Choosing the appropriate LPS PRESSURE SWITCH is crucial for industrial hydraulic and pneumatic systems. It directly impacts operational efficiency. Furthermore, proper selection significantly enhances system safety. An incorrect choice can lead to costly downtime and serious operational risks.

Choosing the appropriate LPS PRESSURE SWITCH is crucial for industrial hydraulic and pneumatic systems. It directly impacts operational efficiency. Furthermore, proper selection significantly enhances system safety. An incorrect choice can lead to costly downtime and serious operational risks.

Key Takeaways

- Choosing the right LPS pressure switch is important. It makes sure industrial systems work well and safely.

- Consider pressure range, what the switch touches, and electrical needs. Also, think about where the switch will be used.

- Work with good suppliers like Hanshang Hydraulic. They offer quality products and help you choose the best switch.

Understanding the LPS PRESSURE SWITCH

What is an LPS PRESSURE SWITCH?

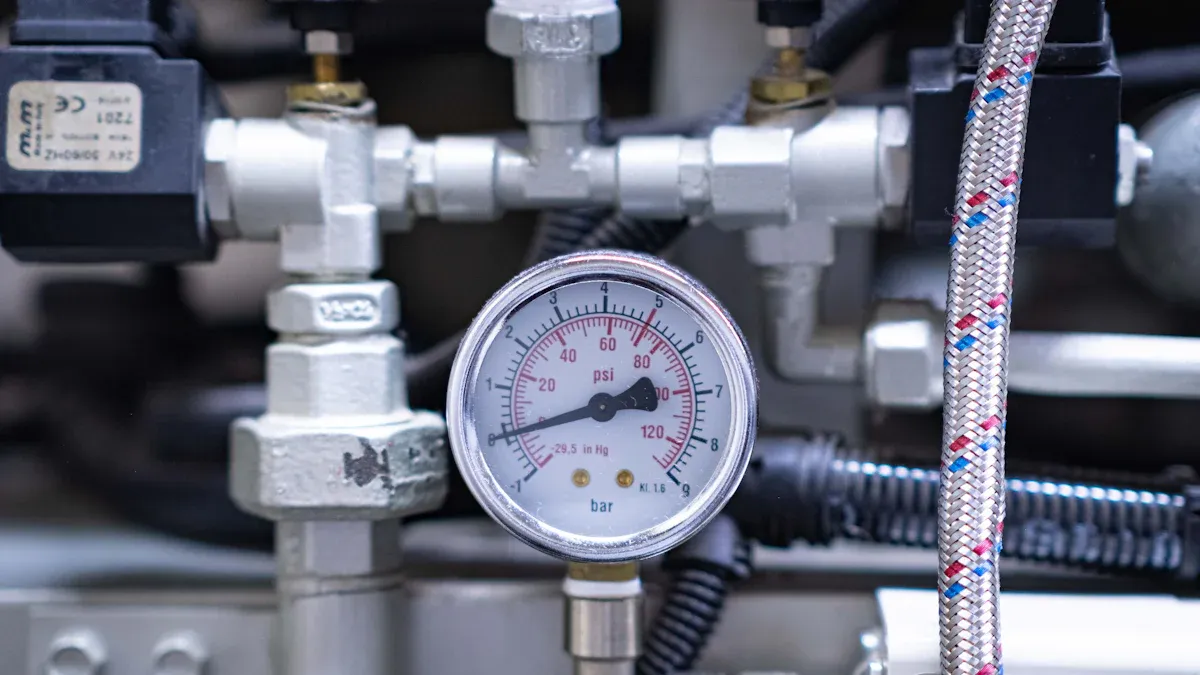

An LPS PRESSURE SWITCH is a device. It monitors pressure within a system. It then sends an electrical signal when pressure reaches a specific setpoint. These switches often use a plunger-type mechanism. A micro switch then activates. This action controls hydraulic components. It turns them on or off. This makes actuators start or stop. These switches offer a wide pressure control range. They are also easy to operate and simple to install.

The Fundamental Role of LPS PRESSURE SWITCHES in Industrial Systems

LPS PRESSURE SWITCHES play a vital role in industrial operations. They ensure the safe and efficient functioning of hydraulic and pneumatic systems. These devices provide critical feedback. They protect equipment from overpressure or underpressure conditions. This prevents damage and costly downtime. They also enable automation. Systems can respond to pressure changes automatically. This maintains optimal performance. Their presence is essential for system control and reliability.

Hanshang Hydraulic’s Contribution to LPS PRESSURE SWITCH Technology

Hanshang Hydraulic has significantly advanced LPS PRESSURE SWITCH technology. The company began in 1988. It focuses on innovation and excellence. Hanshang Hydraulic designs and manufactures hydraulic valves and systems. They use advanced R&D. Their team employs 3D design software like PROE. This ensures high efficiency and accuracy. Hanshang Hydraulic’s testing facilities are state-of-the-art. They test pressures up to 35MPa and flows up to 300 L/Min. This guarantees product quality and reliability. Their commitment to quality is evident. They hold ISO9001-2015 certification. They also have CE certification for European exports. These efforts ensure Hanshang Hydraulic delivers stable and reliable products.

Key Selection Criteria for Your 2025 LPS PRESSURE SWITCH

Selecting the right pressure switch requires careful consideration of several factors. These factors ensure optimal performance, safety, and longevity within industrial hydraulic and pneumatic systems. Engineers must evaluate each criterion thoroughly.

Pressure Range and Setpoint Accuracy for LPS PRESSURE SWITCHES

The pressure range defines the minimum and maximum pressure values a switch can reliably monitor. It is crucial to choose a switch whose operating range comfortably covers the system’s normal and peak pressures. Setpoint accuracy refers to how precisely the switch activates at a predetermined pressure level. High accuracy prevents false triggers and ensures timely system responses. Hysteresis, the difference between the activation and deactivation pressure, also plays a role. A suitable hysteresis prevents rapid cycling of the switch, which extends its lifespan. Repeatability ensures the switch consistently activates at the same pressure point over many cycles.

Media Compatibility for LPS PRESSURE SWITCH Applications

The materials used in the pressure switch must be compatible with the fluid or gas it monitors. Incompatible materials can lead to corrosion, leaks, or premature failure. Common media include hydraulic oil, compressed air, water, and various chemicals. Manufacturers typically offer switches made from materials like stainless steel, brass, or specific plastics and elastomers. Always verify the switch’s material specifications against the system’s media to prevent adverse reactions.

Electrical Ratings and Circuitry for LPS PRESSURE SWITCH Integration

Electrical ratings specify the maximum voltage and current the switch contacts can safely handle. These ratings must match the control circuit’s requirements. Exceeding them can damage the switch or the connected equipment. Circuitry options include Normally Open (NO) and Normally Closed (NC) contacts. An NO contact closes when the set pressure is reached, while an NC contact opens. The choice depends on the desired system behavior. Connection types, such as screw terminals or quick-disconnect connectors, also impact ease of installation and maintenance.

Environmental Operating Conditions for LPS PRESSURE SWITCH Durability

The operating environment significantly affects a pressure switch’s durability and performance. Consider factors like ambient temperature, humidity, vibration, and shock. Extreme temperatures can degrade internal components. High humidity may lead to corrosion or electrical shorts. Excessive vibration or shock can cause mechanical wear or false readings. Ingress Protection (IP) ratings indicate the switch’s resistance to dust and water. For example, an IP67 rating means the switch is dust-tight and can withstand temporary immersion in water. Selecting a switch with appropriate environmental protection ensures reliable operation in harsh industrial settings.

Required Certifications and Standards for LPS PRESSURE SWITCH Compliance

Compliance with relevant industry certifications and standards guarantees a pressure switch meets specific safety and performance benchmarks. For products sold in Europe, CE marking is often mandatory. UL listing is a common requirement for North American markets, indicating compliance with safety standards. For hazardous or explosive environments, certifications like ATEX are essential. These certifications assure users of the product’s quality, reliability, and adherence to regulatory requirements. Always confirm the necessary certifications for your specific application and region.

Types of LPS PRESSURE SWITCHES

Choosing the correct LPS PRESSURE SWITCH type is essential. Different applications require different technologies. Understanding these types helps in making an informed decision.

Mechanical LPS PRESSURE SWITCHES

Mechanical pressure switches operate using physical movement. A pressure change causes a diaphragm, bellows, or piston to move. This movement then actuates a micro switch. They are simple in design. These switches do not require external power for their sensing function. They directly convert pressure into a mechanical action. This action opens or closes an electrical contact. Their construction often makes them robust.

Electronic LPS PRESSURE SWITCHES

Electronic pressure switches use a pressure transducer. This transducer converts pressure into an electrical signal. A microprocessor then processes this signal. The switch activates when the signal reaches a set point. These switches offer digital displays and programmable features. They often provide analog outputs for continuous monitoring. Electronic switches typically require a power supply. They deliver high accuracy and flexibility.

Advantages and Disadvantages of Each LPS PRESSURE SWITCH Type

Each type offers distinct benefits and drawbacks. Mechanical switches are generally more cost-effective. They are also very durable in harsh environments. Their simple design means fewer points of failure. However, they offer lower accuracy. Their set points are less precise. Electronic switches provide superior accuracy. They allow for easy adjustment of set points. Many models include advanced diagnostic capabilities. They can integrate into complex control systems. Yet, electronic switches are often more expensive. They can be more sensitive to electrical noise or extreme temperatures.

LPS PRESSURE SWITCH Applications in Industrial Systems

LPS PRESSURE SWITCHES are essential components across many industrial sectors. They ensure the safe and efficient operation of machinery. These devices provide critical control and monitoring functions.

LPS PRESSURE SWITCHES are essential components across many industrial sectors. They ensure the safe and efficient operation of machinery. These devices provide critical control and monitoring functions.

LPS PRESSURE SWITCHES in Hydraulic Systems

Hydraulic systems rely on fluid pressure to transmit power. These switches monitor this pressure. They can activate or deactivate pumps. This maintains desired pressure levels. For example, a switch might signal a pump to start when pressure drops too low. It can also trigger a safety valve. This prevents overpressure conditions. This protects expensive hydraulic components from damage. They ensure smooth and controlled movement of hydraulic cylinders and motors.

LPS PRESSURE SWITCHES in Pneumatic Systems

Pneumatic systems use compressed air for power. These switches play a similar role here. They monitor air pressure within the system. They control air compressors. This ensures a consistent air supply. A switch might detect low air pressure. It then signals the compressor to refill the tank. They also ensure proper pressure for pneumatic tools. This prevents equipment malfunction. These switches contribute to energy efficiency by managing compressor cycles.

Real-World Industrial Examples of LPS PRESSURE SWITCH Use

Many industries use these switches daily. In manufacturing, they control clamping mechanisms on assembly lines. They ensure parts are held securely. In heavy machinery, such as excavators, they monitor hydraulic pressure for boom movements. This provides precise control. Food processing plants use them to regulate pressure in cleaning systems. This ensures proper sanitation. They also appear in automated gate systems. Here, they detect pressure changes. This indicates an obstruction. This wide range of applications highlights their versatility and importance.

Future Trends for the LPS PRESSURE SWITCH in 2025

Smart Features and IoT Integration for LPS PRESSURE SWITCHES

Pressure switches will become smarter. They will connect to the Internet of Things (IoT). This allows for remote monitoring. Operators can check system pressure from anywhere. Switches will send data to central control systems. This integration enables better automation. Systems can react to pressure changes instantly. This improves efficiency and reduces human intervention. Smart switches will play a key role in connected industrial environments.

Enhanced Durability and Miniaturization of LPS PRESSURE SWITCHES

Manufacturers will focus on making pressure switches tougher. New materials will resist harsh conditions. Better sealing technologies will protect internal components. This increases their lifespan. Switches will also become smaller. This allows for installation in tight spaces. Miniaturization helps integrate them into compact machinery. These advancements improve reliability and versatility in various applications.

Predictive Maintenance Capabilities for LPS PRESSURE SWITCH Systems

Future pressure switches will support predictive maintenance. They will collect data on their own performance. This data helps identify potential failures before they happen. Systems can then schedule maintenance proactively. This reduces unexpected downtime. It also lowers repair costs. Predictive maintenance capabilities will make industrial operations more efficient and reliable.

Troubleshooting Common LPS PRESSURE SWITCH Issues

Identifying Malfunctions in Your LPS PRESSURE SWITCH

Operators often notice several signs when a pressure switch malfunctions. The system may fail to respond to pressure changes. It might operate inconsistently. Sometimes, the equipment cycles on and off too frequently. Visible damage to the switch housing or wiring also indicates a problem. A system alarm related to pressure could point to a faulty switch. Observing these symptoms helps pinpoint the issue.

Basic Diagnostic Steps for LPS PRESSURE SWITCH Problems

When a pressure switch seems faulty, follow basic diagnostic steps. First, check all electrical connections. Ensure they are secure and free from corrosion. Verify the power supply to the switch. Confirm it receives the correct voltage. Next, inspect the pressure lines connected to the switch. Look for blockages or leaks. Test the switch’s setpoint if possible. Compare it to the actual system pressure. A multimeter can check continuity across the switch contacts. This determines if the switch opens or closes correctly.

When to Replace or Repair Your LPS PRESSURE SWITCH

Deciding whether to replace or repair a pressure switch depends on several factors. Consider the age of the switch. Older switches often have worn internal components. Repairing them might not be cost-effective. If the damage is minor, like a loose wire, a repair is feasible. However, significant internal damage or a cracked housing usually requires replacement. Evaluate the cost of a new switch versus repair parts and labor. For critical applications, replacing a questionable switch prevents future downtime. Always prioritize safety and system reliability.

Making Your Optimal LPS PRESSURE SWITCH Choice

Selecting the ideal pressure switch requires a strategic approach. Engineers must carefully evaluate various factors. This ensures the chosen device integrates seamlessly and performs reliably within the industrial system.

Matching the LPS PRESSURE SWITCH to System Requirements

System requirements form the foundation of any selection process. Engineers must precisely define the operating pressure range. This includes both normal working pressures and potential peak pressures. The switch’s setpoint accuracy must align with the application’s control precision needs. For instance, a system requiring tight pressure regulation demands a switch with minimal hysteresis and high repeatability.

Consider the media flowing through the system. Hydraulic oil, compressed air, water, or corrosive chemicals each require specific material compatibility. The switch’s wetted parts must resist degradation from the media. Electrical specifications are equally important. The switch’s voltage and current ratings must match the control circuit. The choice between Normally Open (NO) and Normally Closed (NC) contacts depends on the desired system logic. Environmental conditions also play a critical role. Temperature extremes, humidity, vibration, and potential exposure to dust or water necessitate a switch with appropriate environmental protection, such as a suitable IP rating.

Considering Total Cost of Ownership for Your LPS PRESSURE SWITCH

The initial purchase price of a pressure switch represents only one part of its total cost. Engineers must consider the total cost of ownership (TCO). This includes installation expenses, ongoing maintenance, and potential costs from system downtime. A cheaper switch might offer a lower upfront cost. However, it could lead to higher TCO if it fails frequently or requires extensive calibration.

Evaluate the switch’s expected lifespan and warranty. A durable switch reduces replacement frequency. This saves both material and labor costs. Consider the energy consumption, especially for electronic models. While often minimal, it contributes to long-term operational expenses. Investing in a high-quality, reliable switch often proves more economical over the system’s operational life. It minimizes disruptions and ensures consistent performance.

Partnering with Reputable LPS PRESSURE SWITCH Suppliers like Hanshang Hydraulic

Choosing the right supplier is as crucial as selecting the right switch. A reputable supplier offers more than just a product. They provide expertise, support, and assurance of quality. Hanshang Hydraulic, for example, stands as a testament to such a partnership. The company, established in 1988, has built a strong reputation for innovation and excellence in hydraulic components.

When evaluating suppliers, look for several key indicators:

- Reliability and Durability: A reputable supplier offers pressure switches known for their long operational life and consistent performance in demanding industrial environments. Hanshang Hydraulic’s extensive testing facilities, capable of pressures up to 35MPa and flows up to 300 L/Min, ensure product robustness.

- Accuracy and Repeatability: The switches should provide precise pressure readings and consistent activation/deactivation points. This is crucial for process control and safety.

- Certifications and Standards Compliance: Look for suppliers whose products meet relevant industry standards. These include UL, CE, and ATEX. Quality management certifications like ISO 9001 are also important. Hanshang Hydraulic holds ISO9001-2015 certification and CE certification for its hydraulic valves, demonstrating its commitment to global standards.

- Technical Support and Expertise: A strong supplier provides comprehensive technical assistance. This includes product selection, installation guidance, and troubleshooting. Hanshang Hydraulic’s innovative R&D team, utilizing advanced 3D design software like PROE, offers deep product knowledge.

- Customization Options: The ability to offer switches with specific pressure ranges, materials, electrical connections, and housing types meets unique application requirements.

- Warranty and After-Sales Service: A reputable supplier stands behind their products with a clear warranty policy. They also offer efficient after-sales support for maintenance and repairs.

- Positive Customer Reviews and References: Feedback from other customers indicates a supplier’s reputation for product quality and service. Hanshang Hydraulic’s products are sold in over 30 countries, reflecting widespread customer satisfaction.

Hanshang Hydraulic’s continuous investment in manufacturing and management, including a digitized workshop and automated warehousing systems (WMS, WCS), further underscores their commitment to delivering stable and reliable hydraulic products. Partnering with such a company ensures access to high-quality components and expert support, contributing significantly to the success and longevity of industrial systems.

Choosing the correct pressure switch is vital. It ensures system efficiency and safety. Informed decisions prevent costly downtime. They also extend equipment longevity. Partnering with a reliable supplier like Hanshang Hydraulic guarantees quality products. They provide expert support for all industrial needs.

FAQ

What is the primary function of an LPS Pressure Switch?

An LPS Pressure Switch monitors system pressure. It sends an electrical signal when pressure reaches a set point. This controls hydraulic or pneumatic components.

How do mechanical and electronic LPS Pressure Switches differ?

Mechanical switches use physical movement to activate. Electronic switches use a transducer and microprocessor. Electronic models offer higher accuracy and programmability.

Why is media compatibility important for an LPS Pressure Switch?

Media compatibility prevents corrosion and leaks. It ensures the switch materials do not react with the system’s fluid or gas. This extends switch lifespan.