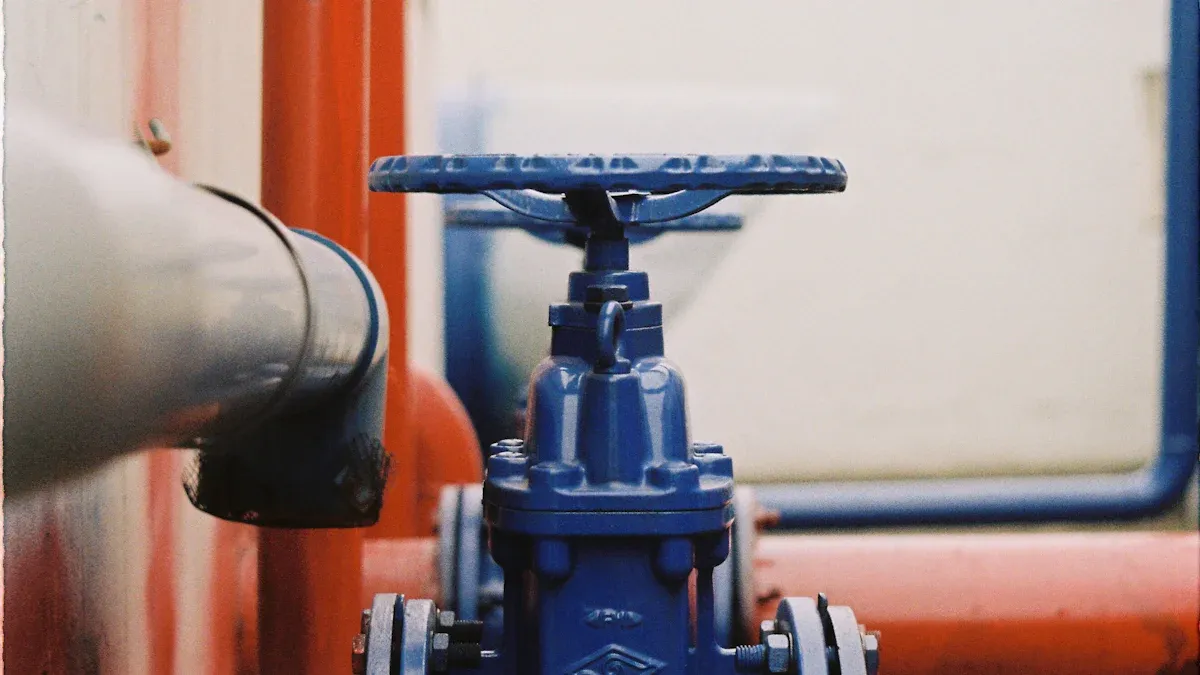

Industrial hydraulic valves and Air Conditioning Fitting Charging Hose Safety Valv serve distinct purposes in specialized systems. Hydraulic valves regulate fluid flow and pressure in industrial machinery, ensuring precise control and efficiency. Safety valves in air conditioning systems protect against overpressure, maintaining system integrity and preventing hazards. Each type of valve features unique designs, materials, and operational mechanisms tailored to its environment. These differences highlight their critical roles in delivering performance and safety in their respective applications.

Key Takeaways

- Hydraulic valves move fluids and control pressure in machines. They help factories work well and stay reliable.

- Safety valves in air conditioning hoses let out extra pressure. This stops parts from breaking and keeps systems safe.

- Taking care of both types of valves is important. It helps them last longer and avoids expensive problems.

- Picking the right valve and putting it in correctly is key. It saves energy, makes systems safer, and works better.

- Knowing what each valve does and what it’s made of helps. It lets workers choose wisely and keep systems running well.

Functional Differences

Purpose and role of industrial hydraulic valves

Industrial hydraulic valves play a pivotal role in manufacturing systems by controlling the flow and pressure of hydraulic fluids. These valves ensure precise fluid regulation, which is essential for maintaining efficiency and consistency in industrial processes. Their primary functions include flow control, pressure relief, and fluid dispensing. By automating valve operations, actuators enhance accuracy and reliability, making these valves indispensable in automated systems.

Tip: Proper valve selection directly impacts the quality of industrial processes, ensuring smooth operations and preventing system failures.

A closer look at their functions reveals the diverse roles they fulfill:

| Function | Description |

|---|---|

| Flow Control | Regulates, isolates, initiates, stops, and alters the direction of fluids. |

| Pressure Relief | Relieves excess pressure from piping systems or pressurized vessels. |

| Quality Assurance | Affects the quality and consistency of industrial processes based on proper valve selection. |

| Fluid Dispensing | Provides reliable fluid service at required flow rates while preventing leakages and backflows. |

| Automation | Actuators automate valve operation for consistent and accurate fluid control. |

Purpose and role of air conditioning hose safety valves

Air conditioning hose safety valves serve as critical components in HVAC systems, safeguarding against overpressure conditions. These valves protect the system’s integrity by releasing excess pressure, preventing damage to hoses, compressors, and other components. Their primary role is to ensure the safe operation of air conditioning systems, especially under fluctuating temperature and pressure conditions.

Unlike industrial hydraulic valves, these safety valves are designed specifically for refrigerant systems. They maintain optimal pressure levels, ensuring efficient cooling performance while minimizing the risk of leaks or ruptures.

Note: Regular inspection of safety valves is crucial to prevent system malfunctions and ensure long-term reliability.

Operational mechanisms of each valve type

Industrial hydraulic valves operate through mechanisms that regulate fluid flow and pressure within hydraulic systems. These mechanisms often involve spool or poppet designs, which shift positions to control fluid movement. Actuators, such as solenoids or manual levers, enable precise control, making these valves suitable for high-pressure environments.

Air conditioning hose safety valves, on the other hand, rely on spring-loaded or diaphragm-based mechanisms. These mechanisms respond to pressure changes by opening or closing the valve to release excess refrigerant. Their design prioritizes quick response times to prevent overpressure conditions, ensuring the safety of HVAC systems.

Both valve types demonstrate unique operational principles tailored to their specific applications, highlighting their importance in maintaining system efficiency and safety.

Structural and Material Differences

Design characteristics of industrial hydraulic valves

Industrial hydraulic valves feature robust designs tailored for high-pressure environments and demanding applications. These valves often incorporate spool or poppet mechanisms, enabling precise control of fluid flow and pressure. Their configurations vary based on function, including control valves, pressure relief valves, and directional valves.

Key specifications include:

- Types of materials selected for durability and corrosion resistance.

- Size variations to accommodate diverse piping systems.

- Pressure ratings designed to withstand hydraulic system demands.

- Multiple ports for application-specific requirements.

- Actuation mechanisms such as manual levers, solenoids, or electro-hydraulic systems.

The cracking point, defined as the moment the valve begins to open, plays a critical role in performance. Rated flow is determined by the metering curve and supply pressure settings, ensuring optimal operation. These design elements make industrial hydraulic valves indispensable for maintaining efficiency and safety in manufacturing systems.

Design characteristics of air conditioning hose safety valves

Air conditioning hose safety valves prioritize safety and reliability in HVAC systems. Their design focuses on preventing overpressure conditions that could damage system components. These valves operate using spring-loaded or diaphragm-based mechanisms, which respond to pressure differentials across the unit.

Key features include:

- Automatic shutoff capabilities to prevent uncontrolled refrigerant flow.

- Quick response times to mitigate hazards associated with pressurized systems.

- Straightforward installation processes, ensuring compliance with safety standards.

When the pressure differential exceeds the operating range, the valve closes to cut off airflow, safeguarding the system. These characteristics highlight the importance of air conditioning hose safety valves in maintaining system integrity and preventing workplace injuries.

Materials used in industrial hydraulic valves

Industrial hydraulic valves utilize advanced materials to ensure durability and reliability under extreme conditions. Common materials include stainless steel and brass, chosen for their corrosion resistance and mechanical strength. AOD-refined alloys enhance wear resistance and minimize intergranular corrosion, while specialized heat treatments improve metallurgical performance.

Surface technologies further optimize valve reliability, addressing challenges such as overheating and insulation failure in solenoid coils. These material innovations ensure that industrial hydraulic valves perform consistently in harsh environments, making them essential components in hydraulic systems.

Materials used in air conditioning hose safety valves

Air conditioning hose safety valves rely on specialized materials to ensure reliability and safety in HVAC systems. Manufacturers select materials based on their ability to withstand refrigerant exposure, temperature fluctuations, and pressure changes.

Common materials include:

- Brass: Offers excellent corrosion resistance and durability, making it ideal for refrigerant systems.

- Stainless Steel: Provides high tensile strength and resistance to extreme temperatures, ensuring long-term performance.

- Aluminum Alloys: Lightweight and cost-effective, suitable for applications requiring moderate strength.

- Rubber and Elastomers: Used for seals and diaphragms, these materials prevent leaks and maintain airtight connections.

Tip: Regular inspection of seals and diaphragms ensures optimal performance and prevents premature wear.

Material selection prioritizes compatibility with refrigerants like R-410A and R-134a. Advanced coatings and treatments enhance resistance to chemical reactions, extending the valve’s lifespan. These materials ensure that air conditioning hose safety valves operate efficiently under demanding conditions.

Durability and performance in different environments

Air conditioning hose safety valves demonstrate exceptional durability across diverse environments. Their design and material composition enable them to perform reliably in residential, commercial, and industrial HVAC systems.

Key performance factors include:

- Temperature Resistance: Valves maintain functionality in extreme heat or cold, ensuring consistent pressure regulation.

- Corrosion Resistance: Materials like stainless steel and brass prevent degradation caused by refrigerants and moisture.

- Pressure Handling: Spring-loaded mechanisms respond effectively to sudden pressure changes, safeguarding system components.

| Environment | Challenges | Performance Features |

|---|---|---|

| Residential HVAC | Fluctuating temperatures | Reliable pressure control |

| Commercial HVAC | High refrigerant flow rates | Enhanced corrosion resistance |

| Industrial HVAC | Extreme pressure conditions | Robust spring-loaded mechanisms |

Note: Proper installation and routine maintenance maximize valve durability and ensure consistent performance.

These valves adapt to varying environmental demands, making them indispensable for maintaining HVAC system integrity and safety. Their durability and efficiency highlight their critical role in preventing system failures and ensuring optimal cooling performance.

Application Differences

Industrial uses of hydraulic valves

Industrial hydraulic valves are essential components in manufacturing, construction, and energy sectors. These valves regulate fluid flow and pressure in hydraulic systems, enabling precise control of machinery and equipment. Industries rely on these valves for tasks such as lifting heavy loads, operating robotic arms, and powering hydraulic presses.

Key applications include:

- Manufacturing: Hydraulic valves control automated systems, ensuring consistent production quality.

- Construction: Heavy machinery like excavators and cranes depend on hydraulic systems for efficient operation.

- Energy: Hydraulic valves play a critical role in wind turbines and oil drilling equipment, optimizing energy output.

The SAE-J1273 Hydraulic Guidelines provide detailed instructions for selecting and maintaining hydraulic systems. These guidelines emphasize proper routing and installation to maximize valve performance and system longevity. Industrial hydraulic valves are indispensable for maintaining operational efficiency in high-pressure environments.

HVAC applications of air conditioning hose safety valves

Air conditioning hose safety valves are vital for maintaining the safety and efficiency of HVAC systems. These valves prevent overpressure conditions, protecting components such as compressors and hoses from damage. Their applications span residential, commercial, and industrial HVAC systems, with the commercial segment accounting for 66% of the market share in 2024.

Key applications include:

- Residential: Safety valves ensure reliable cooling in homes, adapting to fluctuating temperature demands.

- Commercial: Offices and hospitals require complex HVAC systems, increasing the demand for advanced safety valves.

- Industrial: Large-scale facilities rely on these valves to maintain system integrity under extreme conditions.

Approximately 18% of total energy consumption in the U.S. comes from commercial buildings, highlighting the importance of energy-efficient HVAC solutions. Safety valves contribute to this efficiency by preventing refrigerant leaks and ensuring optimal pressure regulation.

System-specific requirements for each valve type

Industrial hydraulic valves must meet stringent requirements to perform under high-pressure conditions. The Valve Standards document outlines specifications for materials, pressure ratings, and actuation mechanisms. These standards ensure compatibility with hydraulic systems and enhance durability in demanding environments.

Air conditioning hose safety valves require materials resistant to refrigerants and temperature fluctuations. Their design must prioritize quick response times to prevent overpressure. Compliance with HVAC industry standards ensures these valves operate reliably across diverse applications.

Both valve types demand careful selection and maintenance to meet system-specific needs. Proper adherence to technical guidelines enhances performance and minimizes the risk of system failures.

Safety and Maintenance Considerations

Safety features of industrial hydraulic valves

Industrial hydraulic valves incorporate advanced safety features to ensure reliable operation in high-pressure environments. These features are designed to prevent system failures, protect equipment, and enhance workplace safety. Certifications play a crucial role in verifying the safety and performance of these valves.

| Certification Type | Description |

|---|---|

| API Monogram Authorization | Ensures compliance with API standards, facilitating global market access and enhancing safety. |

| Design Verification (API Q1) | Confirms that valve designs meet stringent safety and performance criteria. |

| Fire Test (API 6FA) | Evaluates valve reliability under fire conditions to prevent catastrophic failures. |

| Fugitive Emissions Testing (API 624) | Assesses seals under pressure and heat to ensure environmental compliance. |

| ISO 9001 | Certifies that valves are manufactured under robust quality management systems. |

| ISO 15848 | Focuses on leak prevention to protect the environment and ensure operational safety. |

These certifications demonstrate the industry’s commitment to producing valves that meet rigorous safety standards. Features such as pressure relief mechanisms and durable seals further enhance the reliability of industrial hydraulic valves, making them indispensable in high-pressure systems.

Safety features of air conditioning hose safety valves

Air conditioning hose safety valves prioritize user safety by preventing overpressure conditions in HVAC systems. Their design ensures quick response to pressure surges, safeguarding system components and minimizing risks. Compliance with industry standards reinforces their reliability.

- OSHA-compliant air safety check valves cut off airflow during pressure surges, reducing the risk of accidents.

- Proper installation prevents downstream hose failures, protecting users from serious injuries.

- Pressure differential mechanisms maintain system integrity by responding effectively to fluctuations.

These features make air conditioning hose safety valves essential for maintaining safety in residential, commercial, and industrial HVAC systems. Their ability to adapt to varying pressure conditions ensures consistent performance and protection against hazards.

Maintenance practices for industrial hydraulic valves

Regular maintenance is crucial for ensuring the long-term performance and safety of industrial hydraulic valves. Proper upkeep minimizes wear, prevents system failures, and extends the lifespan of these critical components. Recommended practices include:

- Regular Fluid Analysis: Scheduled testing for contamination, viscosity, and additive depletion ensures optimal fluid quality.

- Filtration Excellence: High-quality filters prevent contaminants from damaging valve components.

- Comprehensive Seal Inspection: Routine checks for leaks and proactive seal replacement avoid costly system failures.

- Temperature Management: Maintaining optimal operating temperatures protects valve performance and prevents overheating.

- Professional Valve Cleaning: Detailed cleaning processes remove contamination and ensure smooth operation.

- Preventive Maintenance Schedule: Daily, monthly, quarterly, and annual checks ensure consistent valve performance.

| Key Factors | Description |

|---|---|

| Routine Maintenance | Regular inspections and cleaning to identify wear and prevent failures. |

| Pressure Regulation | Implementing pressure relief valves and monitoring system pressure to prevent hose damage. |

| Use of Protective Accessories | Utilizing hose sleeves and guards to enhance durability and protect against external damage. |

These practices highlight the importance of proactive maintenance in preserving the functionality and safety of industrial hydraulic valves. By adhering to a structured maintenance schedule, operators can ensure reliable performance and reduce the risk of unexpected downtime.

Maintenance practices for air conditioning hose safety valves

Proper maintenance of air conditioning hose safety valves ensures their reliability and extends their lifespan. These valves play a critical role in HVAC systems by preventing overpressure conditions, making regular upkeep essential for optimal performance.

Key Maintenance Practices

- Routine Inspections

Regular visual checks help identify signs of wear, corrosion, or damage. Inspect seals and diaphragms for cracks or leaks, as these components are prone to degradation over time.

- Pressure Testing

Conduct pressure tests to verify the valve’s responsiveness to fluctuating conditions. This practice ensures the valve opens and closes within its designated pressure range, maintaining system safety.

- Cleaning and Lubrication

Clean valve components to remove debris or refrigerant residue that may hinder operation. Apply appropriate lubricants to moving parts to reduce friction and prevent premature wear.

- Seal Replacement

Replace worn-out seals and gaskets promptly to prevent refrigerant leaks. Use materials compatible with the system’s refrigerant type to ensure airtight connections.

- Calibration

Periodically calibrate the valve to maintain its accuracy in pressure regulation. Calibration ensures the valve responds effectively to system demands, minimizing risks.

Tip: Schedule maintenance during system downtime to avoid disruptions in HVAC operations.

Benefits of Regular Maintenance

| Benefit | Description |

|---|---|

| Enhanced Safety | Prevents overpressure conditions that could damage system components. |

| Prolonged Lifespan | Reduces wear and tear, extending the valve’s operational life. |

| Improved Efficiency | Ensures consistent pressure regulation for optimal cooling performance. |

| Reduced Costs | Minimizes the need for costly repairs or replacements due to system failures. |

Regular maintenance practices not only safeguard the valve but also contribute to the overall efficiency and reliability of HVAC systems.

Common issues and troubleshooting for each valve type

Both industrial hydraulic valves and air conditioning hose safety valves encounter operational challenges that require effective troubleshooting. Understanding common issues helps technicians address problems promptly, ensuring system functionality.

Common Issues

| Valve Type | Issue | Cause |

|---|---|---|

| Industrial Hydraulic Valves | Fluid leakage | Worn seals or improper installation |

| Pressure instability | Contaminated hydraulic fluid or clogged filters | |

| Valve sticking | Debris accumulation or inadequate lubrication | |

| Air Conditioning Hose Safety Valves | Refrigerant leaks | Damaged seals or diaphragm failure |

| Valve not opening | Incorrect pressure calibration or spring failure | |

| Corrosion | Exposure to moisture or incompatible materials |

Troubleshooting Techniques

- Industrial Hydraulic Valves

- Fluid Leakage: Replace worn seals and ensure proper installation. Inspect piping connections for tightness.

- Pressure Instability: Flush the hydraulic system to remove contaminants. Replace clogged filters to restore fluid flow.

- Valve Sticking: Clean valve components thoroughly and apply high-quality lubricants to reduce friction.

- Air Conditioning Hose Safety Valves

- Refrigerant Leaks: Replace damaged seals and diaphragms with compatible materials. Conduct pressure tests to verify airtight connections.

- Valve Not Opening: Recalibrate the valve to match system pressure requirements. Inspect the spring mechanism for wear or damage.

- Corrosion: Use corrosion-resistant materials and apply protective coatings to exposed components.

Industry Insights

Industry reports emphasize the importance of selecting the right valves and maintaining them effectively to prevent operational issues. For example:

| Title | Description |

|---|---|

| How Valve Selection Impacts Pump Station Safety and Protection | Highlights the role of proper valve selection in enhancing safety and efficiency in pump stations. |

| Hydraulic Power Unit Troubleshooting | Discusses the necessity of regular maintenance and sufficient reservoir size for hydraulic systems. |

| A Review Study in Troubleshooting of Hydraulic Systems in Cement Industries | Reviews critical hydraulic system components and their functions for effective troubleshooting. |

Note: Technicians should follow industry guidelines and best practices to address valve-related issues efficiently.

By identifying common problems and implementing targeted solutions, operators can ensure the reliability and safety of both valve types in their respective systems.

Industrial hydraulic valves and air conditioning hose safety valves serve distinct purposes, each tailored to its specific system requirements. Selecting the appropriate valve type ensures optimal performance and safety. Proper valve connections enhance system design by enabling efficient fittings, reducing energy loss, and controlling maintenance costs. Knowledge of valve mechanisms aids in troubleshooting, preventing issues like leaks or failures. Understanding these differences allows operators to make informed decisions, ensuring system reliability and cost-effectiveness.

FAQ

1. What is the primary difference between industrial hydraulic valves and air conditioning hose safety valves?

Industrial hydraulic valves regulate fluid flow and pressure in machinery, ensuring precise control. Air conditioning hose safety valves protect HVAC systems by releasing excess pressure, preventing damage. Each serves a distinct purpose tailored to its application.

2. Can industrial hydraulic valves be used in HVAC systems?

No, industrial hydraulic valves are not suitable for HVAC systems. Their design and materials cater to high-pressure hydraulic fluids, while HVAC systems require valves compatible with refrigerants and temperature fluctuations.

3. How often should air conditioning hose safety valves be inspected?

Technicians should inspect air conditioning hose safety valves every six months. Regular inspections help identify wear, leaks, or pressure calibration issues, ensuring system safety and efficiency.

4. What materials are commonly used in industrial hydraulic valves?

Industrial hydraulic valves often use stainless steel, brass, or AOD-refined alloys. These materials provide durability, corrosion resistance, and strength for high-pressure environments.

5. Why is maintenance important for both valve types?

Maintenance ensures optimal performance, extends the lifespan of valves, and prevents system failures. Regular upkeep minimizes risks like leaks, pressure instability, or component damage, safeguarding the entire system.