Industrial sectors demand components that ensure operational safety and efficiency. ISO 9001 certified direct operated pressure relief valves, including PBD direct operated pressure relief valves, meet these requirements, offering durability and reliability. Bulk ordering these valves enhances cost management and logistics. Studies show aging effects on such valves are minimal, with failure rates dropping over time, confirming their long-term performance.

Key Takeaways

- Buying many direct operated pressure relief valves saves money. Companies spend less per valve and cut extra costs, helping them use resources better.

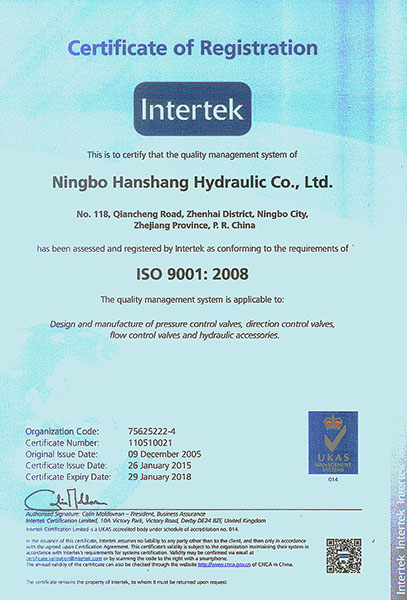

- ISO 9001 certification proves the valves are high quality and reliable. This lowers risks and makes industrial work safer.

- Picking a trusted seller with good reviews and strong certifications is important. It ensures the valves work well and support is helpful, improving efficiency.

Benefits of Bulk Ordering DIRECT OPERATED PRESSURE RELIEF VALVES

Cost Efficiency in Bulk Purchases

Bulk purchasing of direct operated pressure relief valves offers significant cost advantages for industrial operations. Suppliers often provide discounted rates for large orders, reducing the per-unit cost. This approach minimizes procurement expenses and allows businesses to allocate resources more effectively. For example, a specialty care center achieved savings of $1.6 million by standardizing supply usage and leveraging bulk purchasing practices. Such financial benefits highlight the importance of strategic procurement in industrial settings.

Additionally, bulk orders reduce the frequency of individual purchases, cutting down on administrative costs and time spent on repeated transactions. This streamlined approach not only saves money but also enhances operational efficiency, ensuring that businesses can focus on their core activities without unnecessary interruptions.

Simplified Procurement and Logistics

Managing procurement and logistics becomes more straightforward with bulk orders. Instead of coordinating multiple small shipments, businesses can consolidate their needs into a single, large order. This reduces the complexity of supply chain management and minimizes the risk of delays or errors in delivery.

Bulk ordering also ensures consistent availability of direct operated pressure relief valves, preventing potential downtime caused by stock shortages. For industries that rely on uninterrupted operations, such as manufacturing or utilities, this reliability is crucial. By simplifying procurement processes, companies can maintain a steady supply of high-quality components while reducing logistical challenges.

Enhanced Inventory Management for Industrial Needs

Maintaining an adequate inventory of essential components is vital for industrial operations. Bulk ordering direct operated pressure relief valves allows businesses to optimize their inventory levels, ensuring they have sufficient stock to meet demand without overstocking. This balance reduces storage costs and minimizes the risk of obsolescence.

Lower water pressure, achieved through the use of these valves, extends the lifespan of industrial equipment. This reduces the frequency of maintenance and replacement, further enhancing inventory management. For instance, studies have shown that lower water pressure can decrease service calls and prevent water damage, leading to long-term savings.

Moreover, bulk purchasing supports better forecasting and planning. With a clear understanding of inventory levels, businesses can anticipate future needs and adjust their procurement strategies accordingly. This proactive approach ensures that operations run smoothly, even during periods of high demand.

Features of DIRECT OPERATED PRESSURE RELIEF VALVES

Key Functionalities and Design Aspects

DIRECT OPERATED PRESSURE RELIEF VALVES are engineered to provide precise pressure regulation and reliable performance in demanding industrial environments. Their compact design ensures seamless integration into hydraulic systems, while their direct-acting mechanism allows for immediate response to pressure fluctuations. These valves are built with durable materials that resist corrosion and wear, ensuring longevity even under extreme conditions.

Technical studies highlight the innovative features of these valves. For example, the study titled Direct Acting Relief Valves and Real-Time Pressure Regulation emphasizes their ability to maintain consistent pressure levels, while Design Considerations for Selecting the Right Direct-Acting Sequence Valve explores the importance of material selection and flow dynamics.

| Study Title | Focus Area |

|---|---|

| Direct Acting Relief Valves and Real-Time Pressure Regulation | Relief Valves |

| The Role of Direct-Acting Sequence Valves in Industrial Automation | Direct-Acting Sequence Valves |

| Advanced features and innovations in Pilot Operated Directional Control Valves | Pilot Operated Directional Control Valves |

Common Industrial Applications

DIRECT OPERATED PRESSURE RELIEF VALVES play a critical role in various industries:

- Chemical Processing: They regulate pressure in reaction vessels, ensuring controlled chemical reactions.

- Oil and Gas: These valves manage pipeline pressures, preventing blowouts and environmental hazards.

- Water Treatment: They maintain optimal pressure in filtration systems, protecting sensitive components and ensuring efficient operation.

Their versatility makes them indispensable for industries that require precise pressure control to safeguard equipment and processes.

Advantages Over Other Valve Types

Compared to other valve types, DIRECT OPERATED PRESSURE RELIEF VALVES offer unique advantages. Their simple design ensures ease of maintenance and reduces the likelihood of operational errors. Unlike pilot-operated relief valves, which require complex setups, direct-operated valves provide immediate response to pressure changes, making them ideal for applications where speed and reliability are paramount.

| Valve Type | Advantages | Disadvantages |

|---|---|---|

| Spring – Loaded Relief Valve | Simple design, reliable, self – actuated | Sensitive to back pressure, less accurate at high pressures |

| Pilot – Operated Relief Valve | Precise set pressure, handles high pressures, less prone to chattering | Complex design, higher maintenance, increased cost |

| DIRECT OPERATED PRESSURE RELIEF VALVES | Immediate response, simple design, reliable performance | Limited to specific pressure ranges |

These valves excel in scenarios requiring rapid pressure adjustments, outperforming alternatives in terms of reliability and ease of use.

Importance of ISO 9001 Certification for DIRECT OPERATED PRESSURE RELIEF VALVES

Ensuring Consistent Product Quality

ISO 9001 certification plays a pivotal role in maintaining consistent product quality for direct operated pressure relief valves. Manufacturers adhere to stringent quality management systems, ensuring that every valve meets high standards for performance and reliability. This consistency minimizes variability, which is crucial for industrial applications where precision and safety are paramount.

Valves undergo rigorous inspections and tests to verify their quality under various conditions. These include dimensional checks, pressure tests, and sealing evaluations. Such measures ensure that the valves perform reliably, even in demanding environments. Proper selection and maintenance of control valves further enhance manufacturing processes, reducing waste and improving customer satisfaction.

Consistent product quality is not just a benchmark; it is a necessity for industries relying on fluid systems. Variability can lead to operational inefficiencies, increased costs, and potential safety hazards.

Compliance with International Standards

ISO 9001 certification signifies compliance with international standards, ensuring that direct operated pressure relief valves meet global benchmarks for quality and safety. Manufacturers provide detailed information about raw materials and production processes, preventing quality issues and ensuring adherence to industry protocols.

These valves are tested against recognized standards such as API 598, API 527, and ASME B16.34. For example:

| Applicable Standard | Valve Type and Test Procedure |

|---|---|

| API 598 | Inspection and testing of cast iron and steel valves, including cryogenic valves. |

| API 527 and ASME PTC 25 | Pressure relief valve testing. |

| ISA S-75 and ISO 5208 | Hydrostatic testing of control valves. |

Compliance with these standards ensures that the valves operate safely and efficiently, preventing leaks and safeguarding personnel and the environment.

Building Trust Through Certified Manufacturing Processes

ISO 9001 certification builds trust among customers and stakeholders by demonstrating a commitment to quality management. Certified manufacturers focus on reducing defects, improving customer experience, and enhancing process reliability. Performance metrics validate these efforts:

| Quality Objective | Corresponding KPI |

|---|---|

| Reduce customer complaints by 20% within the next year. | Number of customer complaints per month. |

| Improve overall customer experience. | Net Promoter Score (NPS), percentage of satisfied customers. |

| Enhance process reliability and output. | On-time delivery rate, production cycle time. |

| Minimize defects and ensure product compliance. | Defect rate, percentage of returned products. |

| Strengthen supply chain reliability. | Supplier delivery accuracy, defect rates in supplied materials. |

Certified manufacturing processes instill confidence in the reliability of direct operated pressure relief valves. Customers can trust that these valves will perform as expected, ensuring operational safety and efficiency.

How to Choose a Supplier for DIRECT OPERATED PRESSURE RELIEF VALVES

Verifying ISO 9001 and Other Relevant Certifications

Selecting a supplier for DIRECT OPERATED PRESSURE RELIEF VALVES requires careful verification of certifications. Suppliers must comply with industry standards and hold certifications such as ISO 9001 for Quality Management Systems and ISO 14001 for Environmental Management Systems. These certifications confirm adherence to rigorous quality control procedures and ensure the supplier’s commitment to delivering reliable products.

Statistical studies highlight the importance of certification in improving product reliability. Analysis of over 80,000 Safety Instrumented Function designs reveals that nearly 70% of the average probability of failure on demand (PFDavg) stems from the Final Element. Suppliers with robust certification processes significantly lower PFDavg, enhancing product reliability and reducing lifecycle costs.

Assessing Customer Reviews and Industry Reputation

Customer reviews and industry reputation provide valuable insights into a supplier’s reliability and performance. Positive reviews often indicate consistent product quality, timely delivery, and responsive customer service. Industry reputation reflects the supplier’s ability to meet client expectations and adapt to evolving market demands.

Buyers should prioritize suppliers with a proven track record in the valves market. Companies with strong reputations often invest in advanced manufacturing technologies and maintain high standards for quality assurance. This ensures that their products, including DIRECT OPERATED PRESSURE RELIEF VALVES, meet the stringent requirements of industrial applications.

Evaluating After-Sales Support and Warranty Policies

Comprehensive after-sales support and warranty policies are essential for maximizing the efficiency and longevity of valves. Leading suppliers offer services such as predictive maintenance solutions, on-site repairs, and spare parts management. Digital valve monitoring systems, provided by companies like KSB SE & Co. KGaA, deliver real-time diagnostics, reducing unexpected failures.

Technical assistance, training, and detailed documentation further enhance the value of after-sales support. Access to expert engineers for troubleshooting complex challenges ensures uninterrupted operations. Buyers should evaluate warranty terms to confirm coverage for defects and performance issues, safeguarding their investment in high-quality valves.

Bulk ordering ISO 9001 certified direct operated pressure relief valves offers significant advantages. Businesses benefit from cost savings, streamlined logistics, and reliable inventory management. Certified valves ensure consistent quality and operational safety. Choosing a trusted supplier enhances long-term performance. Industrial buyers should explore bulk purchasing to optimize efficiency and meet their operational demands.

FAQ

1. What are the benefits of choosing ISO 9001 certified valves for industrial applications?

ISO 9001 certified valves ensure consistent quality, reliability, and compliance with international standards. They minimize operational risks and enhance safety in demanding industrial environments.

2. How does bulk ordering improve cost efficiency for businesses?

Bulk ordering reduces per-unit costs, streamlines procurement processes, and lowers administrative expenses. It also ensures uninterrupted operations by maintaining a steady supply of essential components.

3. What factors should buyers consider when selecting a valve supplier?

Buyers should verify ISO 9001 certification, assess customer reviews, and evaluate after-sales support. These factors ensure product reliability, timely delivery, and long-term operational efficiency.