We see how Cetop 3 Solenoid Valves shape the future of hydraulic control. Their reliability stands out every time we work with them. The precision they offer makes every system run smoother. Cetop 3 brings digital integration that fits right into today’s high-tech demands. These valves always deliver.

Key Takeaways

- Cetop 3 Solenoid Valves feature a compact design that allows for easy installation in tight spaces while delivering high flow rates, making them suitable for various hydraulic systems.

- These valves are built for reliability, operating under high pressure and reducing downtime, which is crucial for maintaining productivity in demanding environments.

- Energy efficiency is a key benefit of Cetop 3 Solenoid Valves, as they use advanced designs to lower power consumption and support digital integration for real-time performance monitoring.

Key Features and Technological Advancements of Cetop 3 Solenoid Valves

Compact Design and High Flow Capacity

When we first handled Cetop 3 Solenoid Valves, we noticed how compact they felt in my hands. Their small size makes installation easy, even in tight spaces. Despite their compact build, these valves deliver impressive flow rates. We often check the specs before choosing a valve, and the numbers for Cetop 3 always stand out. Here’s a quick look at their main design specifications:

| Specification | Values |

|---|---|

| Size | 6, 10, 16, 22 |

| Operating Pressure (MPa) | 31.5 |

| Flow Rate (L/min) | 80, 160, 250, 350 |

| Fluid Temperature Range (℃) | -30 to 80 |

| Weight (KGS) | 1, 2.2, 4.7, 8 |

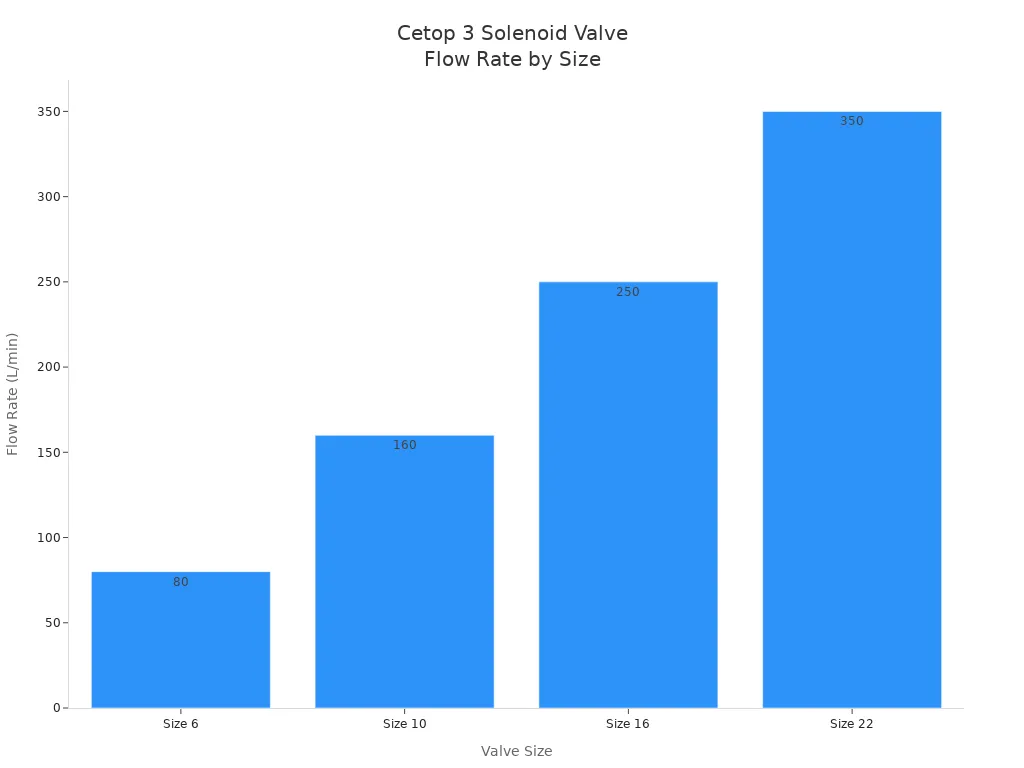

We like to compare flow rates visually. This chart shows how the flow rate increases with valve size:

We see that Cetop 3 Solenoid Valves can handle up to 350 liters per minute. That’s a lot of power packed into a small frame. This combination of size and flow capacity makes them perfect for both large and small hydraulic systems.

Enhanced Reliability and Pressure Resistance

We trust Cetop 3 Solenoid Valves because they perform under pressure—literally. These valves operate at pressures up to 31.5 MPa. We have seen them work smoothly in demanding environments, from heavy machinery to automated production lines. Their robust construction means fewer breakdowns and less downtime. I appreciate that kind of reliability, especially when every minute counts on the job.

Tip: We always recommend checking the pressure rating before installation. Cetop 3 Solenoid Valves rarely disappoint in this area.

Energy Efficiency and Digital Integration

Energy efficiency matters to me, especially with rising energy costs. Cetop 3 Solenoid Valves use advanced coil designs that reduce power consumption. I notice the difference in energy bills over time. These valves also support digital integration. I can connect them to modern control systems and monitor performance in real time. This digital compatibility helps me optimize operations and catch issues early.

Smart Valve Technology and IoT Connectivity

We love how technology keeps moving forward. Cetop 3 Solenoid Valves now feature smart valve technology. We can link them to IoT platforms and get instant updates on valve status, flow rates, and even predictive maintenance alerts. This connectivity gives me peace of mind. We know what’s happening inside our hydraulic system without leaving my desk.

Here’s what stands out to me about these valves:

- Standardized mounting interfaces make installation simple.

- Flow handling adapts to different NG sizes, so I can pick the right valve for any job.

- We see them used everywhere—from heavy-duty machinery to automated factories.

Cetop 3 Solenoid Valves combine compact design, high flow, and smart features. They help me keep my systems efficient, reliable, and ready for the future.

Applications and Selection of Cetop 3 Solenoid Valves

Industrial Automation and Manufacturing

We see Cetop 3 Solenoid Valves everywhere in modern factories. These valves help boost productivity by handling high flow rates and working under tough pressure. We like how they fit into tight spaces and still deliver reliable performance. Here’s a quick table that shows why manufacturers trust them:

| Feature | Description |

|---|---|

| High Flow Capacity | Handles more fluid with less space needed |

| Pressure Capability | Works up to 350 bar |

| Manual Override | Lets me operate the valve during power loss or maintenance |

| Leak-Free Closing | Keeps systems efficient and reliable |

| Optimized Design | Reduces pressure drop for better efficiency |

We rely on these features to keep machines running smoothly and avoid costly downtime.

Mobile Machinery and Renewable Energy Systems

We often use these valves in mobile equipment like construction vehicles and agricultural machines. They handle rough conditions and keep everything moving. In renewable energy, such as wind and solar, I trust them to manage hydraulic flows safely and efficiently. Their compact size and strong build make them perfect for these demanding jobs.

Key Selection Criteria for Hydraulic Systems

When we pick a valve, we look at several important factors. This table helps me remember what matters most:

| Criteria | Description |

|---|---|

| Application Necessities | What job does the valve need to do? |

| System Specifications | What are the pressure, flow rate, and fluid type? |

| Environmental Factors | Will the valve face heat, cold, or dirt? |

| Mounting and Installation | Is there enough space and is it easy to install? |

| Cost and Availability | Does it fit my budget and can I get it quickly? |

| Manufacturer Reputation | Do I trust the brand for quality and support? |

We always check these points before making a choice.

Common Mistakes to Avoid

We’ve learned to watch out for a few common mistakes when working with hydraulic valves:

- Assuming the valve will lower pump flow just by turning off the power.

- Connecting the relief valve vent and pump load sensing together, which can mess up pressure settings.

- Using the vent port for load sensing, which can confuse the system and cause failures.

Tip: Double-check your connections and settings before starting up your system. It saves a lot of trouble later!

We see Cetop 3 Solenoid Valves leading the way in 2025. Their long life, smart features, and easy integration with ISO and CETOP standards make my job easier. We trust them to keep my hydraulic systems running strong. If you want to learn more, check out these top training programs:

| Training Program | Link |

|---|---|

| Hydraulic Safety Awareness | Hydraulic Safety Awareness |

| Advanced Hydraulics Training Course | Advanced Hydraulics Training Course |

FAQ

How do we know if a Cetop 3 Solenoid Valve fits my system?

We always check the valve size, flow rate, and pressure rating. If these match my system specs, I know the valve will work.

Tip: We double-check the mounting interface for a perfect fit.

Can We use Cetop 3 Solenoid Valves in outdoor equipment?

Yes, we use them in mobile and outdoor machines. Their tough build handles dust, moisture, and temperature swings without trouble.

What maintenance do Cetop 3 Solenoid Valves need?

We keep them clean and check for leaks. We also test the coil and wiring. Regular checks help us avoid unexpected downtime.