Hanshang‘s HPS-08 sequence valves redefine compact design and functionality in 2026. They offer unparalleled precision and adaptability for modern industrial applications. The HPS-08 is a groundbreaking solution in sequence valve technology. Its core differentiators include a compact design, a non-rotating adjustment rod, and an industrial universal port.

Key Takeaways

- Hanshang’s HPS-08 valves are small. They save space on machines. This helps make systems simpler.

- The HPS-08 valves have a special rod. It does not turn when you set the pressure. This makes the pressure very steady.

- These valves connect easily to many systems. They have a universal port. This makes them useful for many jobs.

The Core of Compact: Unpacking the HPS-08 Sequence Valves’ Revolutionary Design

Beyond Size: What ‘Compact’ Truly Means for the HPS-08 Sequence Valves

Compact design in the HPS-08 sequence valves extends beyond mere physical dimensions. It represents a strategic engineering approach. Hanshang designed these valves to maximize functionality within a minimal footprint. This means industries can integrate them into tighter spaces. They also reduce the overall size of hydraulic manifolds. This efficiency saves valuable space on machinery. It also simplifies system layouts. The HPS-08 sequence valves deliver powerful performance without demanding extensive room. This redefines what “compact” truly signifies in industrial hydraulics.

Engineering for Efficiency: The Non-Rotating Adjustment Rod Advantage in HPS-08 Sequence Valves

The non-rotating adjustment rod is a key innovation in the HPS-08 sequence valves. Traditional adjustment mechanisms often involve a rod that rotates as users set the pressure. This can lead to wear and potential instability over time. Hanshang’s design eliminates this rotation. The rod remains stationary while adjustments occur. This feature ensures consistent and precise pressure settings. It also prevents the rod from backing out due to vibration. Operators achieve accurate control with greater reliability. This design enhances the valve’s longevity and operational stability.

Universal Adaptability: The Industrial Universal Port of HPS-08 Sequence Valves Explained

The industrial universal port of the HPS-08 sequence valves offers significant advantages. This standardized port design allows for broad compatibility. Manufacturers can easily integrate these valves into diverse hydraulic systems. This reduces the need for specialized fittings or adapters. It simplifies inventory management for businesses. The universal port also speeds up installation processes. It provides flexibility for system designers. This adaptability makes the HPS-08 sequence valves a versatile choice for many industrial applications. It streamlines operations and enhances system integration.

Performance Unleashed: Key Features and Operational Benefits of HPS-08 Sequence Valves

Precision Control: Achieving Optimal System Sequencing with HPS-08 Sequence Valves

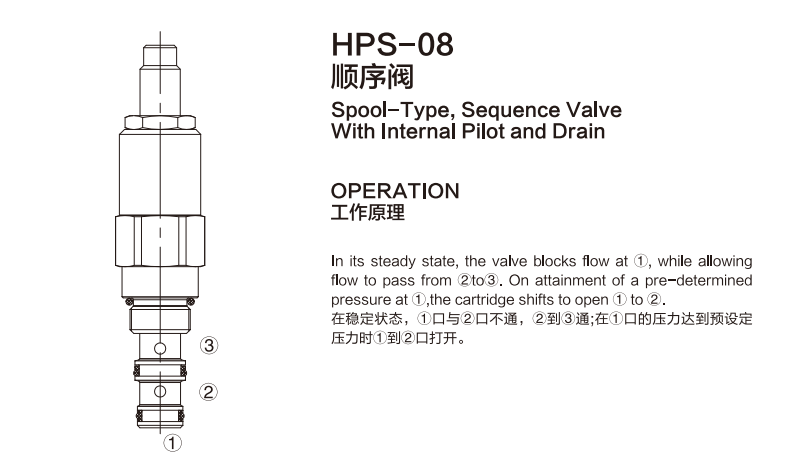

Hanshang’s HPS-08 sequence valves deliver exceptional precision in hydraulic system sequencing. Their spool-type design, featuring an internal pilot and drain, ensures accurate pressure activation. The valve blocks flow from port ①, allowing fluid only from port ② to port ③, until the pressure at port ① reaches a predetermined set point. At this precise moment, the valve spool shifts, opening the path from port ① to port ②. This mechanism guarantees that subsequent operations in a hydraulic circuit activate only after the preceding step completes its function and builds sufficient pressure. The non-rotating adjustment rod further enhances this precision. It allows operators to set the activation pressure with fine accuracy and maintains that setting reliably, even under dynamic operating conditions. This level of control prevents premature actions and ensures the smooth, synchronized operation of complex machinery.

Durability and Longevity: HPS-08 Sequence Valves Built for the Toughest Environments

Hanshang engineers the HPS-08 sequence valves for enduring performance in demanding industrial settings. They construct the valve body from robust materials, capable of withstanding maximum operating pressures up to 207 Bar. For applications requiring even greater resilience, a 6061-T6 aluminum option extends this capacity to 350 Bar. The internal components are designed to resist wear and fatigue, contributing to a long service life. The non-rotating adjustment rod, a key feature, eliminates rotational friction during adjustments, further reducing wear and tear on critical parts. These design choices ensure the valves maintain their operational integrity and performance characteristics over extended periods, minimizing the need for frequent replacements and providing a reliable solution for continuous industrial operations.

Simplified Maintenance and Reduced Downtime with HPS-08 Sequence Valves

The HPS-08 sequence valves significantly contribute to simplified maintenance routines and reduced operational downtime. Their compact design allows for easier installation and removal, especially in confined spaces. The industrial universal port further streamlines integration, eliminating the need for custom fittings and simplifying spare parts inventory. Operators can quickly and accurately adjust the valve’s pressure setting thanks to the non-rotating adjustment rod, which maintains its position without drift. This stability means fewer adjustments over time. The robust construction and inherent durability of the valves also translate into less frequent failures and, consequently, less unscheduled downtime. When maintenance is required, the straightforward design facilitates quicker troubleshooting and component replacement, ensuring machinery returns to full operation swiftly.

Real-World Impact: Applications and Future Prospects for HPS-08 Sequence Valves

Where the HPS-08 Sequence Valves Shine: Typical Industrial Applications

Hanshang’s innovative valves find extensive use across various industrial sectors. Manufacturers integrate these components into automation systems, ensuring precise operational sequences. In heavy machinery, they manage complex hydraulic circuits, guaranteeing safety and efficiency. Machine tools benefit from their compact size, allowing for streamlined designs and improved performance. The valves are crucial in material handling equipment, controlling the precise movement of loads. Their robust construction makes them ideal for harsh environments found in construction and mining. These applications leverage the valves’ ability to provide reliable, sequential control, optimizing overall system functionality and reducing operational errors. Their adaptability ensures seamless integration into existing and new hydraulic setups.

The Hanshang Commitment: Innovation and Support for HPS-08 Sequence Valves

Hanshang Hydraulic, established in 1988, demonstrates a strong commitment to innovation and customer support. The company invests heavily in research and development, continuously improving its hydraulic valve and system offerings. Hanshang operates a 12,000-square-meter facility, equipped with over 100 advanced manufacturing machines. These include CNC digital lathes, machining centers, and high-precision grinding and honing machines. Hanshang implements an ERP administration model and holds ISO9001:2008 and CE certifications. This ensures high-quality production and reliable products. Hanshang aims to create the best brand in the hydraulic field. The company welcomes business cooperation, providing expert support and innovative solutions for industrial needs.

Technical Deep Dive: HPS-08 Sequence Valves Specifications and Integration

Key Technical Specifications of HPS-08 Sequence Valves at a Glance

Hanshang’s HPS-08 sequence valves offer robust performance. They operate at a maximum working pressure of 207 Bar. A special 6061-T6 material option extends this to 350 Bar for demanding applications. The valves accommodate various flow rates; users can consult the pressure drop-flow performance chart for specific details. Standard spring ranges provide activation pressures from 3.5 to 20.7 Bar. High-range springs offer settings between 6.9 and 41.4 Bar. These valves function reliably in temperatures from -30℃ to 120℃. They are compatible with mineral oil, ensuring broad industrial applicability. The standard port size is 08-3.

Seamless Integration of HPS-08 Sequence Valves into Existing Systems

Integrating the HPS-08 sequence valves into current hydraulic setups is straightforward. Their industrial universal port design eliminates the need for specialized adapters. This feature simplifies system connections. The compact form factor allows installation in tight spaces. Engineers can easily incorporate these valves into existing manifolds or new designs. This adaptability reduces installation time and complexity. It also minimizes inventory requirements for various fittings. Businesses achieve greater flexibility in system design and modification.

Comparative Advantages of HPS-08 Sequence Valves Over Traditional Valves

The HPS-08 sequence valves offer distinct advantages over older designs. Their non-rotating adjustment rod provides superior precision and stability. This design prevents accidental pressure changes. Traditional valves often suffer from rod rotation, leading to drift. The compact size of the HPS-08 saves valuable space on machinery. Older valves typically require more room. The universal port enhances compatibility, unlike proprietary connections found in many conventional valves. This design choice simplifies maintenance and reduces the need for specialized parts.

Hanshang’s HPS-08 sequence valves redefine expectations, setting a new standard for 2026 and beyond. They offer a compact design, precision from the non-rotating rod, and the versatility of a universal port. These features establish a new benchmark for sequence valve technology. Explore Hanshang’s solutions for your industrial needs.

FAQ

How does the HPS-08 valve’s compact design benefit industrial applications?

The compact design saves valuable space on machinery. It simplifies system layouts. This efficiency allows integration into tighter areas.

What is the advantage of the non-rotating adjustment rod in HPS-08 valves?

The non-rotating rod ensures consistent pressure settings. It prevents wear and instability. This design enhances reliability and longevity.

Can the HPS-08 sequence valves integrate into existing hydraulic systems?

Yes, the industrial universal port allows easy integration. It reduces the need for specialized fittings. This feature simplifies system adaptation.