Selecting the correct double counterbalance valve is paramount for hydraulic system safety, efficiency, and longevity. This guide provides essential knowledge. It helps you choose ideal COUNTERBALANCE VALVES. This ensures optimal hydraulic performance and prevents common issues. Many hydraulic systems rely on quality hydraulic valves. Hanshang valves offer reliable options.

Key Takeaways

- A double counterbalance valve controls hydraulic actuators. It holds loads safely and prevents uncontrolled movement.

- Choose the right valve by checking pressure, flow, and pilot ratio. This ensures your hydraulic system works well.

- Install and maintain the valve correctly. This makes it last longer and work reliably.

Understanding the Double Counterbalance Valve: Function and Importance

What is a Double Counterbalance Valve?

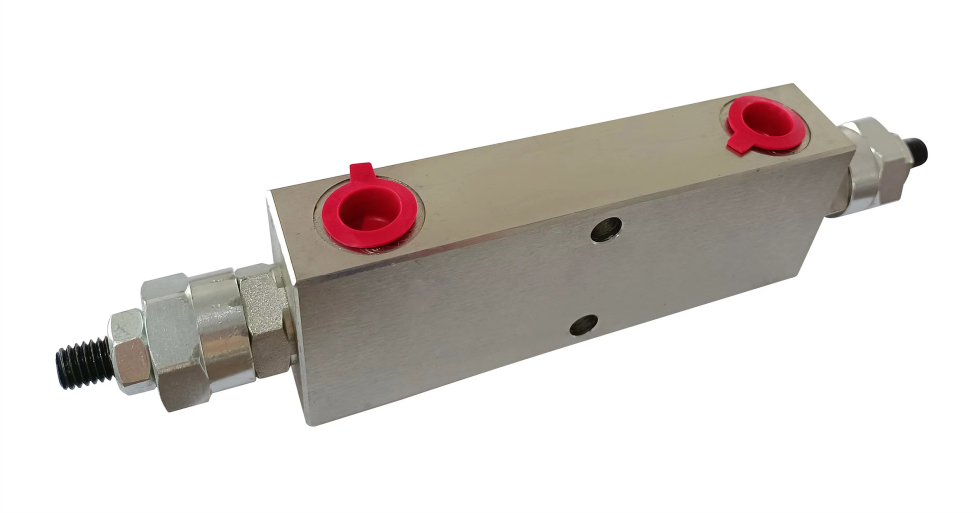

A double counterbalance valve is a crucial component in hydraulic systems. It manages the movement of hydraulic actuators, such as cylinders or motors. This valve controls fluid flow in both directions. It ensures stable and controlled operation, especially with suspended loads.

How a Double Counterbalance Valve Works

This valve module has two sections. Each section contains a check valve and a relief valve. Pressure in the opposite line pilots the relief valve. The check section allows free flow into the actuator. It then holds the load against reverse movement. When pilot pressure applies to the line across, the relief valve’s pressure setting reduces. This reduction is proportional to a stated ratio. The valve then opens, allowing controlled reverse flow. Back-pressure at the valve’s ports adds to the pressure setting.

Why a Double Counterbalance Valve Prevents Runaway Loads and Cavitation

The valve prevents runaway loads. It maintains a constant back pressure on the actuator. This stops the load from accelerating uncontrollably. It also prevents cavitation. Cavitation occurs when pressure drops too low, forming vapor bubbles. The valve ensures fluid fills the actuator, avoiding these issues. This protects the system from damage.

Enhancing Safety and Precision with a Double Counterbalance Valve

This valve significantly enhances safety. It provides precise control over load movement. Operators can stop or hold loads securely in any position. This precision is vital for applications requiring fine adjustments. It also protects personnel and equipment from unexpected load drops. The double counterbalance valve ensures reliable and safe hydraulic operations.

Key Criteria for Selecting the Right Double Counterbalance Valve

Choosing the correct double counterbalance valve is essential for optimal hydraulic system performance. Several key factors guide this selection process. Understanding these criteria helps engineers and technicians make informed decisions.

Pressure Rating for Your Double Counterbalance Valve

The pressure rating of a double counterbalance valve must match or exceed the maximum operating pressure of the hydraulic system. System pressure can fluctuate significantly. Selecting a valve with an insufficient pressure rating leads to premature failure. It also creates safety hazards. Always consider potential pressure spikes and ensure the valve can safely handle them. Manufacturers provide clear specifications for maximum working pressure. Adhering to these limits guarantees reliable operation and extends valve life.

Flow Rate Capacity of the Double Counterbalance Valve

The flow rate capacity of the double counterbalance valve is another critical consideration. This capacity must accommodate the maximum flow rate required by the actuator it controls. If the valve’s flow capacity is too low, it restricts fluid movement. This causes excessive pressure drops and heat generation. Conversely, an oversized valve might not offer precise control. It could also be more expensive and physically larger than necessary. Match the valve’s flow rating to the actuator’s maximum flow requirements for efficient and smooth operation.

Pilot Ratio: Impact on Double Counterbalance Valve Control

The pilot ratio significantly influences how a double counterbalance valve responds to changes in pressure. This ratio describes the relationship between the pilot pressure and the load pressure required to open the valve. A higher pilot ratio means less pilot pressure is needed to open the valve. This results in a more responsive system. However, a very high ratio can make the system less stable. A lower pilot ratio requires more pilot pressure. This offers greater stability but can make the system less responsive. Selecting the appropriate pilot ratio balances responsiveness with stability for the specific application.

Cracking Pressure of the Double Counterbalance Valve

Cracking pressure refers to the minimum pressure required to initiate flow through the valve. For a double counterbalance valve, this setting is crucial for controlling load movement. A correctly set cracking pressure ensures the load remains held until the system actively commands movement. If the cracking pressure is too low, the load might drift. If it is too high, the system may struggle to initiate movement smoothly. Proper adjustment of the cracking pressure is vital for precise load control and preventing unintended motion.

Port Size and Mounting Options for Your Double Counterbalance Valve

Port size and mounting options affect system integration and performance. The valve’s port size must match the hydraulic lines connected to it. Incorrect port sizing leads to flow restrictions or leaks. Common mounting options include cartridge, inline, and subplate designs. Cartridge valves fit into custom manifolds, offering compact solutions. Inline valves connect directly into hydraulic lines. Subplate mounted valves attach to a subplate, allowing for easier maintenance and system modification. Choose the option that best fits the system layout and maintenance needs.

Material and Seal Compatibility for the Double Counterbalance Valve

The materials used in the valve’s construction and its seals must be compatible with the hydraulic fluid and the operating environment. Different hydraulic fluids have varying chemical compositions. Incompatible materials can lead to corrosion, seal degradation, and valve failure. Extreme temperatures, corrosive atmospheres, or abrasive particles also demand specific material choices. Common seal materials include Nitrile (Buna-N), Viton, and EPDM, each suited for different conditions. Always verify material and seal compatibility to ensure long-term reliability and prevent costly downtime.

Application-Specific Considerations for Your Double Counterbalance Valve

Selecting the right hydraulic components requires careful thought about the specific application. A double counterbalance valve performs differently based on its operating environment and the demands placed upon it. Understanding these application-specific factors ensures optimal performance and system longevity.

Mobile vs. Industrial Double Counterbalance Valve Applications

Mobile and industrial hydraulic systems present distinct challenges for valve selection. Mobile applications, such as construction equipment or agricultural machinery, often experience harsh conditions. These include vibrations, temperature extremes, and exposure to dirt and moisture. Valves for mobile use require robust construction, compact designs, and excellent resistance to environmental factors. Industrial applications, found in factories or processing plants, typically operate in more controlled environments. Here, precision, continuous operation, and ease of maintenance often take precedence. Industrial valves might be larger and focus on long-term durability and precise control. The choice of a double counterbalance valve must align with these differing operational demands.

Double Counterbalance Valve Selection for Vertical vs. Horizontal Loads

The orientation of the load significantly impacts valve selection. Vertical loads, like those lifted by a crane or a forklift, are subject to gravity. They require a valve that can reliably hold the load in position and prevent uncontrolled descent. The valve must manage potential runaway conditions effectively. Horizontal loads, such as those pushed or pulled, primarily deal with friction and inertia. While still needing control, the risk of a sudden, uncontrolled drop is lower. However, precise stopping and starting are still critical. The valve’s pilot ratio and cracking pressure settings become especially important for vertical loads to ensure safety and smooth operation.

Dynamic vs. Static Load Requirements for a Double Counterbalance Valve

Hydraulic systems handle both dynamic and static loads. Dynamic loads involve movement, acceleration, and deceleration. For these, the double counterbalance valve must provide smooth transitions and prevent shock. It needs to react quickly to changes in load conditions. Static loads, on the other hand, involve holding a load in a fixed position for extended periods. Here, the valve must maintain pressure and prevent drift with minimal leakage. A valve designed for dynamic loads might prioritize responsiveness, while one for static loads emphasizes holding capability and minimal internal leakage. Engineers must consider the primary type of load the system will encounter.

Environmental Factors Affecting Double Counterbalance Valve Performance

The operating environment plays a crucial role in valve performance and lifespan. Temperature extremes, both high and low, can affect hydraulic fluid viscosity and seal integrity. High temperatures can degrade seals and fluid, while low temperatures can make fluid sluggish. Corrosive atmospheres, such as those found in marine or chemical processing environments, demand valves made from resistant materials. Dust, dirt, and other contaminants can cause wear and blockages. Systems operating in such conditions require valves with superior sealing and filtration. Selecting a valve with appropriate materials, seals, and protective features ensures reliable operation despite challenging environmental conditions.

Installation and Maintenance of Your Double Counterbalance Valve

Proper Installation Techniques for a Double Counterbalance Valve

Correct installation ensures optimal performance and safety. Install the valve according to the manufacturer’s instructions. Observe the flow direction arrows on the valve body. Incorrect orientation can lead to system malfunction. Torque all fittings to the specified values. This prevents leaks and maintains system integrity. Keep the hydraulic system clean during installation. Contaminants can damage internal components.

Setting and Adjustment of Your Double Counterbalance Valve

Proper setting of the double counterbalance valve is crucial. Adjust the valve’s pressure setting to match the load requirements. Use a pressure gauge to verify the settings. Follow the manufacturer’s recommended procedures for adjustment. Incorrect settings can cause load drift or erratic movement. Test the system thoroughly after any adjustments. This confirms stable and controlled operation.

Troubleshooting Common Double Counterbalance Valve Issues

Operators may encounter common issues. If a load drifts, check the valve’s pressure setting. Contamination can also cause sticking or leakage. Erratic movement often indicates air in the system or incorrect pilot pressure. Always consult the valve’s manual for specific troubleshooting steps. A systematic approach helps identify and resolve problems efficiently.

Regular Maintenance for Double Counterbalance Valve Longevity

Regular maintenance extends the life of your hydraulic components. Maintain clean hydraulic fluid. Contaminated fluid is a leading cause of valve wear. Inspect seals periodically for signs of wear or damage. Replace worn seals promptly. Check mounting bolts for proper torque. A well-maintained double counterbalance valve provides reliable performance for many years.

Selecting the correct double counterbalance valve is vital for hydraulic system safety, efficiency, and longevity.

One ensures optimal performance by considering pressure, flow, pilot ratio, and application-specific needs. Always consult manufacturer specifications. Seek expert advice for unique hydraulic challenges.

FAQ

What is the main purpose of a double counterbalance valve?

A double counterbalance valve controls hydraulic actuator movement. It holds loads securely. The valve also prevents uncontrolled motion in both directions.

How does a double counterbalance valve prevent runaway loads?

The valve maintains back pressure on the actuator. This stops the load from accelerating too quickly. It ensures controlled descent or movement.

Can a double counterbalance valve cause cavitation?

No, it prevents cavitation. The valve ensures fluid consistently fills the actuator. This avoids low-pressure conditions that cause vapor bubbles.