Selecting the optimal NG6 hydraulic valve manifold presents a critical challenge for heavy-duty industrial OEMs. This decision directly impacts system performance, durability, and cost-effectiveness. It also affects seamless integration into machinery. This guide helps OEMs make informed manifold selections.

Selecting the optimal NG6 hydraulic valve manifold presents a critical challenge for heavy-duty industrial OEMs. This decision directly impacts system performance, durability, and cost-effectiveness. It also affects seamless integration into machinery. This guide helps OEMs make informed manifold selections.

Key Takeaways

- NG6 hydraulic manifolds combine many valves. This makes hydraulic systems smaller. It also helps prevent leaks and makes repairs easier.

- Choosing the right NG6 manifold means looking at pressure, flow, and materials. Steel is good for tough jobs. Aluminum is light.

- Always check that the manifold and valves fit together. Also, pick a supplier who offers good support and a strong warranty.

Understanding NG6 Hydraulic Manifolds: Fundamentals for OEMs

What Defines NG6 Hydraulic Valve Manifolds?

What Defines NG6 Hydraulic Valve Manifolds?

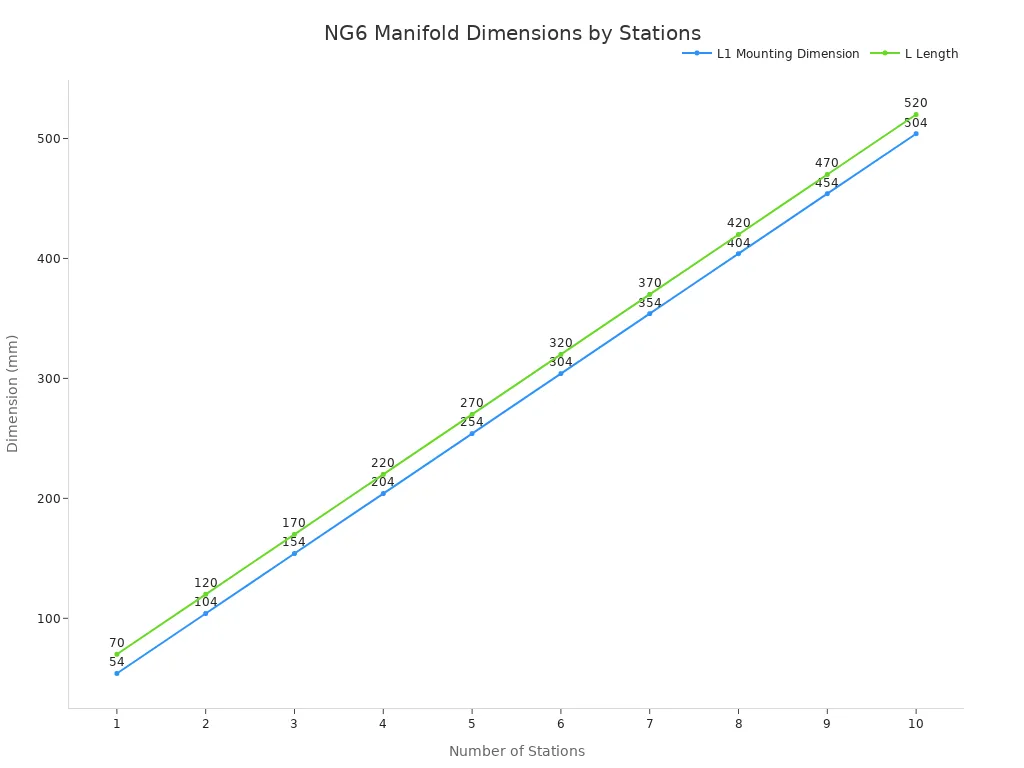

NG6 hydraulic valve manifolds represent a global standard for integrating hydraulic valves. This standard is known as CETOP 3/D03, ISO 4401-03, and DIN 24340 A. It provides a common interface for mounting valves onto a manifold block. This standardization ensures interchangeability and simplifies system design across different manufacturers. The physical dimensions and mounting patterns are precisely defined. For example, a manifold’s length and mounting dimensions increase predictably with the number of valve stations.

| Number of Stations | L1 Mounting Dimension (mm) | L Length (mm) |

|---|---|---|

| 1 | 54 | 70 |

| 2 | 104 | 120 |

| 3 | 154 | 170 |

| 4 | 204 | 220 |

| 5 | 254 | 270 |

| 6 | 304 | 320 |

| 7 | 354 | 370 |

| 8 | 404 | 420 |

| 9 | 454 | 470 |

| 10 | 504 | 520 |

Core Benefits of NG6 Manifolds for Heavy-Duty Applications

NG6 manifolds offer several advantages for heavy-duty industrial OEMs. They allow for the integrated installation of multiple valves. This creates a more compact hydraulic system. A unified oil port layout reduces the number of external pipes and fittings. This significantly lowers the risk of leaks, which is crucial in demanding environments. Manifolds also simplify maintenance and valve replacement. Technicians can easily access and swap out individual valves without disturbing the entire hydraulic circuit. These manifolds are designed to handle specific performance requirements. For instance, many NG6 manifolds can manage pressures up to 350 bar (approximately 5076 psi) and flow rates ranging from 30 to 70 liters per minute (approximately 8 to 18.5 GPM), depending on the specific model and whether it includes features like a relief valve. This robust capability makes them suitable for various heavy-duty machinery.

Critical Performance Criteria for NG6 Manifold Selection

Pressure and Flow Rating Compatibility for NG6 Systems

OEMs must select NG6 manifolds that match the hydraulic system’s pressure and flow demands. Manifolds handle various pressure and flow levels. For example, some models offer different capabilities:

| Feature | Standard Model | Enhanced Model | Premium Model | Pro Model (Heavy-Duty) |

|---|---|---|---|---|

| Pressure Rating | 300 bar | 345 bar (+15%) | 390 bar (+30%) | Up to 390 bar |

| Flow Capacity | 80 L/min | 95 L/min | 110 L/min | N/A |

The Raypoo 03-2w Parallel Circuit Manifold, for instance, handles a maximum pressure of 31.5 MPa and a maximum flow rate of 120 L/min. OEMs should choose a manifold that meets or exceeds the system’s peak operating conditions.

Material Selection and Durability for NG6 Manifolds

The manifold’s material directly affects its durability and lifespan. Common materials include aluminum, ductile iron, and steel. Aluminum offers lightweight properties, suitable for applications where weight is a concern. Ductile iron provides good strength and vibration dampening. Steel, especially alloy steel, offers superior strength and wear resistance for the most demanding heavy-duty applications.

“We installed the Pro Model NG6 Cetop 3 manifold in our hydraulic press line, and it’s been rock-solid under 380 bar pressure cycles. The alloy steel construction shows zero signs of wear after six months of 24/7 operation.”

This demonstrates the importance of robust material choices for continuous operation.

Optimizing Porting Options and NG6 Manifold Configuration

Manifold configuration involves selecting the correct porting options. This includes the number of valve stations, port sizes, and internal passage designs. OEMs can choose parallel or series circuits, depending on the application’s needs. Proper porting minimizes pressure drops and ensures efficient fluid flow. This optimization directly impacts system performance and energy efficiency.

Ensuring Valve Compatibility with NG6 Interfaces

OEMs must ensure complete compatibility between the manifold and the valves. NG6 interfaces are standardized, but variations exist in valve mounting patterns and port locations. Always verify that the chosen valves perfectly align with the manifold’s drilling pattern and internal passages. This prevents leaks and ensures proper valve function.

Operational and Environmental Considerations for NG6 Manifolds

Operating Temperature Range for NG6 Hydraulic Systems

OEMs must consider the operating temperature range for NG6 hydraulic systems. Extreme temperatures affect fluid viscosity and component integrity. High temperatures degrade seals and hydraulic fluids. Low temperatures increase fluid viscosity, which can cause sluggish operation and cavitation. Manufacturers specify the safe operating temperature range for their manifolds. Selecting a manifold that performs reliably within the expected environmental temperatures ensures system longevity.

Fluid Compatibility for NG6 Manifold Applications

The hydraulic fluid used in the system must be compatible with the manifold’s materials and seals. Incompatible fluids can cause corrosion, swelling, or degradation of seals. This leads to leaks and system failure. Common hydraulic fluids include mineral oils, synthetic fluids, and fire-resistant fluids. OEMs must verify that the chosen manifold materials, such as aluminum or steel, and seal types, like NBR or FKM, are suitable for the specific fluid.

Contamination Resistance in NG6 Manifold Design

Contamination is a major cause of hydraulic system failure. Manifold design plays a role in contamination resistance. Internal passages should minimize areas where contaminants can settle. Smooth internal finishes also help prevent particle buildup. Proper filtration upstream of the manifold is essential. A well-designed manifold contributes to a cleaner hydraulic system, extending the life of valves and other components.

Vibration and Shock Resistance of NG6 Manifolds

Heavy-duty industrial applications often expose hydraulic components to significant vibration and shock. Manifolds must withstand these forces without cracking or leaking. Robust construction and secure mounting are critical. Manufacturers test manifolds for their resistance to these environmental stresses. These tests include:

- Sine test according to DIN EN 60068-2-6

- Noise test according to DIN EN 60068-2-64

- Transport shock according to DIN EN 60068-2-27

Selecting manifolds proven to endure such conditions ensures reliable operation in harsh environments.

Integration, Maintenance, and Cost Factors for NG6 Manifolds

Ease of Mounting and Installation for NG6 Manifolds

OEMs value straightforward installation. NG6 manifolds simplify the assembly process. Their standardized mounting patterns mean quick and accurate positioning. This reduces labor time and potential errors during machine construction. The compact design also allows for easier integration into tight spaces within heavy-duty equipment. Fewer external hoses and fittings contribute to a cleaner, more organized system layout.

Maintenance and Serviceability of NG6 Hydraulic Manifolds

Effective maintenance is crucial for operational uptime. NG6 manifolds enhance serviceability. Technicians can easily access individual valves mounted on the manifold. This allows for quick inspection, repair, or replacement of components without disturbing the entire hydraulic circuit. The integrated design also reduces the number of potential leak points, simplifying troubleshooting and preventing costly fluid loss.

Cost-Benefit Analysis for NG6 Manifold Investments

Investing in NG6 manifolds involves an initial cost. However, OEMs gain significant long-term benefits. These include reduced assembly time, lower material costs due to fewer fittings, and decreased labor for installation. The enhanced reliability and easier maintenance lead to less downtime and lower operational expenses over the machine’s lifespan. This makes them a cost-effective choice for heavy-duty applications.

Customization vs. Standard NG6 Manifold Solutions

OEMs often face a choice between standard and customized NG6 manifold solutions. Standard manifolds offer quick availability and lower upfront costs. They suit common applications well. Custom manifolds, however, provide precise optimization for unique system requirements. They can integrate specific valve functions, optimize porting for minimal pressure drop, and fit exact spatial constraints. While custom solutions have higher initial costs and longer lead times, they can deliver superior performance and efficiency for highly specialized machinery.

Supplier Evaluation and Support for NG6 Manifold Procurement

Assessing Supplier Reputation and Experience for NG6 Components

OEMs must carefully evaluate potential suppliers for NG6 manifolds. A reputable supplier demonstrates extensive experience in hydraulic components. They should hold relevant certifications. These include ISO, CETOP, NFPA, and DIN standards. Specific certifications like ISO 7368 and CETOP NG6/NG10 confirm their adherence to industry benchmarks. OEMs should assess suppliers based on performance metrics. These include on-time delivery rates and response times. A high on-time delivery rate, ideally ≥98%, indicates reliability.

Technical Support and Documentation for NG6 Manifolds

Suppliers should offer robust technical support and comprehensive documentation. OEMs expect technical drawings within 72 hours. CAD model availability is also crucial for seamless integration. Quality assurance documentation is essential. This includes dimensional inspection reports and pressure testing reports. Pressure tests should be at 1.5 times the operating range. Material traceability, such as EN AW-6082 aluminum, and surface treatment certifications like MIL-A-8625 for anodizing, are also necessary. Leading manufacturers provide test certificates. These validate performance metrics like leakage rates and fatigue life.

Lead Times and Supply Chain Reliability for NG6 Orders

Understanding lead times and supply chain reliability is vital. Standard NG6 subplates typically have a delivery lead time of 15 to 20 days. This can vary with order quantity. Customization options are available for specific needs. OEMs must also consider supply chain risks. These include quality inconsistencies and delayed shipments. Mitigation strategies involve sample testing and factory audits. Negotiating clear defect resolution SLAs helps manage issues.

| Performance Indicator | Ideal Benchmark | Risk of Non-Compliance |

|---|---|---|

| On-Time Delivery Rate | ≥98% | Production delays, inventory shortages |

| Response Time | ≤5 hours | Slow issue resolution, communication gaps |

Warranty and After-Sales Service for NG6 Manifold Products

A strong warranty and reliable after-sales service are critical. The standard warranty period for NG6 manifold products is typically one year. This starts from the delivery date to the destination port, assuming no artificial damage. Crucial after-sales services include 24/7 technical support. OEMs also need spare parts availability. Quick response times for service requests, preferably under two hours, are highly valued. Comprehensive warranty terms, with minimum 12 months and extended options, provide long-term peace of mind.

Strategic selection of NG6 hydraulic valve manifolds is paramount for heavy-duty industrial OEMs. A comprehensive evaluation of performance, durability, environmental factors, integration, and supplier support is crucial. This holistic approach ensures optimal system design, long-term reliability, and maximized return on investment. For example, achieving a leakage rate of ≤ 0.01 ml/min and a cycle life of ≥ 50,000 cycles are key for successful integration.

FAQ

What is the primary advantage of NG6 manifolds?

NG6 manifolds integrate multiple valves. This creates compact hydraulic systems. It reduces leaks and simplifies maintenance.

What materials are typically used for NG6 manifolds?

Common materials include aluminum, ductile iron, and steel. Each material offers specific properties for different application needs.

How does NG6 standardization benefit system design?

NG6 standardization ensures interchangeability. It simplifies system design across various manufacturers. This makes component selection easier.