagnostics.

Energy and Power Generation

Hydropower plants, solar power, and wind power systems employ hydraulic valve blocks. Geothermal and aquathermal power also use them. Hydraulic valve blocks are integral to electro-hydraulic steam valve actuation systems. These systems are in turbines within electrical power stations. Valve blocks contain internal valves that manage energy within an accumulator. A locking ball valve allows technicians to drain the accumulator safely. A second ball valve blocks incoming pump fluid, adding an extra layer of safety.

Valve blocks are indispensable components in modern hydraulic systems. They offer precise control, enhanced efficiency, and robust performance across many industrial sectors. Their ability to consolidate functions improves system reliability. This makes them critical for advanced hydraulic applications. The continued evolution of what is a valve block technology will further optimize hydraulic system design and functionality.

FAQ

What is the primary purpose of a valve block?

A valve block efficiently manages hydraulic fluid flow, pressure, and direction. It consolidates multiple hydraulic functions into a single, compact unit.

How do valve blocks improve hydraulic system efficiency?

Valve blocks enhance efficiency by reducing leakage points and saving space. They simplify maintenance and integrate various functions into one unit.

Can valve blocks be customized for specific applications?

Yes, manufacturers design custom valve blocks. They integrate specialized functions based on application requirements. This includes fluid type, temperature, and pressure.