A hydraulic control valve for dump truck precisely regulates hydraulic fluid. This enables smooth operation of the dump bed. It prevents sudden movements. The valve ensures secure lifting and lowering of loads. This enhances both stability and safety in heavy-duty hauling.

Key Takeaways

- Hydraulic control valves help dump trucks lift and lower heavy loads safely. They make sure the dump bed moves smoothly.

- These valves protect the truck from too much pressure and have safety features for emergencies. This helps prevent accidents.

- Regular checks and maintenance of these valves keep the dump truck working well and safely for a long time.

Precision Control: The Core of Hydraulic Control Valve for Dump Truck Stability

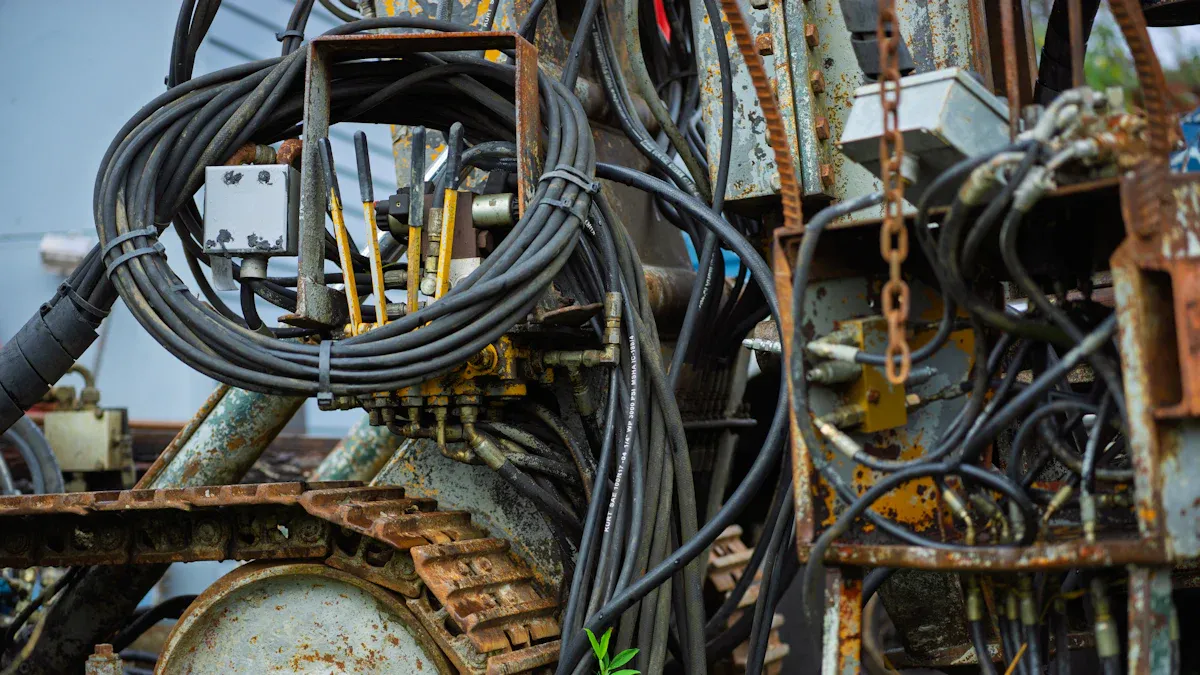

Dump trucks rely on hydraulic systems for their powerful lifting capabilities. These systems provide the force needed to raise heavy loads. Precision control is essential for safe and stable operation. A hydraulic control valve for dump truck plays a central role in achieving this precision.

How Hydraulic Systems Power Dump Truck Lifts

Hydraulic systems convert mechanical energy into hydraulic energy, then back into mechanical energy. This process lifts the dump bed. Key components work together to achieve this.

- Hydraulic Pump: This component is the heart of the hydraulic system. It draws hydraulic fluid from a reservoir. It then pressurizes the fluid. This pressurized fluid powers the cylinders. Smaller trucks often use gear pumps. Larger, heavy-duty trucks use piston pumps. The pump converts the engine’s mechanical energy into hydraulic energy. It typically operates at a maximum pressure of about 2.0 MPa and a maximum speed of 2500 rpm. The gearbox’s power take-off drives it.

- Control Elements: These components manage the hydraulic oil. They adjust its pressure, flow, and direction. Dump truck systems often use a pneumatic hydraulic control mode. This includes a three-position six-way manual pneumatic control valve. It also features a three-position three-way lifting distribution valve and a two-position three-way solenoid valve. Main components include an air control valve, a lifting distribution valve, and a limit valve.

- Hydraulic Cylinders: These critical components transform pressurized hydraulic fluid into linear motion. This motion lifts and lowers the dump bed. Dump trucks usually have two cylinders. They work together for stability during dumping. Their size and design depend on the truck’s capacity. High-pressure oil enters through a single oil port to jack up the cylinder. When lowering, gravity returns the cylinder to its position. This sends hydraulic oil back to the tank.

The pressure and flow rates within these systems are significant. For example, lifting 15,000 lbs with a 3-inch cylinder requires approximately 2,122 PSI. This can be closer to 2,250 PSI when considering pump pressure, seal friction, and back pressure. A 2.5-inch cylinder needs 3,055 PSI for the same load. A 3.5-inch cylinder requires 1,560 PSI. Initial pressure to raise a dump truck body should not exceed 600–800 PSI. Flow rates for cylinder extension can be around 20 GPM. Retraction flow rates can be much higher, sometimes 120 GPM or even 140 GPM in specific scenarios.

Types of Hydraulic Control Valves and Their Functions

Different types of hydraulic control valves perform specific tasks within the dump truck’s hydraulic system. They ensure precise and safe operation.

| Type of Valve | Description | Applications |

|---|---|---|

| Directional Control Valve | This valve controls the direction of hydraulic fluid flow. | It is common in dump truck lift systems. |

| Flow Control Valve | This valve regulates the flow rate of hydraulic fluid. | It adjusts the dump speed. |

| Pressure Relief Valve | This valve prevents system overload. It relieves excess pressure. | It acts as a safety feature in hydraulic systems. |

| Check Valve | This valve allows fluid to flow in one direction only. | It protects hydraulic systems from backflow. |

| Proportional Valve | This valve provides variable control of flow and pressure. | It offers precision control in complex systems. |

These valves work together. They manage the movement of the dump bed. They also prevent system damage.

Smooth Lifting and Lowering with Flow Control

Flow control valves are crucial for smooth and controlled dump bed movements. They regulate the rate of fluid flow. This regulation ensures the hydraulic cylinders operate smoothly.

- The hydraulic pump’s flow rate determines how fast hydraulic fluid powers the cylinders.

- Incorrect flow rates can cause slow or uneven cylinder operation.

- Before making adjustments, operators must know the optimal flow rate for their dump truck model. This information is usually in the manufacturer’s manual.

- Operators locate the flow control valve. It is typically on the hydraulic pump or directional control valve. The manufacturer’s manual helps find it.

- Operators adjust the flow control valve to achieve the recommended rate. They use a flow meter to measure the current rate.

- They verify system performance. They operate the hydraulic cylinders in a controlled setting.

This careful adjustment of flow control valves ensures the dump bed lifts and lowers smoothly. It prevents sudden, jerky movements. This enhances both stability and safety during heavy-duty hauling operations.

Enhancing Safety: Mitigating Risks with Hydraulic Control Valve for Dump Truck

Dump truck operations carry inherent risks. Heavy loads and elevated dump beds can lead to instability. Hydraulic control valves play a vital role in reducing these dangers. They ensure safer working conditions.

Overload Protection and Pressure Management

Dump trucks face significant risks from instability during lifting. Several factors can cause tip-overs. The load’s center of gravity might move outside the truck’s frame rails when the bed is up. Uneven load distribution also creates problems. This happens from uneven packing, or when the truck operates on slopes or soft ground. Sometimes, the load does not flow correctly during dumping. This can cause materials to remain on one side. The truck’s stability also suffers if the back wheels settle unevenly as the load shifts. Mechanical issues like poor rear suspension, uneven tire pressure, or worn lifting components also contribute to instability.

To counter these risks, hydraulic systems include robust safety features. Hydraulic pumps often have built-in safety valves. These valves prevent overloading. This helps ensure reliability and extends equipment life. Power units also feature strong overload protection and durable tanks. These features enhance safety in demanding applications.

Pressure limiting valves are key components. They stop the hydraulic system from exceeding safe pressure limits. This protects the entire system. Knock-off valves control tipping angles. They prevent the dump truck’s bed from extending too far. This avoids unsafe over-extension.

Pressure relief valves are crucial safety devices. They prevent damage by ensuring system pressure stays below a set maximum. This protects pipes, hoses, and fittings from bursting. For individual parts like pumps, motors, and hydraulic cylinders, relief valves stop them from facing pressures beyond their design limits. This prevents early wear or sudden failure. A main relief valve typically sets the highest system pressure. Smaller relief valves protect specific parts from sudden pressure spikes. These valves work by opening when system pressure overcomes a spring’s force. They then divert excess fluid, usually back to the reservoir. This reduces pressure to safe levels.

Emergency Lowering and Fail-Safe Mechanisms

Operators must remain at the controls throughout the dumping process. This allows them to react quickly to any issues. If the dump body starts to lean, the operator should immediately lower it. They should slowly move the cylinder control valve into the ‘hold’ position. This prevents high pressure. When loads get stuck, the operator should lower the dump body with the cylinder control valve partially open. They should not open it fully. Before leaving the machine, operators must relieve hydraulic pressure. They do this by moving the control valve back and forth multiple times.

A hydraulic control valve for dump truck is crucial for safe operation. It allows precise control over the dump body’s movement. This helps prevent rollovers, lateral tilts, and other accidents. Correct use of these valves, such as slow positioning or partial opening, helps reduce risks from high pressure and unstable loads.

Fail-safe mechanisms are also essential. Pneumatic dump valves, common in heavy vehicles, must include fail-safe features. They also need emergency shut-off capabilities. These components are critical. They prevent accidental dumping if the system malfunctions. This ensures compliance with regulations from bodies like OSHA and ECE R131.

Operator Control and Ergonomics for Safer Operations

Modern dump truck designs prioritize operator comfort and safety. Ergonomic design features a main operating lever with clear yellow markings. Two auxiliary buttons complement this lever for intuitive control. A prominent red emergency stop button is also included. It is easy to access for quick reactions.

Control valve designs also focus on ergonomics. Handles are scientifically contoured. They have optimized grip geometry and non-slip surfaces for secure control. The actuation force is precisely calibrated. This minimizes wrist strain and repetitive stress. Optimized angular travel also helps reduce wrist strain. Fatigue-free control valve designs improve working conditions. They also enhance operational precision.

Advanced control interfaces improve operator precision and safety. These interfaces feature user-friendly designs. They also include advanced safety mechanisms. A user-friendly interface makes control easier and more precise. Advanced safety mechanisms contribute to overall operational safety.

Some systems remove operators from hazardous environments. Automated vehicles, similar to dump trucks, allow remote operation from a safe control room. This significantly reduces human exposure to risks. It minimizes accidents and workplace injuries. Remote monitoring and control systems also help. Central control rooms use telemetry and sensor networks. They monitor multiple trucks in real-time. This reduces the need for human presence on-site. It also provides early warnings for potential failures. This improves safety.

Collision avoidance and safety sensors are integrated into these systems. LiDAR, radar, and proximity sensors enhance situational awareness. They detect obstacles, control braking, and maintain safe distances. This minimizes accidents and protects personnel. Automation also ensures consistent load handling and placement. It places material accurately within pre-defined load parameters. This reduces rework and spillage. It directly improves precision compared to human drivers. Advanced control interfaces also use load cells in suspension systems. These cells monitor load weight. They optimize weight distribution. This directly improves precision and safety during operation.

Maintaining Optimal Performance of Hydraulic Control Valve for Dump Truck

Proper maintenance ensures the longevity and reliability of a dump truck’s hydraulic system. Regular care prevents costly breakdowns and maintains safety standards.

Regular Inspection and Servicing for Longevity

Regular inspections are crucial for hydraulic system health. Technicians recommend control valve adjustment as part of the 250-hour service for dump trucks. This proactive approach helps identify potential issues early. Malfunctioning valves, such as those that stick or leak, severely impair the equipment’s performance. They can lead to inefficient operation or even system failure. Consistent servicing ensures all components function correctly. This extends the lifespan of the entire hydraulic system. It also maintains the precision and safety of lifting operations.

Selecting the Right Valves for Specific Applications

Choosing the correct hydraulic control valve for dump truck applications is vital. Control valves manage fluid flow. They enable the operation of multiple applications within a single hydraulic system. These valves are necessary when an application frequently needs adjustments in pressure or flow rate. This maintains optimal performance. For systems handling multiple applications, proper sizing is crucial. Control valves may be needed to protect the system from excessive wear. Selecting valves that match the truck’s specific operational demands ensures efficiency and durability. This also enhances overall system reliability.

Hydraulic control valves are fundamental for superior lifting stability and safety in heavy-duty hauling. A hydraulic control valve for dump truck prevents accidents. It ensures precise load handling. It also extends equipment lifespan. These valves are critical components for efficient and secure dump truck operations.

FAQ

What is the main function of a hydraulic control valve for a dump truck?

A hydraulic control valve for a dump truck precisely regulates hydraulic fluid. It controls the dump bed’s lifting, lowering, and holding actions. This ensures stable and secure load handling.

How do hydraulic control valves enhance safety in dump truck operations?

These valves prevent accidents. They offer overload protection and smooth operation. They also include fail-safe mechanisms and emergency lowering features. This significantly reduces risks during heavy-duty hauling.

How often should operators inspect hydraulic control valves on dump trucks?

Operators should inspect hydraulic control valves regularly. Technicians recommend adjustments during the 250-hour service. This proactive maintenance ensures longevity and reliable performance.