High-pressure hydraulic blocks allow for compact designs and increased power density in heavy-duty construction machinery. These components improve control precision and decrease energy losses within the hydraulic system. This directly leads to better fuel economy, quicker cycle times, and higher operational productivity.

High-pressure hydraulic blocks allow for compact designs and increased power density in heavy-duty construction machinery. These components improve control precision and decrease energy losses within the hydraulic system. This directly leads to better fuel economy, quicker cycle times, and higher operational productivity.

Key Takeaways

- High-pressure hydraulic blocks make heavy machines stronger and smaller. They help machines do more work with less fuel.

- These blocks make machines move more precisely. They also help machines respond faster to commands.

- High-pressure blocks save energy. They also make machine parts last longer.

The Foundation of High-Pressure Hydraulic Blocks

Defining High-Pressure Hydraulic Blocks

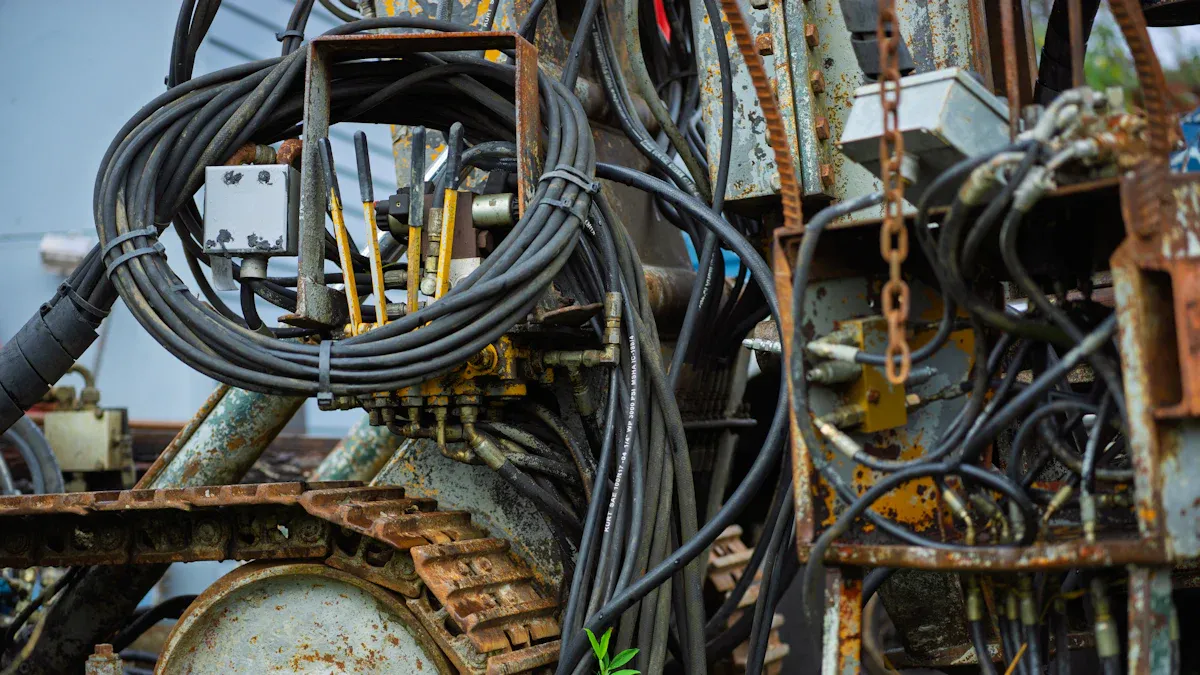

A hydraulic block acts as a central manifold in hydraulic systems. It integrates various hydraulic valves, connectors, and other components. This design replaces traditional, bulky pipe connections. The block performs essential control functions such as oil distribution, direction changes, and pressure regulation. Hanshang Hydraulic, with its roots tracing back to 1988, specializes in the design, research, and manufacturing of these critical components. The company’s spirit of leading innovation and its pursuit of excellence are foundational to its development. Hanshang Hydraulic aims to forge a renowned brand in the hydraulic field.

The Efficiency Advantage of Higher Pressure

Higher pressure in hydraulic systems provides substantial efficiency advantages. High-pressure hydraulic systems typically operate within a range of 3,000 to 6,000 PSI (210 to 420 bar). This pressure range is now the modern standard for high-performance applications. Heavy construction equipment, including excavators and loaders, commonly operates within these high-pressure parameters. Operating at elevated pressures allows smaller components to transmit the same amount of power. This results in more compact designs and significantly increased power density. A smaller hydraulic block can manage greater forces, making machinery more agile and powerful without increasing its overall footprint. This efficiency gain directly supports Hanshang Hydraulic’s mission to provide stable and reliable hydraulic products, ensuring customer satisfaction and market reputation.

Mechanisms: How High-Pressure Hydraulic Blocks Boost Efficiency

Increased Power Density and Compact Design

High-pressure hydraulic blocks fundamentally change how heavy-duty machinery operates. They allow engineers to design more powerful systems in smaller spaces. Higher operating pressures mean smaller components can transmit the same amount of power. This leads to a significant increase in power density. A compact, modular design is a key feature. This design allows for easy integration into both new and existing hydraulic systems. It also simplifies maintenance because technicians can service individual valves without disassembling the entire block. The compact layout saves valuable space by consolidating multiple valve functions into a single assembly. This integration reduces the overall weight and size of the hydraulic system. Optimized circuitry within the hydraulic block aids installation and saves space. Hydraulic blocks can integrate numerous control functions into one unit. They often use multi-function cartridge valves. This leads to more compact designs and allows for complex control behaviors.

Reduced Energy Losses and Improved Thermal Management

Conventional hydraulic systems often lose energy in various ways. Pumps can experience internal wear, leading to fluid leakage and reduced pressure. Cavitation can occur due to inadequate fluid draw, causing noise and wear. Control system problems in variable displacement pumps also contribute to losses. Fluid-related issues, such as contamination or incorrect viscosity, accelerate component wear. Temperature extremes, like overheated or cold fluid, also affect efficiency. Clogged filters create pressure drops. Internal leakage in control valves and relief valves set too low are common valve issues. Pressure losses occur in lines due to friction and flow deflection. They also happen in valves and accessories like filters and coolers. Throttling is a significant source of loss, especially in constant pressure systems. Leakage losses happen at points requiring sealing. Energy losses in hydraulic systems primarily occur as mechanical losses due to fluid friction. Volumetric losses also happen due to internal fluid leakage. High fluid viscosity increases mechanical losses. Low fluid viscosity leads to higher volumetric losses. High-pressure hydraulic blocks minimize these losses. They achieve this through optimized internal passages and reduced connection points. This reduction in energy waste directly improves thermal management. Less energy converts to heat, keeping the system cooler and extending component life.

Enhanced Control Precision and Responsiveness

High-pressure hydraulic blocks significantly improve control precision and responsiveness. They feature precise drill holes for fluid connections. These holes ensure low-loss routing of hydraulic fluid. They also serve as receptacles for screw-in valves, enabling accurate control. Integrating multiple valves and connections into a compact unit reduces leakage points. This also minimizes pressure losses. The result is more precise control over machinery movements. Continuous integration of control functions minimizes connection points. This reduces potential leakage sources. It enhances overall system reliability and control accuracy. Flow-optimized internal channels, often found in cast control blocks, minimize flow resistance and pressure losses. This allows for more consistent and precise fluid delivery to actuators. Precisely positioned holes within the block ensure efficient and low-loss routing of hydraulic fluid. This is crucial for accurate control of heavy-duty equipment.

Optimized Flow Paths and System Integration in the Hydraulic Block

Optimizing flow paths within the hydraulic block is crucial for efficiency. Additive manufacturing, specifically through an ‘Additive Investment Casting process,’ allows for the optimization of internal flow pathways. This can happen while maintaining the external geometry of the block. This method enhances flow efficiency without altering the external form factor. Designers simplify the oil circuit to be as straightforward as possible. They minimize the number of deep holes, slant holes, and process holes. They ensure through-apertures have adequate flow area, especially for flow-matching valve blocks. Inlets and outlets are positioned to align with the overall system layout and pipeline connections. System integration within the hydraulic block consolidates flow paths into one solid block. This eliminates the need for complicated external piping. This setup improves fluid control, pressure management, and overall speed. Key components like directional valves, high-pressure connectors, and machined internal passages work together. They minimize space and maintain precise flow control. Internal passages machined to 5–7 µm surface precision reduce turbulence and energy losses. Integrating directional and flow control valves directly into the main hydraulic block reduces potential leak points. It also minimizes turbulence and pressure drops. This leads to increased energy efficiency by reducing unnecessary energy expenditure. Integration cuts down on pressure loss by about 30 percent compared to traditional tubing setups. Industrial systems see a 60 to 80 percent reduction in potential leak spots. Strategic valve placement within manifolds can drop operating temperatures by 12 to 15 degrees Celsius. Compact manifold designs boost energy efficiency by 12 to 15 percent in construction machines. CFD-optimized layouts achieve up to 35% lower pressure drops than conventional designs. Additive manufacturing reduces turbulent flow by 60% in compact manifolds and weight by 28% compared to milled aluminum blocks.

Tangible Benefits for Heavy-Duty Construction Machinery

High-pressure hydraulic blocks deliver significant advantages for heavy-duty construction machinery. These benefits directly impact operational efficiency, cost-effectiveness, and environmental responsibility.

Fuel Economy and Reduced Operating Costs

High-pressure hydraulic systems inherently save fuel. They achieve the same work with less fluid, reducing the energy demand on the engine. This directly translates into lower fuel consumption. For example, advanced hydraulic technologies show impressive fuel economy improvements:

| Source | Technology | Machine Type | Fuel Economy Improvement |

|---|---|---|---|

| Danfoss Power Solutions | Digital Displacement pump technology | Not specified (general application) | 15-30% efficiency increases |

| Volvo Construction Equipment | Digital hydraulic actuator | 30-ton excavator (prototype testing) | 50% fuel efficiency improvement |

Beyond fuel savings, high-pressure hydraulic blocks reduce operating costs by enhancing durability and simplifying maintenance. Systems designed with a ‘simple, all-hydraulic’ philosophy prevent failures and associated downtime in harsh environments. These robust hydraulic designs avoid delicate electronics and complex controllers. The absence of complex computerization, relays, connectors, and wiring harnesses makes troubleshooting and repairs significantly easier and quicker. This minimizes the time a machine remains out of operation. This straightforward design philosophy contributes to lower overall operating expenses by reducing the frequency and complexity of repairs. Hanshang Hydraulic ensures its products offer stable quality and reliability, directly supporting these cost-saving measures.

The Sennebogen 870-E’s all-hydraulic system, built for durability and reliability, further exemplifies reduced operating costs. It eliminates the need for special software or ‘black-box’ components for troubleshooting. This design choice ensures the machine is powerful, easy to operate, and maintain, relying only on proven components. This simplicity directly translates to lower maintenance costs and less downtime. Repairs become less complex and quicker to execute.

Increased Productivity and Faster Cycle Times

High-pressure hydraulic blocks significantly boost productivity by enabling faster cycle times. Heavy-duty hydraulics, often incorporating axial piston pumps, enhance speed and precision in construction. These systems increase lifting power and ‘flight rate’ in excavators. This directly enables faster performance and reduced cycle times in material handling machinery.

Hydraulic pressure intensifiers play a significant role in accelerating heavy-duty construction tasks. They deliver the necessary force for equipment like hydraulic presses and pile drivers. Industry data indicates that using these intensifiers can increase force output by up to 50%. This directly translates to faster project completion. It achieves deeper penetration with fewer cycles in operations such as pile driving.

High-pressure hydraulic blocks contribute to faster cycle times by enabling higher flow rates. As Volvo Excavator Hydraulics explains, “Flow controls excavator speeds.” Increased flow directly leads to faster boom, arm, and bucket movements. This allows operators to complete tasks more quickly. Furthermore, Volvo’s ‘Summation System’ combines flow from both hydraulic pumps. This ensures quick cycle times and high productivity, particularly for demanding applications like large-scale earthmoving.

Extended Component Lifespan and Reliability

High-pressure hydraulic blocks contribute to extended component lifespan and overall system reliability. Their optimized internal passages and reduced connection points minimize energy losses. This reduction in energy waste directly improves thermal management. Less energy converts to heat, keeping the system cooler. Cooler operating temperatures reduce stress on seals, hoses, and other components. This prevents premature wear and extends their operational life.

The compact and integrated design of these blocks also reduces the number of potential leak points. Fewer leaks mean less fluid contamination and less exposure to external elements. This protects internal components from damage. Hanshang Hydraulic‘s commitment to quality and stable products ensures that these blocks meet rigorous standards. This further enhances the reliability of the entire hydraulic system. The robust design philosophy, which prioritizes durability and simplicity, also means fewer complex parts that could fail. This leads to a more dependable machine with less downtime for repairs.

Environmental Impact and Sustainability

High-pressure hydraulic blocks play a crucial role in reducing the environmental impact of heavy-duty construction machinery. Modern hydraulic systems are designed for energy efficiency. They incorporate technologies such as variable speed drives and load-sensing systems. These systems optimize energy use by adjusting pump speed and pressure according to demand. Regenerative circuits further minimize consumption by capturing and reusing energy.

The hydraulics industry moves towards energy-efficient solutions. It aims to reduce environmental impact without compromising performance. Innovative technologies and smarter system designs emerge to meet this challenge. Optimizing energy use is a strategic move towards sustainability and operational cost savings.

High-pressure hydraulic blocks contribute to a reduced environmental footprint through several key aspects:

- Reduced carbon emissions.

- Minimized material waste.

- Compatibility with eco-friendly materials like fly ash and recycled aggregates.

- Reduced environmental footprint, supporting sustainable construction practices.

These advancements align with Hanshang Hydraulic’s goal of forging a renowned brand in the hydraulic field. They provide solutions that are both powerful and environmentally responsible.

High-pressure hydraulic blocks are fundamental for superior efficiency in modern heavy-duty construction machinery. They deliver more power in a smaller, controlled, and energy-efficient package. This provides significant operational advantages. These hydraulic blocks are indispensable for maximizing productivity and profitability in the construction industry.

FAQ

What is a high-pressure hydraulic block?

A high-pressure hydraulic block integrates various hydraulic valves and components. It replaces traditional piping. This block controls oil distribution, direction changes, and pressure regulation within a hydraulic system.

How do high-pressure hydraulic blocks improve fuel economy?

High-pressure blocks reduce energy losses through optimized internal passages. They also have fewer connection points. This minimizes wasted energy, which means less demand on the engine. This directly lowers fuel consumption.

What are the benefits of their compact design?

Compact designs allow more power in smaller spaces. This increases power density. It also simplifies maintenance and reduces the overall weight and size of the hydraulic system. This makes machinery more agile.