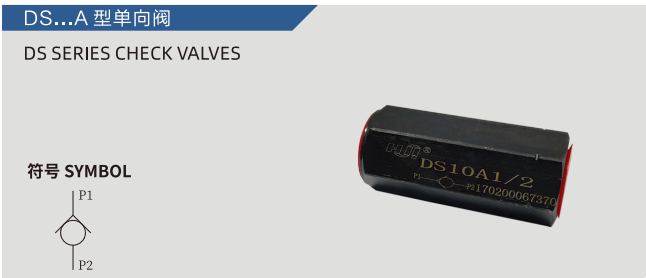

Hanshang Hydraulic’s DS Series HYDRAULIC CHECK VALVES, specifically the DS…A model, unlock superior system performance. These essential CHECK VALVES maintain precise directional flow control. They offer unparalleled advantages, optimizing hydraulic operations with robust design and reliable function for various demanding applications.

Key Takeaways

- DS Series valves stop fluid from flowing backward. This protects your hydraulic system parts from damage.

- These valves make your hydraulic system work better. They use less energy and keep the fluid moving smoothly.

- DS Series valves help your equipment last longer. They reduce wear and tear and clean themselves.

Unwavering System Reliability with DS Series HYDRAULIC CHECK VALVES

Superior Backflow Prevention in HYDRAULIC CHECK VALVES

Hanshang Hydraulic‘s DS Series excels at preventing backflow. These valves ensure fluid moves in only one direction. This critical function protects sensitive components from damage. Reverse flow can cause significant operational issues. The DS Series’ precision engineering guarantees a positive shut-off. This capability maintains system integrity. Operators experience consistent and predictable performance. The design minimizes pressure surges caused by sudden flow reversals. This contributes to a more stable hydraulic circuit. It safeguards pumps, actuators, and other vital equipment from potential harm. This superior backflow control is fundamental for maintaining system health and preventing costly downtime. It also prevents contamination from flowing backward into clean areas, further enhancing system longevity.

Robust Construction for Durable HYDRAULIC CHECK VALVES

The DS Series HYDRAULIC CHECK VALVES feature robust construction. Hanshang Hydraulic uses high-quality materials. This ensures exceptional durability in harsh industrial settings. Each valve undergoes meticulous manufacturing processes. This commitment to quality results in a long service life. The sturdy design resists wear and tear. It withstands high pressures and continuous operation. This robust build minimizes maintenance needs. It also reduces the risk of unexpected failures. Systems equipped with DS Series valves operate reliably for extended periods. This provides peace of mind for system operators. Their solid build quality ensures consistent performance even under demanding conditions, making them a dependable choice for critical applications. This robust design also contributes to reduced vibration and noise, creating a more stable operating environment.

Enhanced Operational Efficiency of DS Series HYDRAULIC CHECK VALVES

Low Cracking Pressure in HYDRAULIC CHECK VALVES

Hanshang Hydraulic‘s DS Series valves feature low cracking pressure. This means the valve opens with minimal force. It requires less energy from the hydraulic system. This directly translates to improved operational efficiency. Systems experience reduced pressure drop across the valve. This preserves system pressure for critical tasks. Lower cracking pressure also minimizes heat generation. It contributes to cooler operating temperatures. This design choice ensures the system operates smoothly. It also reduces overall energy consumption. Operators benefit from more responsive and efficient hydraulic circuits.

Optimized Flow Path Design for HYDRAULIC CHECK VALVES

The DS Series incorporates an optimized flow path design. Engineers meticulously shaped the internal passages. This design minimizes turbulence within the valve. It reduces resistance to fluid flow. Smooth fluid movement prevents unnecessary energy loss. This design also helps maintain consistent system pressure. It reduces the risk of cavitation. The optimized path ensures maximum flow capacity. It does so with minimal pressure drop. This efficiency extends to the entire hydraulic system. It contributes to longer component life. The design ensures reliable and consistent performance.

Extended Equipment Lifespan with DS Series HYDRAULIC CHECK VALVES

Damping Options for HYDRAULIC CHECK VALVES

Hanshang Hydraulic‘s DS Series offers crucial damping options. These features significantly reduce shock and vibration within hydraulic systems. They protect sensitive components from premature wear and fatigue. Damping effectively prevents the damaging effects of water hammer. This extends the operational life of pipes, fittings, and other system elements. It also contributes to a quieter operating environment. Operators observe smoother system performance. This proactive protection minimizes stress on the entire hydraulic circuit, ensuring long-term reliability and reducing the frequency of component replacement.

Self-Cleaning Design of HYDRAULIC CHECK VALVES

The DS Series incorporates an innovative self-cleaning design. This mechanism actively prevents the accumulation of particles and debris inside the valve. Contaminants often cause blockages and accelerate wear in conventional valves. The self-cleaning action ensures consistent valve operation and maintains optimal flow characteristics. It significantly reduces the need for manual cleaning and associated maintenance downtime. This design choice directly contributes to the extended lifespan of the valve itself. It also helps maintain the overall efficiency and longevity of the entire hydraulic system.

Versatility and Seamless Integration of DS Series HYDRAULIC CHECK VALVES

Hanshang Hydraulic designs the DS Series for broad application. These valves offer exceptional adaptability. They integrate smoothly into diverse hydraulic systems. This versatility makes them a preferred choice for many industries. Their design philosophy centers on universal applicability. This ensures engineers can confidently specify them for new projects or existing system upgrades.

Wide Range of Sizes and Pressure Ratings for HYDRAULIC CHECK VALVES

Hanshang Hydraulic provides the DS Series in numerous sizes. They also offer various pressure ratings. This extensive selection meets specific system demands. Engineers find suitable valves for small circuits or large industrial machinery. This wide range ensures optimal performance across different operating conditions. It simplifies system design and component selection. Customers can precisely match valve specifications to their exact needs. This eliminates the need for custom solutions. This broad offering supports a vast array of hydraulic applications.

Multiple Connection Options for HYDRAULIC CHECK VALVES

The DS Series offers multiple connection options. These include threaded, flanged, and subplate mounting. This variety ensures compatibility with existing infrastructure. It also allows for flexible new installations. Operators can choose the best fit for their system layout. This simplifies installation processes. It reduces overall setup time and costs. The diverse options enhance system modularity. This makes system upgrades and maintenance more straightforward. The DS Series HYDRAULIC CHECK VALVES truly offer seamless integration. This adaptability minimizes engineering challenges. It maximizes operational flexibility for users.

Advanced Safety Features of DS Series HYDRAULIC CHECK VALVES

Positive Shut-Off Capability in HYDRAULIC CHECK VALVES

Hanshang Hydraulic‘s DS Series valves deliver positive shut-off. This critical capability ensures complete fluid containment. It prevents any unintended bypass or leakage within the system. Precision manufacturing and advanced sealing technologies guarantee a consistently tight seal. A spring-loaded poppet mechanism ensures rapid and decisive closure. This feature safeguards hydraulic systems from reverse flow damage. It protects sensitive components like pumps and actuators. Positive shut-off also significantly enhances operational safety. It prevents accidental fluid discharge, protecting personnel and the environment. Operators rely on this dependable function for predictable system behavior. This robust design maintains system integrity during critical operations. It also prevents contamination from entering clean sections of the circuit.

Pressure Surge Protection by HYDRAULIC CHECK VALVES

The DS Series provides robust protection against pressure surges. Sudden, intense pressure spikes can severely damage hydraulic components. These valves effectively absorb and dissipate such surges. They prevent the destructive effects of water hammer. The valve’s controlled closing speed helps mitigate pressure transients. This protection extends the operational lifespan of pipes, fittings, and other system elements. It also safeguards expensive pumps and actuators from premature wear. The design minimizes stress on the entire hydraulic circuit. This contributes to a safer working environment. It reduces the risk of catastrophic failures. The DS Series ensures stable and reliable system operation, even under dynamic conditions. It protects downstream equipment from sudden pressure changes.

Cost-Effectiveness of DS Series HYDRAULIC CHECK VALVES

Minimized Wear and Tear with HYDRAULIC CHECK VALVES

The DS Series significantly reduces wear and tear across the entire hydraulic system. Its precise flow control prevents damaging pressure spikes and cavitation, which often degrade other components prematurely. This protection extends the operational life of pumps, cylinders, and other expensive parts within the circuit. Operators experience fewer unexpected breakdowns and less need for frequent repairs, saving valuable time and resources. The smooth, controlled operation of these valves, coupled with their effective damping options, minimizes stress on connections, hoses, and seals. This proactive approach to system health directly lowers overall maintenance expenses. It also ensures consistent and reliable performance, reducing costly downtime and improving overall productivity.

Long-Term Durability of HYDRAULIC CHECK VALVES

Hanshang Hydraulic engineers the DS Series for exceptional long-term durability. They use high-grade materials and advanced manufacturing techniques, ensuring each valve meets stringent quality standards. This robust construction allows the valves to withstand harsh operating conditions, including high pressures, extreme temperatures, and corrosive fluids. They resist corrosion and abrasion effectively, maintaining their integrity and function over time without compromise. The innovative self-cleaning design further contributes to their longevity by actively preventing internal debris accumulation and blockages. This extended lifespan means fewer valve replacements, which translates into significant savings on parts and labor costs. Businesses benefit from reliable service for many years. This consistent performance contributes to a remarkably lower total cost of ownership, making the DS Series a smart and economical investment for any demanding hydraulic application.

Hanshang Hydraulic’s DS Series valves transform hydraulic system performance. They offer superior reliability, enhanced efficiency, and extended equipment lifespan. Investing in these advanced HYDRAULIC CHECK VALVES ensures long-term operational success. The DS Series future-proofs operations, providing dependable and cost-effective fluid control.

FAQ

What is the primary function of a DS Series HYDRAULIC CHECK VALVE?

A DS Series HYDRAULIC CHECK VALVE primarily ensures one-way fluid flow. It prevents backflow, protecting hydraulic components from damage. This maintains system integrity and operational safety.

How do DS Series valves enhance system efficiency?

DS Series valves feature low cracking pressure and optimized flow paths. This design minimizes energy loss and pressure drop. It leads to reduced power consumption and improved overall system performance.

Can DS Series valves extend equipment lifespan?

Yes, DS Series valves extend equipment lifespan. They offer damping options to reduce shock and vibration. Their self-cleaning design prevents debris accumulation, minimizing wear and tear on components.