Ningbo Hanshang proudly introduces custom 3 Way Hydraulic Diverter Valves. These valves redefine control and efficiency in construction machinery. They empower manufacturers with unparalleled precision and adaptability for their equipment. The global construction machinery market shows strong growth, projected to reach an inspiring $487.92 billion by 2029. This innovation gives the industry a critical advantage.

Ningbo Hanshang proudly introduces custom 3 Way Hydraulic Diverter Valves. These valves redefine control and efficiency in construction machinery. They empower manufacturers with unparalleled precision and adaptability for their equipment. The global construction machinery market shows strong growth, projected to reach an inspiring $487.92 billion by 2029. This innovation gives the industry a critical advantage.

Key Takeaways

- Ningbo Hanshang offers new 3 Way Hydraulic Diverter Valves. These valves help construction machines work better and last longer.

- These special valves give machines precise control. They also help save energy and lower repair costs for manufacturers.

- Ningbo Hanshang has many years of experience. They make strong valves that work well in tough construction jobs.

Precision Control: The Advantage of Custom 3 Way Hydraulic Diverter Valves

Addressing Unique Demands in Construction Machinery

Addressing Unique Demands in Construction Machinery

Construction machinery manufacturers face many challenges with hydraulic control systems. Leaks often occur from wear, faulty fittings, or damaged seals, leading to fluid loss and reduced efficiency. Contamination from dirt, debris, or water severely damages components and affects performance. Overheating can result from high ambient temperatures, low fluid levels, or malfunctioning coolers. Air in the system causes sponginess and erratic behavior, impacting both efficiency and safety. Other issues include cavitation, corrosion, vibration, pressure spikes, seal failure, misalignment, and general wear and tear. Choosing the wrong hydraulic fluid also severely damages components and causes malfunctions.

Manufacturers also strive for increasing energy efficiency, improving reliability, and building smart components and systems. They aim to reduce size and weight, lessen environmental impact, and enhance energy storage and redeployment capabilities. Furthermore, recent supply chain interruptions have added financial pressure. Global events have caused shortages of critical components, including hydraulic systems. These shortages drive up production costs and slow equipment shipping, forcing manufacturers to carefully manage competitive pricing. Ningbo Hanshang understands these complex demands and offers solutions that empower manufacturers to overcome them.

Key Features of Ningbo Hanshang’s Custom 3 Way Hydraulic Diverter Valves

Ningbo Hanshang’s custom 3 Way Hydraulic Diverter Valves offer a powerful solution for these industry challenges. These valves serve as critical control elements in hydraulic systems. They feature one inlet port (P) and two outlet ports (A/B). This design precisely guides pressurized oil to two separate branches. It allows for switching control, enabling a single power source to drive different actuators. The valves achieve precise diversion, stable and durable operation, and strong adaptability.

Ningbo Hanshang, established in 1988, has a long history of innovation. The company believes leading innovation is the soul of its development. Pursuing excellence forms the cornerstone of its competition. Sharing achievements guides its cooperation. Forging a well-known brand in the hydraulic field remains its ultimate goal. The company’s 12,000-square-meter facility includes a 10,000-square-meter standard workshop. It houses over a hundred advanced machines, including CNC full-function lathes, machining centers, high-precision grinders, and honing machines. For quality assurance, Ningbo Hanshang developed a hydraulic valve test bench with Zhejiang University. This test bench features an integrated data acquisition system. It tests pressures up to 35MPa and flows up to 300L/Min. This allows for precise testing of dynamic, static, and fatigue life performance for various hydraulic valves. The valve body uses robust cast iron, and the spool is made from durable steel, ensuring longevity and reliability in harsh environments.

Tailored Solutions for Optimal System Performance

Ningbo Hanshang’s commitment to tailored solutions ensures optimal system performance for its clients. The company has an innovative R&D team. They use advanced 3D design software like PROE and integrate Solidcam. This guarantees high efficiency, reliability, and accuracy in product development and manufacturing. The company has continuously invested in production, management, and warehouse systems. It now operates an efficient management model. This model combines product R&D, sales orders, production management execution, data acquisition, and warehouse management. Recent automation in warehousing, along with WMS and WCS systems, earned the company a “digital workshop” designation in 2022.

These custom 3 Way Hydraulic Diverter Valves benefit various sectors. In manufacturing, they provide consistency, reliability, and improved productivity in complex hydraulic systems. The construction industry requires robust and precise flow control, making these valves ideal for synchronized operations and high-pressure conditions. Agriculture benefits from equal flow delivery to multiple circuits, ensuring harmony, efficiency, and reduced wear and tear. The energy sector demands valves that withstand extreme conditions, relying on durable, high-pressure-rated designs for safety and performance. Rotary diverter valves are crucial for hydraulic systems in tractors and other heavy machinery. They enable control of fluid flow to various hydraulic implements like loaders, plows, and cultivators. These valves handle high-pressure hydraulic fluids and extreme temperatures, ensuring efficient and effective operation. Ningbo Hanshang holds ISO9001-2015 quality management system certification and CE certification for its full range of hydraulic valves exported to Europe. This ensures stable and reliable hydraulic products for customers. Ningbo Hanshang adheres to the principle that product quality is the core of enterprise development and customers come first. Its industrial hydraulic valves, mobile machinery hydraulic valves, and threaded cartridge valves enjoy high market reputation. They sell well across China and export to over 30 countries and regions worldwide. Ningbo Hanshang aims to forge a well-known brand in the hydraulic field. It invites all friends and customers, new and old, to work together in the hydraulic field and create brilliance.

Elevating Performance: Benefits for Construction Machinery Manufacturers

Enhancing Operational Efficiency and Equipment Reliability

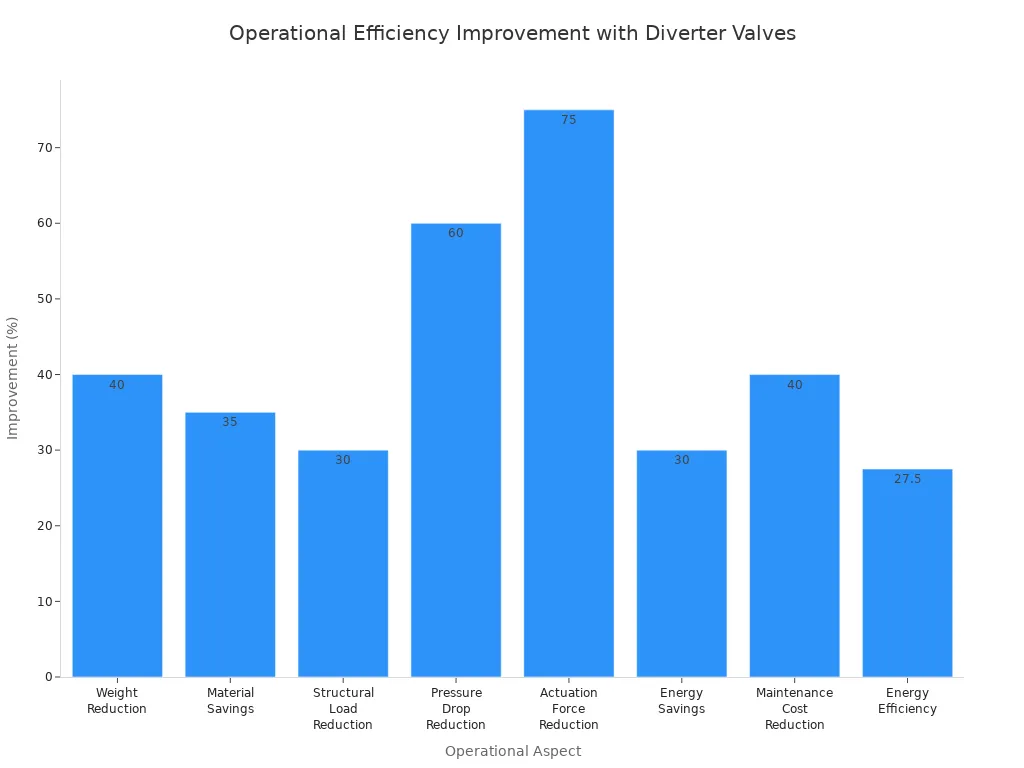

Ningbo Hanshang’s custom hydraulic solutions empower construction machinery manufacturers to reach new heights in operational efficiency and equipment reliability. These advanced valves transform how machinery performs, ensuring every operation runs smoothly and effectively. Manufacturers can achieve remarkable improvements across various operational aspects.

| Operational Aspect | Quantifiable Improvement |

|---|---|

| Weight Reduction | 40% |

| Material Savings | Up to 35% |

| Installation Efficiency | 50% less lifting equipment |

| Structural Load Reduction | Approximately 30% |

| Pressure Drop Reduction | 60% |

| Actuation Force Reduction | 75% |

| Switching Time | ≤0.5 seconds |

| Energy Savings | Up to 30% |

| System Uptime | 99.9% availability |

| Maintenance Cost Reduction | Up to 40% |

| Energy Efficiency | 20-35% |

These impressive figures highlight the transformative power of Ningbo Hanshang’s engineering. The valves significantly reduce weight and material usage, leading to lighter, more agile machinery. Installation becomes faster and easier, requiring less lifting equipment. Operators experience smoother control with reduced actuation force and rapid switching times. This translates into substantial energy savings and a remarkable 99.9% system uptime.

The reliability of equipment also sees a dramatic boost. Ningbo Hanshang’s valves have proven their endurance. They handle over 2 million tons of paste without requiring maintenance. This exceptional durability directly contributes to reduced system downtime and lower maintenance needs. Manufacturers can confidently offer equipment that performs consistently, day after day, even under the most demanding conditions. This reliability builds trust and strengthens a brand’s reputation.

Achieving Cost Savings and Faster Market Entry

Embracing Ningbo Hanshang’s custom hydraulic solutions opens doors to significant cost savings and accelerates market entry for construction machinery manufacturers. The efficiency gains directly translate into financial benefits. Reduced energy consumption lowers operational costs for end-users, making equipment more attractive in the market. The decrease in maintenance requirements further cuts expenses, freeing up resources for innovation and growth.

Manufacturers also benefit from streamlined production processes. The custom nature of these valves means they integrate seamlessly into existing designs, minimizing redesign efforts and associated costs. This efficiency in development and manufacturing allows companies to bring new or updated machinery to market much faster. A quicker market entry provides a crucial competitive edge, capturing opportunities and responding to industry demands with agility. By optimizing every stage from design to deployment, Ningbo Hanshang helps manufacturers achieve greater profitability and sustained success.

Robust Design for Harsh Construction Environments

Construction environments are notoriously tough, demanding components that can withstand extreme challenges. Ningbo Hanshang designs its custom valves with this reality in mind. They build each valve to endure the most severe conditions, ensuring unwavering performance and longevity.

The valves bravely face:

- Extreme wear: Abrasive particles, high fluid velocities, and cavitation (the formation and collapse of vapor bubbles) constantly challenge hydraulic systems. Ningbo Hanshang’s valves resist these forces.

- High temperatures: Elevated temperatures degrade elastomeric seals, break down hydraulic fluids, and alter valve material properties. The robust design protects against these damaging effects.

- Synergistic effect of wear and high temperatures: High temperatures make materials more vulnerable to wear, and friction from wear creates localized hot spots. Ningbo Hanshang’s valves combat this combined assault.

- Harsh conditions in industrial and construction machinery: Heavy excavators and large cranes operate in brutal settings. These valves thrive in such demanding applications.

Ningbo Hanshang reinforces this commitment to durability through rigorous quality standards and advanced treatments. The company holds ISO9001-2015 quality management system certification. Its full range of export valves also carries CE certification, confirming compliance with European safety, health, and environmental protection requirements. Furthermore, specific series, like the HVC6, feature phosphating surface treatment for enhanced corrosion resistance. The valves also maintain high oil cleanliness standards, meeting NAS1638 Grade 9 and ISO4406 20/18/15 levels. These certifications and design features assure manufacturers of a product that performs reliably, even when pushed to its limits. They provide the confidence needed to build machinery that excels in any construction challenge.

Ningbo Hanshang: A Legacy of Innovation in Hydraulic Systems

Decades of Expertise in Hydraulic Valve Manufacturing

Ningbo Hanshang has built a remarkable legacy in hydraulic systems. The company, established in 1988, stands as a leading manufacturer of hydraulic valves and systems. Hanshang Hydraulic actively engages in the research, development, and manufacturing of these critical components. Their product line includes CETOP industrial hydraulic valves, mobile hydraulic valves, and cartridge valves. These essential valves serve diverse industrial applications. They support metallurgical, energy, environmental, plastic, and rubber manufacturing. Mobile applications also benefit, including municipal, construction, agriculture, mining, and marine equipment. This deep experience ensures reliable solutions for every client.

Advanced R&D and Quality Assurance for 3 Way Hydraulic Diverter Valves

Innovation drives Ningbo Hanshang’s progress. The company invests heavily in advanced R&D and rigorous quality assurance. They utilize world-class 3D design software like PROE and integrate Solidcam. This ensures high efficiency, reliability, and accuracy in product development. For example, their custom 3 Way Hydraulic Diverter Valves undergo extensive testing. A specialized test bench, developed with Zhejiang University, precisely measures dynamic, static, and fatigue life. This commitment to excellence earned the company a “digital workshop” designation in 2022. ISO9001:2000 Quality Management System and CE Mark certifications further validate their dedication to superior quality.

Partnering for Success: Customer-Centric Approach and Global Reach

Ningbo Hanshang champions a customer-centric approach, fostering success through strong partnerships. The company extends its reach globally, ensuring support for clients worldwide. Hanshang Hydraulics US operates as a dedicated distributor within the Continental USA. This distributor offers free and fast shipping, USA inventory, and free returns. Ningbo Hanshang’s main office is located at No. 118 Qiancheng Road, Zhenhai, Ningbo, Zhejiang province, China. Their website provides language options in English, French, German, Portuguese, and Spanish. This global presence and commitment to service empower customers everywhere.

Ningbo Hanshang’s introduction of custom 3 Way Hydraulic Diverter Valves marks a significant advancement for construction machinery manufacturers. These valves deliver tailored, high-performance solutions. They meet the industry’s rigorous demands with precision and reliability. This initiative reinforces Ningbo Hanshang’s commitment to innovation. It also supports the evolving needs of its global clientele.

FAQ

What are 3 Way Hydraulic Diverter Valves?

These specialized valves precisely guide hydraulic fluid. They direct oil from one inlet to two separate outlets. This enables efficient control and switching between different machine functions, optimizing performance.

How do these valves enhance construction machinery?

They boost operational efficiency and equipment reliability. Manufacturers achieve precise control, reducing downtime and maintenance needs. This leads to superior performance in demanding environments, inspiring confidence.

Why should manufacturers choose Ningbo Hanshang’s valves?

Ningbo Hanshang offers decades of expertise and cutting-edge R&D. Their custom solutions ensure optimal system performance and robust design. They provide reliable, high-quality hydraulic components, empowering success.