MODULAR DIRECTIONAL VALVE ELEMENTS MWE6: significantly boost hydraulic system efficiency for industrial machinery manufacturers. These elements offer precise control, reduced energy consumption, and simplified integration. This directly addresses the need for optimized machine performance, lower operating costs, and streamlined design and maintenance processes. Hanshang Hydraulic emphasizes innovation and excellence through these advanced components.

MODULAR DIRECTIONAL VALVE ELEMENTS MWE6: significantly boost hydraulic system efficiency for industrial machinery manufacturers. These elements offer precise control, reduced energy consumption, and simplified integration. This directly addresses the need for optimized machine performance, lower operating costs, and streamlined design and maintenance processes. Hanshang Hydraulic emphasizes innovation and excellence through these advanced components.

Key Takeaways

- MWE6 valves help machines use less energy. This saves money and makes machines run cooler.

- MWE6 valves make machines work better and more accurately. This helps factories make higher quality products.

- MWE6 valves are easy to put into machines. They also make repairs simpler and faster.

The Efficiency Challenge in Industrial Hydraulics

Current Hurdles: Energy Waste, Complex Designs, and Maintenance Downtime

Current Hurdles: Energy Waste, Complex Designs, and Maintenance Downtime

Industrial hydraulic systems face significant challenges. Energy waste is a primary concern. For example, a pump operating at 80% efficiency with a 10-horsepower input generates 2 horsepower of heat. This heat must then be removed from the system. Several factors contribute to this energy loss. Inadequate fluid flow, often caused by clogged filters or undersized hoses, prevents proper energy transfer. Excessive pressure drops, resulting from worn valves or sharp pipe bends, also convert hydraulic energy into heat. Contaminated or incorrect fluid increases friction and reduces heat dissipation. Furthermore, faulty heat exchangers or oversized components generate more heat, reducing overall system efficiency. Frictional losses and turbulent flow also convert kinetic energy into heat, leading to pressure drops. These inefficiencies complicate system designs and increase maintenance downtime.

The Manufacturer’s Imperative: Performance, Reliability, and Cost-Effectiveness

Industrial machinery manufacturers prioritize several key performance metrics for hydraulic systems. They aim for high energy efficiency, reduced fluid waste, and improved positioning accuracy. Manufacturers seek to optimize components like pumps and valves to lower overall energy consumption. They also focus on minimizing leaks through high-quality seals and robust connections. Achieving a balance between flow and velocity is crucial for quick response times without compromising system stability.

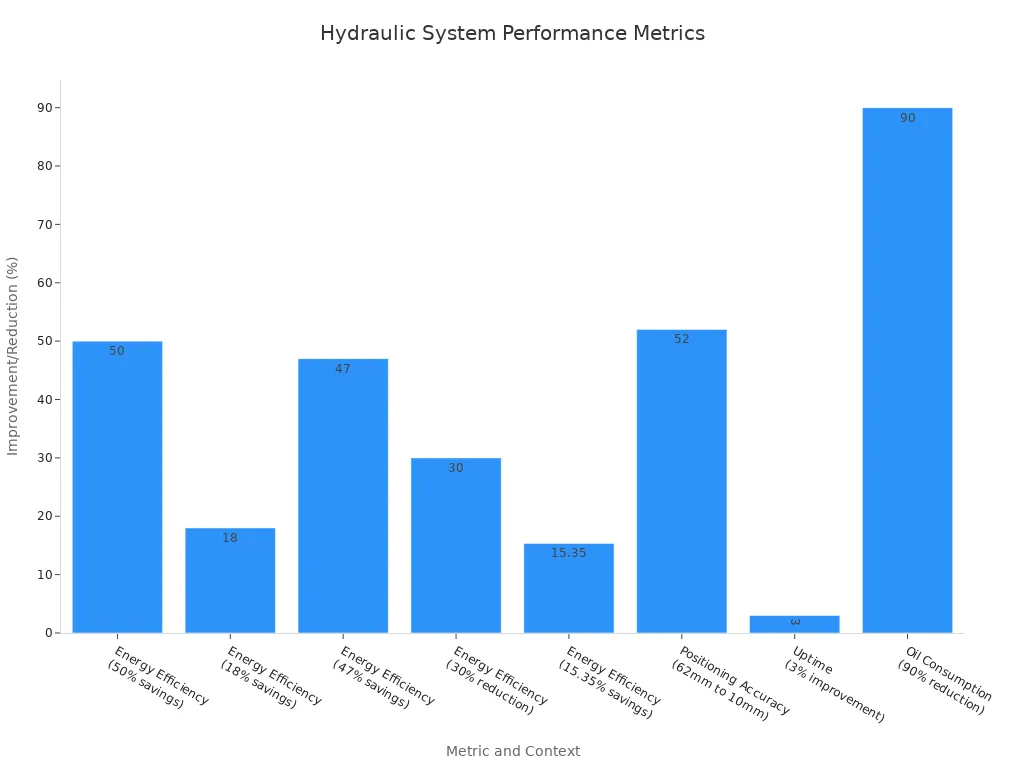

Manufacturers strive for significant improvements in energy efficiency, with some systems achieving up to 50% savings. Positioning accuracy can improve dramatically, moving from 62 mm to within 10 mm. Uptime improvements of 3% can also have a substantial operational impact. These improvements directly contribute to enhanced reliability and cost-effectiveness, which are essential for competitive industrial machinery.

Introducing MODULAR DIRECTIONAL VALVE ELEMENTS MWE6: Engineered for Superior Efficiency

What are MODULAR DIRECTIONAL VALVE ELEMENTS MWE6?

MODULAR DIRECTIONAL VALVE ELEMENTS MWE6 are advanced, solenoid-operated directional valves. They serve a critical function in hydraulic systems: precisely controlling the opening, stopping, and reversing of oil flow. These elements represent Hanshang Hydraulic’s dedication to pioneering hydraulic technology. The company, established in 1988, focuses on designing, developing, and manufacturing high-quality hydraulic components. MWE6 elements reflect this long-standing expertise, providing foundational control for complex industrial machinery. They embody Hanshang Hydraulic’s goal to be a renowned brand in the hydraulic field, offering solutions that meet modern industrial demands.

Key Features Driving Efficiency Gains with MWE6

MWE6 elements incorporate several key features that drive substantial efficiency gains. They enable precise, on-demand flow control. This capability is crucial for optimizing hydraulic system efficiency in various industrial applications. It also leads to a significant reduction in energy waste. This precise control allows machinery to perform tasks with greater accuracy and less wasted power, directly addressing the energy waste challenge. Their modular design simplifies system integration. This reduces assembly time and potential design complexities for manufacturers, streamlining the overall process. The robust construction of MWE6 valves ensures consistent and reliable operation. This minimizes downtime and extends the lifespan of hydraulic systems, improving overall reliability. These features collectively contribute to enhanced machine performance and lower operating costs, fulfilling the manufacturer’s imperative for performance, reliability, and cost-effectiveness.

Direct Benefits for Industrial Machinery Manufacturers with MWE6

Reduced Energy Consumption and Operating Costs

MWE6 valves offer precise control over oil flow. This precision means hydraulic systems use only the energy they need. Less energy goes to waste. Manufacturers see a direct reduction in power consumption. This lowers electricity bills and overall operating costs. Efficient energy use also reduces heat generation. This extends the life of hydraulic fluids and components. It also means less need for large cooling systems.

Enhanced Machine Performance and Precision

The accurate control provided by MWE6 valves improves machine performance. Industrial machinery can execute tasks with greater precision. This leads to higher quality products and fewer errors. Machines respond faster to commands. This increases operational speed and efficiency. For example, robotic arms move more smoothly. Presses apply force more consistently. This enhanced precision directly translates to better output for manufacturers.

Simplified System Design and Integration with MWE6

MODULAR DIRECTIONAL VALVE ELEMENTS MWE6 simplify hydraulic system design. Their modular nature allows for easy assembly. Manufacturers can quickly configure systems for different applications. This reduces design time and engineering effort. The standardized interface options further streamline integration. For instance, various actuator types offer flexible connection possibilities.

| Actuator Type | Interface Option |

|---|---|

| With Modular Universal Actuator | Standard (none) |

| With Modular Universal Actuator | 2″ |

| With Modular Universal Actuator | 3″ |

| With Modular Universal Actuator | 4″ |

| With Modular Universal Actuator | 6″ |

| Universal actuator | Standard (none) |

| Universal actuator | 2″ |

| Universal actuator | 3″ |

| Universal actuator | 4″ |

| Universal actuator | 6″ |

| Manual (not recommended) | 2″ |

| Manual (not recommended) | 3″ |

| Manual (not recommended) | 4″ |

| Manual (not recommended) | 6″ |

| Air actuator | none |

| Air actuator | 2″ |

| Air actuator | 3″ |

| Air actuator | 4″ |

| Air actuator | 6″ |

This wide range of interface options ensures compatibility with diverse machinery. It makes the integration process straightforward. Manufacturers save time and resources during the development phase.

Improved Reliability and Easier Maintenance

MWE6 valves feature robust construction. This design ensures long-term reliability in demanding industrial environments. Durable materials resist wear and tear. This reduces the frequency of breakdowns. Machines experience less downtime. When maintenance is necessary, the modular design simplifies the process. Technicians can easily access and replace components. This reduces repair times and labor costs. The overall system uptime increases significantly. This contributes to a more productive manufacturing operation.

Real-World Applications: Where MODULAR DIRECTIONAL VALVE ELEMENTS MWE6 Excels

Manufacturing and Assembly Lines

MODULAR DIRECTIONAL VALVE ELEMENTS MWE6 significantly enhance manufacturing and assembly lines. They provide precise control for robotic movements. These valves manage clamping and gripping mechanisms with high accuracy. This leads to faster cycle times and improved product quality. Manufacturers use MWE6 elements in automated welding stations. They also appear in material handling systems. The reliable operation of these valves reduces production errors. This helps factories achieve consistent output.

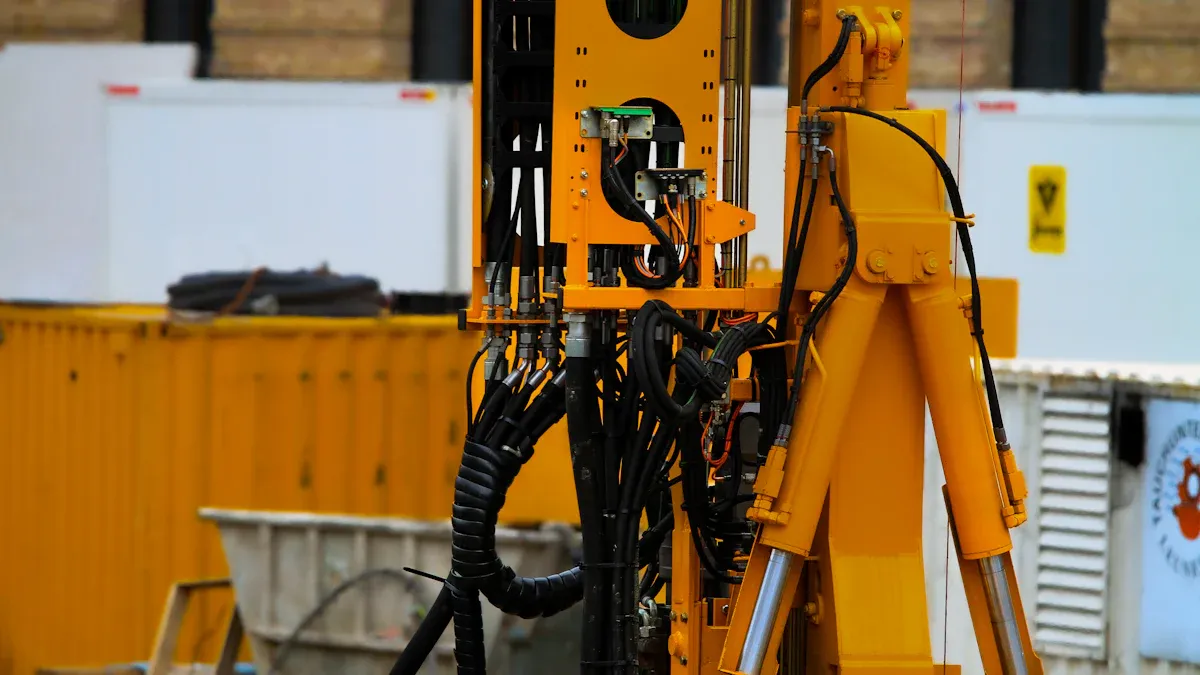

Heavy-Duty Construction Equipment

Heavy-duty construction equipment demands robust and reliable hydraulic control. MODULAR DIRECTIONAL VALVE ELEMENTS MWE6 meet these tough requirements. They control large forces in excavators, bulldozers, and cranes. These valves ensure smooth and powerful operation. Operators experience better control over digging, lifting, and pushing tasks. This improves safety on job sites. It also increases the overall efficiency of construction projects. MWE6 elements withstand harsh environmental conditions.

Agricultural Machinery

Agricultural machinery benefits greatly from the efficiency of MWE6 valves. Farm equipment often operates in challenging outdoor environments. These valves provide reliable control for various implements. They manage the lifting and lowering of plows. They also control the precise movements of harvesters and sprayers. This ensures consistent performance across large fields. Farmers achieve better crop yields. They also reduce fuel consumption. MWE6 elements contribute to more productive and sustainable farming practices.

Choosing the Right MODULAR DIRECTIONAL VALVE ELEMENTS MWE6 Configuration

Factors to Consider: Flow Rate, Pressure, and Actuation Type

Manufacturers must carefully evaluate several critical factors when selecting the right configuration. These include flow rate, pressure, and actuation type. The flow rate dictates the volume of fluid the valve can process. For instance, MODULAR DIRECTIONAL VALVE ELEMENTS MWE6, specifically size 6, can manage a maximum flow rate of 40 L/min. This capacity ensures the hydraulic system receives sufficient fluid for its intended operations. Pressure is another crucial consideration. These valves offer an operating pressure of 31.5 MPa. This high-pressure capability makes them suitable for demanding industrial applications. The actuation type also significantly impacts control. MODULAR DIRECTIONAL VALVE ELEMENTS MWE6 function as solenoid-operated directional spool valves. This design provides precise electronic control over fluid direction. Selecting the correct combination of these factors guarantees optimal system performance and longevity.

| Size | Max flow rate (L/min) |

|---|---|

| 6 | 40 |

| Characteristic | Value |

|---|---|

| Operating pressure | 31.5 MPa |

Integration Tips for Optimal Performance

Proper integration is paramount for achieving optimal performance from any hydraulic system. Manufacturers should actively avoid common pitfalls during installation. Incorrect valve direction can lead to system malfunction. Some valves are designed for specific flow paths; installers must ensure correct orientation. Insufficient space for operation is another issue. Valve handles or actuators require ample room to move freely. Heavy valves can cause pipe misalignment. Providing extra support beneath them helps maintain stability. Larger modular systems often present alignment challenges. In these cases, consider lighter, space-saving valve designs. Always ensure sufficient space around the valve for future maintenance. This makes part replacement much easier. System vibration or thermal expansion can shift alignment over time. Use vibration pads or flexible supports. Regular checks help maintain system stability. Inadequate staff training frequently leads to poor installation practices. Implement proper training, shared practices, and detailed installation checklists. These proactive steps ensure reliable and efficient hydraulic system operation.

Tip: Always ensure adequate room for valve handles or actuators to move freely. Heavy valves can cause pipe misalignment; provide extra support beneath them to maintain stability.

MODULAR DIRECTIONAL VALVE ELEMENTS MWE6 are a strategic investment for industrial machinery manufacturers. They deliver tangible benefits in efficiency, performance, and cost savings. These elements play a crucial role in meeting modern industrial demands for sustainable and high-performing equipment. They embody Hanshang Hydraulic’s goal to be a renowned brand in the hydraulic field. Discover how MODULAR DIRECTIONAL VALVE ELEMENTS MWE6 can transform your hydraulic systems. Contact us today for a consultation or to explore our MWE6 product range.

FAQ

What is the primary function of MODULAR DIRECTIONAL VALVE ELEMENTS MWE6?

MWE6 valves precisely control oil flow in hydraulic systems. They manage the opening, stopping, and reversing of fluid. This ensures accurate machine operation.

How do MWE6 valves reduce energy consumption?

MWE6 valves offer precise flow control. This means hydraulic systems use only necessary energy. This reduces power consumption and lowers operating costs for manufacturers.

Can MODULAR DIRECTIONAL VALVE ELEMENTS MWE6 be used in different industrial applications?

Yes, MWE6 valves excel in various sectors. They enhance manufacturing lines, heavy-duty construction equipment, and agricultural machinery. Their versatility supports diverse industrial needs.