Hydraulic counterbalance valves regulate fluid flow in hydraulic systems. They play a crucial role by preventing uncontrolled movements of loads. By doing so, you enhance safety and improve operational efficiency, allowing your machinery to perform smoothly and reliably.

Key Takeaways

- Counterbalance valves enhance safety by preventing uncontrolled load movements in hydraulic systems.

- These valves allow precise control over load lifting and lowering, improving operational efficiency.

- Regular maintenance, including inspections and functionality tests, ensures counterbalance valves operate smoothly and safely.

How Counterbalance Valves Work

Basic principles of operation

Counterbalance valves function as essential components in hydraulic systems. They maintain control over the movement of loads, especially when dealing with heavy machinery. When you apply pressure to lift a load, the counterbalance valve allows fluid to flow into the actuator. This action raises the load smoothly. However, if the load begins to descend unexpectedly, the valve automatically restricts fluid flow. This restriction prevents uncontrolled movement, ensuring safety and stability.

The operation of counterbalance valves relies on a few key principles:

- Pressure Regulation: The valve maintains a preset pressure level. This regulation ensures that the load does not fall too quickly.

- Flow Control: The valve controls the rate of fluid flow. You can adjust this rate based on the specific requirements of your application.

- Load Holding: When the actuator is not in use, the valve holds the load in place. This feature is crucial for safety during maintenance or when the machine is idle.

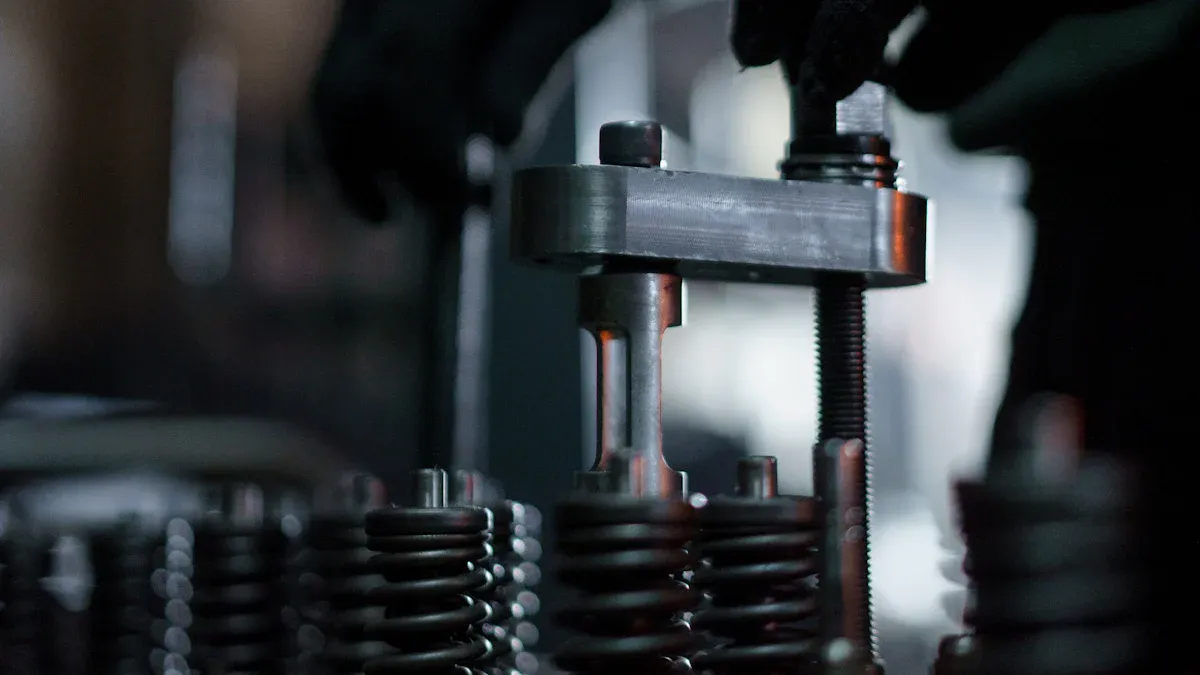

Key components and their functions

Understanding the key components of counterbalance valves helps you appreciate their role in hydraulic systems. Here are the main parts and their functions:

- Spring: The spring provides the necessary force to keep the valve closed until the system pressure exceeds a certain threshold. It plays a vital role in load holding.

- Piston or Spool: This component moves within the valve body. It opens or closes the flow path based on the pressure applied. When the load is lifted, the piston allows fluid to flow; when the load descends, it restricts flow.

- Adjustment Screw: This screw allows you to set the desired pressure level. By adjusting it, you can customize the valve’s response to different loads.

- Ports: These are the entry and exit points for hydraulic fluid. They connect the valve to the hydraulic circuit, facilitating fluid movement.

By understanding these components, you can better appreciate how counterbalance valves contribute to the efficiency and safety of hydraulic systems.

Applications of Counterbalance Valves

Industrial machinery

Counterbalance valves play a vital role in industrial machinery. You often encounter these valves in equipment like hydraulic presses, injection molding machines, and CNC machines. Their primary function is to control the movement of heavy loads. For instance, when you operate a hydraulic press, the counterbalance valve ensures that the ram descends smoothly and does not drop suddenly. This control enhances safety and prevents damage to both the machine and the workpiece.

In addition, counterbalance valves help maintain consistent pressure during operations. This consistency allows you to achieve precise results, which is crucial in manufacturing processes. By using these valves, you can improve the overall efficiency of your industrial machinery.

Construction equipment

In the construction industry, counterbalance valves are essential for equipment such as excavators, cranes, and forklifts. These machines often handle heavy loads and require precise control to ensure safety. When you lift a load with an excavator, the counterbalance valve regulates the fluid flow, allowing for smooth lifting and lowering. This regulation prevents the load from falling unexpectedly, protecting both operators and bystanders.

Moreover, counterbalance valves enhance the stability of construction equipment. They help maintain the position of the load when the machine is idle. This feature is particularly important when working on uneven terrain or during complex maneuvers. By incorporating counterbalance valves, you can significantly reduce the risk of accidents on the job site.

Material handling systems

Counterbalance valves also find extensive use in material handling systems. You may see them in conveyor systems, pallet jacks, and automated guided vehicles (AGVs). These systems often require precise control over the movement of goods. Counterbalance valves ensure that loads move smoothly and safely, preventing sudden drops or jerks.

For example, in a conveyor system, the counterbalance valve regulates the speed at which items move. This regulation helps maintain a steady flow of materials, improving productivity. Additionally, when using pallet jacks, these valves provide the necessary support to hold loads in place, allowing you to maneuver safely.

Benefits of Counterbalance Valves

Enhanced safety features

Counterbalance valves significantly enhance safety in hydraulic systems. They prevent uncontrolled load movements, which can lead to accidents. When you use these valves, they automatically restrict fluid flow if a load begins to descend unexpectedly. This feature protects both operators and bystanders from potential hazards. You can trust that your equipment will operate safely, even under heavy loads.

Improved load control

With counterbalance valves, you gain precise control over load movements. These valves allow you to adjust the speed at which loads lift and lower. This control is crucial when handling delicate materials or performing intricate tasks. For example, when operating a hydraulic press, you can ensure that the ram descends at a controlled rate. This capability minimizes the risk of damage to both the load and the machinery. You will find that improved load control leads to better overall performance in your operations.

Increased system efficiency

Incorporating counterbalance valves into your hydraulic systems boosts overall efficiency. These valves maintain consistent pressure, which helps reduce energy consumption. When you achieve smoother operations, you also minimize wear and tear on components. This efficiency translates into lower maintenance costs and longer equipment lifespan. By using counterbalance valves, you can optimize your hydraulic systems for maximum productivity.

Selecting the Right Counterbalance Valve

Factors to consider

When selecting a counterbalance valve, you must consider several key factors to ensure optimal performance. Here are some important aspects to keep in mind:

- Load Weight: Determine the maximum load weight your system will handle. This information helps you choose a valve that can manage the required pressure.

- Operating Pressure: Know the operating pressure of your hydraulic system. The valve must match this pressure to function effectively.

- Flow Rate: Assess the flow rate needed for your application. A valve that accommodates your flow requirements will enhance efficiency.

- Mounting Style: Consider the mounting style that fits your equipment. Different configurations exist, such as inline or subplate-mounted valves.

- Response Time: Evaluate how quickly you need the valve to respond to changes in load. A faster response time improves control and safety.

Common specifications and standards

Counterbalance valves come with various specifications and standards. Familiarizing yourself with these can help you make an informed choice. Here are some common specifications:

| Specification | Description |

|---|---|

| Pressure Rating | Indicates the maximum pressure the valve can handle. |

| Flow Capacity | Defines the maximum flow rate the valve can support. |

| Temperature Range | Specifies the operating temperature limits. |

| Material | Indicates the materials used in valve construction, affecting durability. |

By considering these factors and specifications, you can select the right counterbalance valve for your hydraulic system, ensuring smooth and safe operations.

Maintenance Tips for Counterbalance Valves

Regular inspection practices

To keep your counterbalance valves functioning optimally, establish a routine inspection schedule. Regular checks help you identify potential issues before they escalate. Here are some key practices to follow:

- Visual Inspection: Examine the valve for any signs of leaks or damage. Look for fluid stains around the valve body.

- Pressure Testing: Use a pressure gauge to ensure the valve maintains the correct pressure levels. This test helps confirm that the valve operates within specifications.

- Fluid Quality Check: Inspect the hydraulic fluid for contamination. Dirty fluid can affect valve performance and lead to premature wear.

- Functionality Test: Operate the machinery to observe the valve’s response. Ensure it opens and closes smoothly without sticking.

Troubleshooting common issues

Even with regular maintenance, you may encounter issues with your counterbalance valves. Here are some common problems and their solutions:

- Slow Response Time: If the valve responds slowly, check for blockages in the hydraulic lines. Clean or replace any obstructed components.

- Uncontrolled Load Movement: This issue may indicate a malfunctioning valve. Inspect the spring and piston for wear. Replace any damaged parts immediately.

- Fluid Leaks: Leaks can stem from worn seals or loose fittings. Tighten connections and replace seals as needed.

By following these maintenance tips, you can ensure your counterbalance valves operate smoothly and efficiently, enhancing the safety and performance of your hydraulic systems.

Hydraulic counterbalance valves are vital for safe and efficient operations in various applications. They enhance safety, improve load control, and increase system efficiency. You should explore additional resources to deepen your understanding of these essential components. Your knowledge will empower you to optimize hydraulic systems effectively.