Hydraulic pilot-operated pressure relief valves are essential for regulating pressure effectively in hydraulic systems. These valves utilize pilot pressure to control the main valve, ensuring both safety and efficiency. Understanding the operation of these hydraulic valves is crucial for optimizing system performance. A proper knowledge of pilot-operated pressure relief valves enhances the overall reliability of hydraulic systems, making them a vital component in various applications.

Key Takeaways

- Hydraulic pilot-operated pressure relief valves regulate system pressure effectively, preventing overpressure and ensuring safety in hydraulic systems.

- These valves offer superior performance in high-pressure applications, providing precise pressure control and reducing operational costs over time.

- Common applications include manufacturing, construction, oil and gas, and automotive industries, where they enhance efficiency and reliability.

Definition and Comparison of HYDRAULIC PILOT OPERATED PRESSURE RELIEF VALVES

What Are HYDRAULIC PILOT OPERATED PRESSURE RELIEF VALVES?

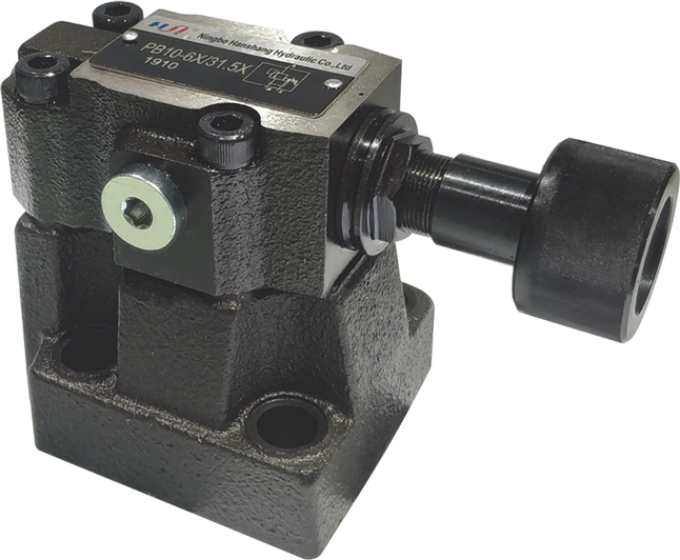

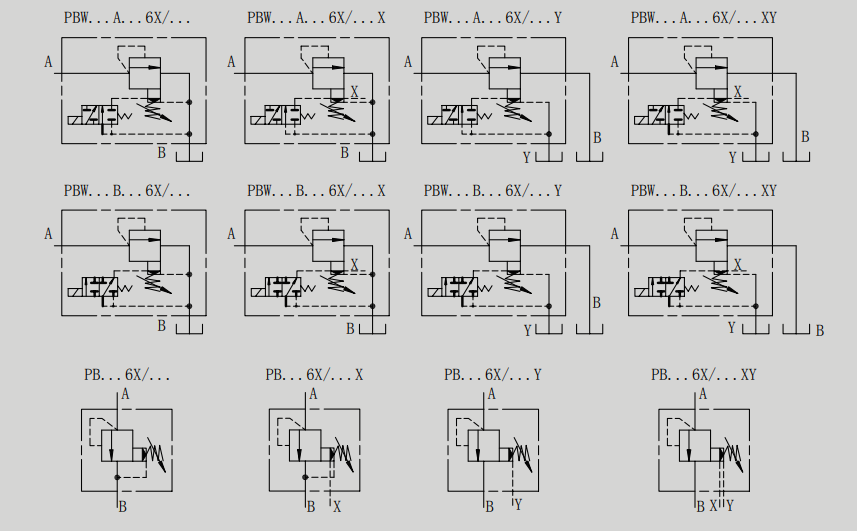

Hydraulic pilot-operated pressure relief valves (POSRVs) are specialized devices designed to manage pressure within hydraulic systems. According to leading engineering standards, a pilot-operated pressure relief valve operates based on a remote command from a pilot valve connected to the upstream system pressure. This valve utilizes an auxiliary pressure-sensing device, known as the pilot, to control the main valve. When the system pressure reaches a predetermined set point, the pilot activates the main valve to open, allowing for precise pressure control. This design enables the valve to handle higher-pressure systems effectively.

Comparison to Other Pressure Relief Valves

When comparing hydraulic pilot-operated pressure relief valves to other types, several key differences emerge.

- Operation Mechanism:

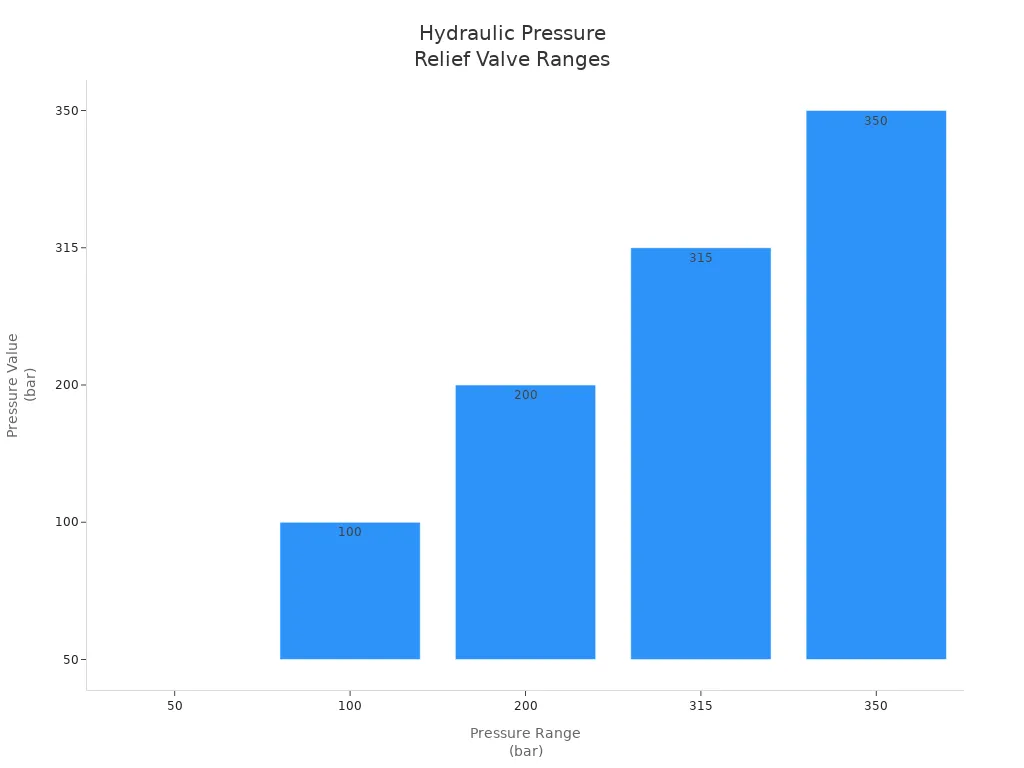

- Hydraulic pilot-operated pressure relief valves function in two stages. They utilize a pilot stage to control the main valve, which opens only when system pressure reaches 90% of full pressure. This design maintains efficiency, especially in high-pressure and high-volume applications.

- In contrast, direct-acting pressure relief valves feature a simpler design. They consist of a poppet or ball that directly responds to system pressure. When pressure exceeds the spring setting, the valve allows fluid to bypass to the reservoir.

- Response Time: The response times of these valves also differ significantly.

Valve Type Response Time Key Features Direct-acting pressure relief Very rapid Simpler design with one moving part, minimizes pressure spikes Pilot-operated pressure relief Slower More complex design with a pilot stage, better pressure regulation but slower response - Cost Considerations:

- Pilot-operated valves typically have a higher initial cost due to their complex design. However, they may incur lower long-term operational costs. This reduction stems from decreased wear and tear and improved sealing, leading to a longer lifespan.

- Conversely, direct-acting pressure relief valves are more cost-effective for initial purchases. They may, however, require more frequent maintenance and replacements, resulting in higher operational costs over time.

- Industry Standards: Various industry standards apply to hydraulic pilot-operated pressure relief valves, ensuring their reliability and safety.

Standard/Certification Application/Details ASME Section VIII Compliance for pressure vessels API 520/526 Guidelines for refinery applications PED 2014/68/EU Standards for European markets NACE MR0175 Requirements for sour service in chemical plants NORSOK M-630 Compatibility for offshore applications 3A-sanitary Certifications for food/pharma sectors

Design Features and Operational Mechanisms of HYDRAULIC PILOT OPERATED PRESSURE RELIEF VALVES

Key Components of HYDRAULIC PILOT OPERATED VALVES

Hydraulic pilot-operated pressure relief valves consist of several critical components that work together to ensure effective pressure regulation. The main parts include:

- Pilot Valve: This component monitors system pressure and activates when the pressure exceeds a set threshold.

- Main Valve: The main valve opens to relieve excess pressure based on signals from the pilot valve.

- Diaphragm or Piston: This element responds to fluid flow changes, allowing for precise control of the main valve’s position.

How the Pilot Mechanism Works

The pilot mechanism plays a vital role in detecting and responding to changes in system pressure. When the pressure reaches a specific threshold, the pilot valve activates. This action triggers fluid flow that influences the diaphragm or piston in the main valve assembly. As a result, the main valve gradually opens to release excess pressure. Once the pressure stabilizes, the pilot valve closes, sealing off the flow. This process ensures that the hydraulic system maintains optimal pressure levels without oscillation.

Pressure Regulation Process in HYDRAULIC PILOT OPERATED PRESSURE RELIEF VALVES

The pressure regulation process involves several steps:

- The pilot valve continuously monitors system pressure.

- If the pressure exceeds the set point, the pilot valve reduces pressure on the main valve.

- This reduction allows the main valve to partially open, quickly relieving excess pressure.

- The control valve’s responsiveness ensures that the system maintains the desired pressure.

This systematic approach allows hydraulic pilot-operated pressure relief valves to manage pressures effectively across various applications, ensuring safety and efficiency.

Advantages and Applications of HYDRAULIC PILOT OPERATED PRESSURE RELIEF VALVES

Benefits of Using HYDRAULIC PILOT OPERATED Valves

Hydraulic pilot-operated pressure relief valves offer several operational advantages over traditional direct-acting pressure relief valves. These benefits include:

- Superior Performance at High-Pressure Applications: Pilot-operated relief valves (PORVs) excel in high-pressure environments. Their auxiliary pilot system ensures better accuracy and stability, making them ideal for demanding applications.

- Precise Pressure Control: PORVs maintain system pressures within required ranges with unrivaled precision. This capability prevents overpressure issues and enhances operational efficiency.

- Reduced Blowdown and Better Modulation: Modern designs of PORVs minimize blowdown, which leads to higher operating accuracy and improved system uptime.

These advantages contribute to the overall reliability and efficiency of hydraulic systems, making hydraulic pilot-operated pressure relief valves a preferred choice in various industries.

Common Applications in Industry

Hydraulic pilot-operated pressure relief valves find extensive use across multiple sectors. Their versatility allows them to adapt to various applications, including:

- Manufacturing: In manufacturing processes, these valves regulate pressure in hydraulic presses and injection molding machines, ensuring consistent performance and safety.

- Construction: Heavy machinery, such as excavators and cranes, relies on hydraulic systems for operation. Pilot-operated valves help maintain optimal pressure levels, preventing equipment failure.

- Oil and Gas: In the oil and gas industry, these valves manage pressure in drilling rigs and pipelines, safeguarding against hazardous overpressure situations.

- Automotive: Hydraulic systems in automotive assembly lines utilize pilot-operated valves to control pressure in robotic arms and other machinery, enhancing production efficiency.

The adaptability of hydraulic pilot-operated pressure relief valves makes them essential in maintaining safety and efficiency in these applications.

Case Studies of Effective Use of HYDRAULIC PILOT OPERATED PRESSURE RELIEF VALVES

Several documented case studies illustrate the effectiveness of hydraulic pilot-operated pressure relief valves in preventing system failures:

- A mathematical model analyzed pressure drop in pilot-operated pressure relief valves. Experimental tests compared theoretical results with actual performance, leading to improved valve characteristics.

- The implementation of a secondary safety relief valve prevented system pressure from exceeding safe limits. In failure scenarios, this secondary valve limited pressure, allowing for operational adjustments before critical failures occurred.

- A secondary relief valve, paired with a pressure sensor, mitigated risks associated with primary relief valve failure. This proactive measure ensured that system pressure only rose slightly above normal, allowing for timely maintenance intervention.

These case studies demonstrate how hydraulic pilot-operated pressure relief valves enhance system integrity and prevent catastrophic failures, underscoring their importance in hydraulic systems.

Hydraulic pilot-operated pressure relief valves play a vital role in maintaining system integrity and safety. They regulate pressure levels effectively, preventing damage from surges and ensuring optimal performance. Their unique design offers significant advantages over traditional valves, such as improved accuracy and reliability. A thorough understanding of these valves is essential for professionals working with hydraulic systems, especially as industry trends indicate a growing demand for efficient pressure control solutions.

| Factor | Description |

|---|---|

| Industrial Automation | Increasing automation in industries drives the demand for efficient pressure control systems. |

| Safety Regulations | Stringent safety regulations across sectors like oil & gas and manufacturing boost adoption. |

| Technological Advancements | Improvements in valve reliability and response time enhance market presence. |

| Global Exploration | Expanding oil & gas exploration activities create opportunities, particularly in Asia Pacific and the Middle East. |

FAQ

What is the primary function of hydraulic pilot-operated pressure relief valves?

Hydraulic pilot-operated pressure relief valves primarily regulate system pressure, preventing overpressure situations and ensuring safe operation.

How do pilot-operated valves differ from direct-acting valves?

Pilot-operated valves use a two-stage mechanism for better pressure control, while direct-acting valves respond immediately to pressure changes.

Can hydraulic pilot-operated pressure relief valves be used in all hydraulic systems?

Yes, these valves are versatile and suitable for various hydraulic systems, especially those requiring precise pressure regulation and high flow rates.