The HSCBCA/HSCBCG-Counterbalance Cartridge valve provides innovative solutions for hydraulic system instability. These valves significantly enhance performance and reliability for clients across North America. They effectively tackle common issues such as hydraulic fluid contamination, temperature problems, and seal failures, ensuring smoother operations in various applications.

Key Takeaways

- HSCBCA and HSCBCG valves enhance hydraulic stability by managing pressure and flow effectively, preventing actuator creep.

- These valves utilize load-sensing technology for precise control, resulting in smoother operations and improved safety in hydraulic systems.

- Investing in HSCBCA and HSCBCG valves can lead to long-term savings by reducing maintenance costs and minimizing downtime.

Features of HSCBCA/HSCBCG-Counterbalance Cartridge Valves

Design Specifications

The HSCBCA/HSCBCG-Counterbalance Cartridge valves feature advanced design specifications that enhance their performance in hydraulic systems. These valves are engineered to handle high pressures and flow rates, making them suitable for various applications. Key specifications include:

- Maximum Setting Pressure:

- HSCBCA: 280 bar

- HSCBCG: 350 bar

- Maximum Load Pressure:

- HSCBCA: 215 bar

- HSCBCG: 270 bar

- Flow Rate: 120 L/Min

These specifications ensure that the valves can maintain hydraulic stability under varying load conditions. The design incorporates load-sensing technology, which enhances flow and pressure control. This technology allows for demand-based flow regulation, ensuring that the system operates efficiently.

Operational Mechanisms

The operational mechanisms of the HSCBCA/HSCBCG-Counterbalance Cartridge valves play a crucial role in maintaining hydraulic stability. These valves utilize counterbalance technology to manage load pressure effectively. Here are some key operational features:

- Positive Load Pressure Maintenance: The valves prevent actuator creep by maintaining positive load pressure. This feature is essential for safety during hydraulic failures.

- Integration of Compensators: The PVBM module integrates additional compensators to ensure consistent positive load pressure under varying operating conditions. This integration allows the system to adapt to changes in load without compromising performance.

Overall, the HSCBCA/HSCBCG-Counterbalance Cartridge valves provide a reliable solution for hydraulic instability challenges. Their innovative design and operational mechanisms ensure enhanced control and stability, making them a preferred choice for many applications.

Advantages Over Traditional Solutions

The HSCBCA/HSCBCG-Counterbalance Cartridge valves offer several advantages over traditional hydraulic solutions. These benefits significantly enhance system performance and reliability.

Improved Stability

One of the primary advantages of the HSCBCA/HSCBCG-Counterbalance Cartridge valves is their ability to improve stability in hydraulic systems. Traditional counterbalance valves often face issues that can lead to instability. Common failure modes include:

- Improper sizing or installation, which can cause excessive pressure drop or backpressure.

- Contamination from dirt or debris, leading to malfunction.

- Incorrect valve settings that prevent proper load counterbalancing.

- Worn or damaged seals and O-rings, resulting in leakage.

- Overloading the hydraulic system, which can damage the valve.

- Inadequate maintenance, contributing to valve failure.

The HSCBCA and HSCBCG valves effectively address these challenges. Their advanced design ensures that they maintain consistent load pressure, preventing actuator creep and enhancing overall system stability.

Enhanced Control

Enhanced control is another significant benefit of the HSCBCA/HSCBCG-Counterbalance Cartridge valves. These valves utilize load-sensing technology, allowing for precise flow and pressure regulation. This technology enables operators to achieve better control over hydraulic movements, resulting in smoother operations.

Moreover, the integration of compensators within these valves ensures that they adapt to varying load conditions without compromising performance. This adaptability allows for more responsive and efficient hydraulic systems, which is crucial in applications requiring high precision.

Cost-Effectiveness

Cost-effectiveness is a vital consideration for any hydraulic system. The HSCBCA/HSCBCG-Counterbalance Cartridge valves provide long-term savings by reducing maintenance costs and minimizing downtime. Their robust design and high-quality materials lead to increased durability and reliability.

By addressing common failure modes found in traditional valves, these cartridge valves reduce the frequency of repairs and replacements. This reliability translates into lower operational costs for businesses, making them a smart investment for hydraulic systems.

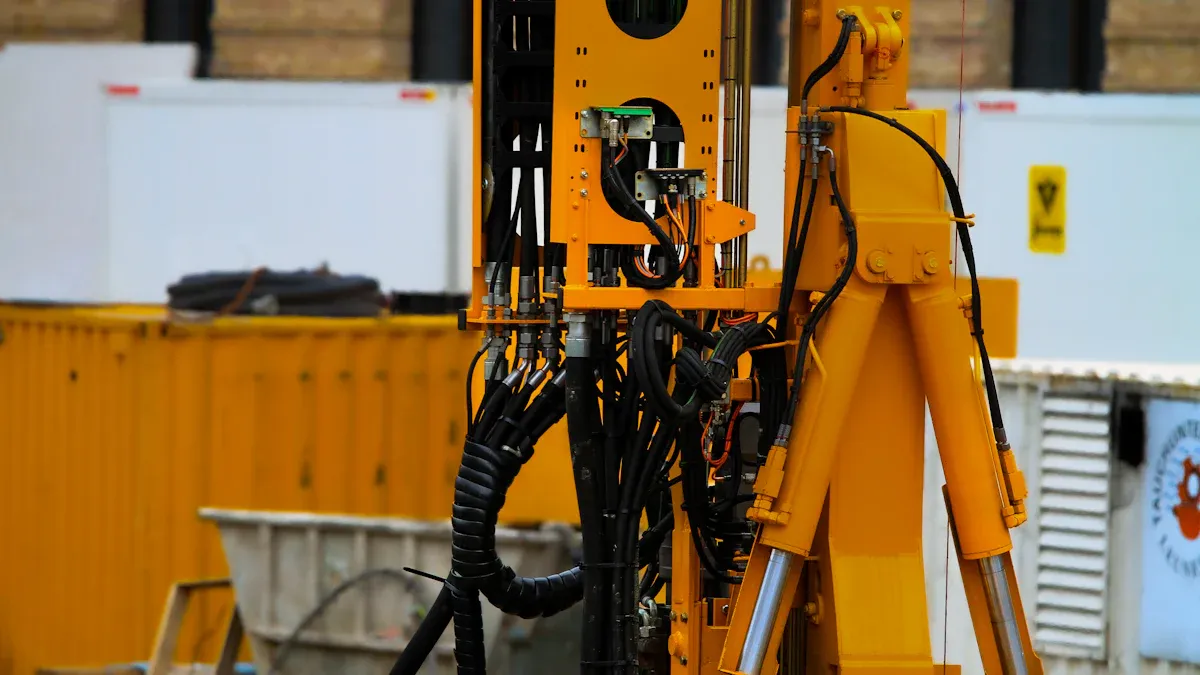

Real-World Applications of HSCBCA/HSCBCG-Counterbalance Cartridge Valves

Case Study: Industrial Machinery

In the industrial sector, companies often face challenges with hydraulic stability. One manufacturer of heavy machinery implemented the HSCBCA/HSCBCG-Counterbalance Cartridge valves in their hydraulic systems. They reported a significant reduction in actuator creep and improved load control. This enhancement allowed for safer operations and increased productivity. The valves maintained consistent pressure, even under varying loads, which minimized downtime and maintenance costs.

Case Study: Mobile Equipment

Mobile equipment operators also benefit from these innovative valves. A construction company integrated the HSCBCA/HSCBCG-Counterbalance Cartridge valves into their excavators. The results were impressive. Operators experienced smoother movements and better control over the equipment. The valves effectively managed load pressure, preventing sudden drops that could lead to accidents. This reliability improved overall safety on job sites, allowing workers to focus on their tasks without worrying about hydraulic failures.

Client Testimonials

Clients consistently praise the performance of the HSCBCA/HSCBCG-Counterbalance Cartridge valves. One client stated, “These valves transformed our hydraulic systems. We noticed immediate improvements in stability and control.” Another client remarked, “The durability of these valves has saved us time and money. We rarely face issues now.” Such testimonials highlight the effectiveness of these valves in addressing hydraulic instability challenges.

The HSCBCA and HSCBCG valves effectively address hydraulic instability by managing pressure and flow. Their advanced design enhances safety and productivity in hydraulic systems.

Key Benefits for North American Clients:

- Energy Savings: LoadAdaptive CECA valves offer up to 30% energy savings.

- Lower Pilot Pressure: They require only 900 psi (60 bar) to set effective pressure.

These features make HSCBCA and HSCBCG valves a smart choice for improving hydraulic system performance. Explore these innovative solutions today!

| Valve Type | Energy Savings | Pilot Pressure Required to Set Effective Pressure to 0 psi |

|---|---|---|

| Standard CBCA | N/A | 1500 psi (105 bar) |

| LoadAdaptive CECA | 30% | 900 psi (60 bar) |

FAQ

What are HSCBCA and HSCBCG valves used for?

HSCBCA and HSCBCG valves manage hydraulic pressure and flow, enhancing stability in various hydraulic systems.

How do these valves improve system performance?

These valves utilize advanced design and load-sensing technology to maintain consistent pressure, reducing actuator creep and enhancing control.

Are HSCBCA and HSCBCG valves cost-effective?

Yes, these valves reduce maintenance costs and downtime, providing long-term savings for businesses using hydraulic systems.