The HPLK hydraulic control one-way valve plays a crucial role in maintaining 24-hour stable operation for heavy machinery. This valve ensures efficient fluid control, which is vital for optimal performance. Additionally, the use of hydraulic valves, such as the HPLK, enhances reliability in demanding environments. Operators benefit from the valve’s ability to manage pressure effectively, especially when utilizing PILOT OPERATED CHECK VALVES for improved system efficiency.

Key Takeaways

- The HPLK valve ensures smooth fluid flow in one direction, preventing backflow and maintaining stable pressure in hydraulic systems.

- Operators benefit from the valve’s zero-leakage feature, which reduces downtime and enhances overall efficiency in heavy machinery.

- Using PILOT OPERATED CHECK VALVES alongside the HPLK valve improves safety and responsiveness, allowing for quick adjustments during operation.

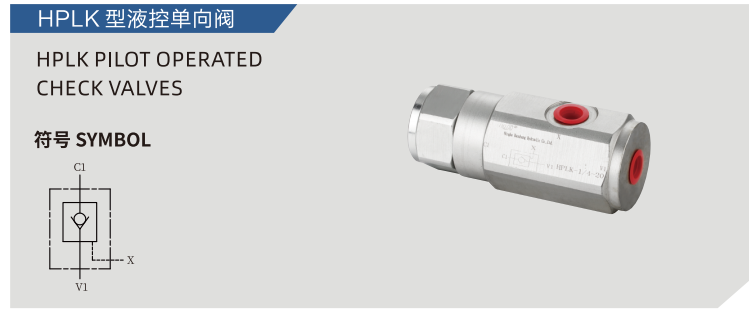

Overview of HPLK Hydraulic Control One-Way Valve

Design Features

The HPLK hydraulic control one-way valve boasts several key design features that enhance its performance in heavy machinery. First, the valve body is constructed from high-quality steel, ensuring durability and resistance to wear. The surface undergoes a white zinc plating process, which provides additional protection against corrosion.

Key specifications include:

- Maximum Flow Rate: 150 L/min

- Maximum Working Pressure: 31.5 MPa

- Oil Cleanliness Standards: NAS1638 Level 9 and ISO4406/18/15

These features contribute to the valve’s ability to operate efficiently under demanding conditions.

Functionality in Heavy Machinery

The HPLK valve functions as a critical component in hydraulic systems. It allows fluid to flow in one direction while preventing backflow, which is essential for maintaining pressure and ensuring system stability. When the pressure at port V1 reaches the spring setting, the valve core disengages from the seat, allowing fluid to flow freely from V1 to C1.

In normal operation, the valve remains closed from C1 to V1. However, when the pilot pressure at port X is sufficient, it activates the pilot piston, pushing the valve core away from the seat. This action permits fluid to flow from C1 back to V1 without leakage.

The design and functionality of the HPLK valve make it indispensable for operators seeking reliable and efficient hydraulic solutions in heavy machinery applications.

Mechanisms of Stability

Technical Specifications

The HPLK hydraulic control one-way valve features technical specifications that contribute significantly to its stability and performance in heavy machinery. Key specifications include:

- Maximum Flow Rate: 150 L/min

- Maximum Working Pressure: 31.5 MPa

- Oil Cleanliness Standards: NAS1638 Level 9 and ISO4406/18/15

These specifications ensure that the valve operates efficiently under high-pressure conditions. The robust design allows the valve to handle varying loads without compromising performance. The valve’s ability to maintain zero leakage during operation further enhances its reliability.

Performance Under Load

The performance of the HPLK valve under load is critical for ensuring continuous operation in demanding environments. When subjected to high pressure, the valve maintains its integrity and functionality. The design allows for smooth fluid flow, which is essential for the stability of hydraulic systems.

Operators often rely on PILOT OPERATED CHECK VALVES to enhance system efficiency. These valves work in conjunction with the HPLK valve to provide additional control over fluid dynamics. The pilot-operated mechanism ensures that the valve responds promptly to changes in pressure, allowing for quick adjustments during operation.

In real-world applications, the HPLK valve has demonstrated exceptional performance under load. It effectively manages pressure fluctuations, ensuring that heavy machinery operates smoothly. This capability minimizes downtime and maximizes productivity, making the HPLK valve a preferred choice for operators in various industries.

Case Studies of HPLK Valves

Application in Construction Equipment

The HPLK hydraulic control one-way valve finds extensive use in construction equipment. Operators rely on this valve for its ability to manage hydraulic fluid flow efficiently. For instance, in excavators, the HPLK valve ensures precise control of the boom and arm movements. This precision enhances the overall performance of the machinery, allowing for smoother operations and improved productivity.

Use in Mining Machinery

In mining machinery, the HPLK valve plays a vital role in maintaining operational stability. It supports hydraulic systems in equipment such as loaders and drills. The valve’s design allows it to withstand harsh conditions, including high pressure and heavy loads. This durability ensures that mining operations run continuously without interruptions, which is crucial for meeting production targets.

Performance Metrics and Results

Performance metrics highlight the effectiveness of the HPLK valve in various applications. Operators report significant improvements in efficiency and reliability. For example, machinery equipped with the HPLK valve experiences reduced downtime due to its zero-leakage feature. Additionally, operators note enhanced responsiveness to pressure changes, which contributes to safer and more efficient operations. Overall, the HPLK valve demonstrates exceptional performance across different heavy machinery applications, solidifying its reputation as a reliable hydraulic solution.

Benefits of Using HPLK Valves

Advantages for Operators

The HPLK hydraulic control one-way valve offers numerous advantages for operators in heavy machinery applications. First, the valve enhances operational efficiency. Its design allows for precise control of hydraulic fluid flow, which leads to improved performance in various tasks. Operators can expect smoother movements and quicker response times, particularly in equipment like excavators and loaders.

Another significant advantage is the valve’s reliability. The zero-leakage feature ensures that hydraulic systems maintain optimal pressure levels. This reliability minimizes the risk of unexpected downtime, allowing operators to focus on their work without worrying about equipment failure.

Additionally, the HPLK valve contributes to safety in operations. By preventing backflow and maintaining consistent pressure, the valve reduces the likelihood of accidents caused by hydraulic system failures. Operators can work with confidence, knowing that their equipment is equipped with a dependable hydraulic solution.

Maintenance Efficiency

Maintenance efficiency is another critical benefit of using HPLK valves. The robust construction and high-quality materials used in the valve’s design result in a longer lifespan. Operators experience fewer maintenance requirements, which translates to lower operational costs over time.

Furthermore, the straightforward design of the HPLK valve simplifies maintenance procedures. Operators can quickly access and service the valve, reducing the time spent on repairs. This ease of maintenance allows for more efficient scheduling of service activities, ensuring that machinery remains operational with minimal interruptions.

Incorporating PILOT OPERATED CHECK VALVES alongside the HPLK valve further enhances maintenance efficiency. These valves work together to optimize fluid dynamics, reducing wear and tear on the hydraulic system. As a result, operators can expect extended intervals between maintenance checks, contributing to overall productivity.

Importance of PILOT OPERATED CHECK VALVES

Role in Continuous Operation

PILOT OPERATED CHECK VALVES play a vital role in ensuring continuous operation within hydraulic systems. These valves allow fluid to flow in one direction while preventing backflow, which is crucial for maintaining pressure stability. When the system experiences fluctuations, these valves respond quickly to changes in pilot pressure. This responsiveness ensures that hydraulic machinery operates smoothly without interruptions.

Operators benefit from the integration of PILOT OPERATED CHECK VALVES in various applications. For instance, in construction equipment, these valves help maintain consistent hydraulic pressure during demanding tasks. This consistency enhances the overall efficiency of the machinery, allowing operators to complete projects on time.

Enhancing Safety and Stability

Safety is paramount in heavy machinery operations. PILOT OPERATED CHECK VALVES contribute significantly to this aspect by preventing backflow and maintaining pressure integrity. This feature reduces the risk of hydraulic system failures, which can lead to accidents or equipment damage. Operators can work with confidence, knowing that their systems are equipped with reliable safety mechanisms.

Moreover, the stability provided by these valves enhances the overall performance of hydraulic systems. By ensuring that pressure remains consistent, PILOT OPERATED CHECK VALVES help prevent sudden drops or spikes that could compromise machinery functionality. This stability is essential for operators who rely on precision and control in their work.

The HPLK valve plays a vital role in ensuring continuous operation in heavy machinery. Its design and functionality significantly enhance productivity and reliability. Operators benefit from reduced downtime and improved efficiency. By integrating the HPLK valve, they can achieve optimal performance in demanding environments.