4WMM6 series manually operated directional valves play a crucial role in fluid control systems. These valves allow operators to direct fluid flow manually, ensuring precise control. Their significance lies in their ability to handle various pressures and fluids, making them versatile for many applications.

| Specification | 4WMM6D5X/F |

|---|---|

| Type | Manually operated directional valve |

| Maximum Pressure | As specified in product group ID |

| Ports | Multiple for comprehensive fluid control |

| Actuation | Manual with hand lever |

| Return Springs | One or two for central position maintenance |

| Detents | Yes, for secure spool position locking |

| Throttle Insert | Available in channel P |

| Compatible Fluids | HL, HLP, HLPD, HVLP, HVLPD, HETG, HEES, HEPG, HFDU, HFDR |

| Seals | FKM for compatibility and longevity |

| Versions | 3-way or 4-way |

| Mounting | Subplate with NFPA T.. R D Size CETOP D or ISO standards |

| Mechanical Efficiency | High, for start-stop functionality |

Key Takeaways

- 4WMM6 valves provide precise manual control over fluid flow, making them essential for various hydraulic systems.

- Regular maintenance, including inspections and cleaning, ensures the longevity and optimal performance of 4WMM6 valves.

- These valves are versatile and cost-effective, suitable for multiple industries, reducing the need for various valve types.

Functionality of 4WMM6 Valves

Basic Operation Principles

4WMM6 valves operate through a straightforward yet effective mechanism. These valves allow operators to control fluid direction manually, making them essential in various hydraulic systems. When an operator moves the hand lever, it directly actuates the control spool. This action changes the flow path of the fluid, directing it to the desired outlet.

Here’s a quick overview of how these valves function:

| Feature | Description |

|---|---|

| Type | High-performance directional control valve |

| Operation | Manual operation with direct actuation |

| Control Spool | Type H, designed for effective fluid flow management |

| Standby Mode | PTAB is open, allowing fluid flow when not actively controlled |

| Safety Feature | Spring centering for reliable return to neutral position |

| Application | Integrated into hydraulic systems for precision and safety |

This manual operation ensures that operators have full control over the fluid flow, which is crucial in applications requiring precision. The ability to return to a neutral position automatically enhances safety, preventing unintended fluid movement.

Key Components

Understanding the key components of 4WMM6 valves helps clarify their functionality. Each part plays a vital role in ensuring the valve operates smoothly and efficiently. Here’s a breakdown of the essential components:

| Component | Role in Operation |

|---|---|

| Housing | Encloses and supports the internal components of the valve |

| Control Spool | Directs the flow of fluid based on its position |

| Type of Actuation | Mechanism (hand lever) used to operate the control spool |

| Return Springs | Return the control spool to its neutral position when not actuated |

The housing provides structural integrity, while the control spool is the heart of the valve, managing fluid flow. The hand lever allows for manual operation, giving operators the flexibility they need. Return springs ensure that the spool returns to its original position, maintaining system stability.

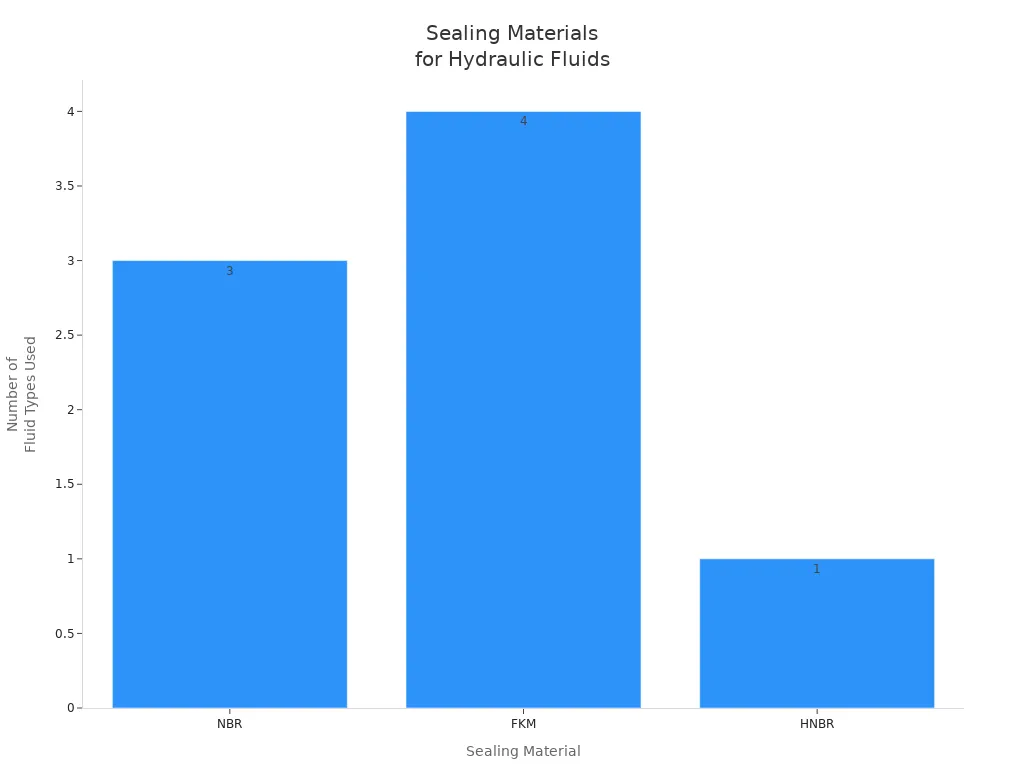

In addition to these components, the materials used in constructing 4WMM6 valves are crucial for their durability and performance. Common materials include NBR and FKM seals, which are compatible with various hydraulic fluids. This compatibility ensures that the valves can withstand different operating conditions without compromising their functionality.

Applications of 4WMM6 Valves

4WMM6 valves find their place in several industries, showcasing their versatility and effectiveness.

Industrial Uses

In industrial settings, these valves play a vital role in controlling fluid flow. They help manage hydraulic systems, ensuring machines operate smoothly. Operators can easily adjust the flow direction, which is crucial for tasks like lifting, pressing, or moving materials. The manual operation allows for quick adjustments, making them ideal for dynamic environments.

Agricultural Applications

Farmers rely on 4WMM6 valves for hydraulic control in agricultural machinery. These valves manage the flow direction of hydraulic oil, which is essential for operating hydraulic actuators like cylinders and motors. Here are some key points about their use in agriculture:

- Used in hydraulic systems for agricultural machinery

- Controls movement direction of hydraulic actuators

- Suitable for medium and high-pressure hydraulic systems

This functionality enhances the efficiency of equipment such as tractors and harvesters, allowing for precise control during operations.

Automotive Industry

In the automotive sector, 4WMM6 valves are crucial for hydraulic systems. They help control the flow and direction of hydraulic fluid in various applications. Here’s how they contribute:

- The Rexroth 4WMM6 series serves as a hydraulic manual actuation directional valve.

- These valves are relevant to hydraulic systems used in automotive manufacturing.

- They play a crucial role in controlling the flow and direction of hydraulic fluid in vehicle hydraulic systems.

By providing reliable control, these valves ensure that vehicles operate safely and efficiently.

Advantages of 4WMM6 Valves

Reliability and Durability

4WMM6 valves stand out for their reliability and durability, making them a preferred choice in various industrial applications. These valves are designed to withstand demanding conditions, ensuring consistent performance over time. Here are some key features that contribute to their reliability:

- High-performance design: The 4WMM6 series operates effectively under maximum pressures of up to 350 bar. This capability allows them to handle significant hydraulic loads without failure.

- Robust construction: The slide valve structure enables effective switching of the oil circuit, which is essential for directing hydraulic actuators like cylinders and motors.

- Long-term use: These valves are built to last, with materials that resist wear and tear, ensuring they perform reliably even in harsh environments.

The combination of these features makes 4WMM6 valves a dependable choice for industries that require consistent fluid control.

Cost-Effectiveness

Investing in 4WMM6 valves proves to be cost-effective for businesses. Their durability means fewer replacements and repairs, which translates to lower operational costs. Here’s how they save money:

- Reduced maintenance needs: The reliable design minimizes the frequency of maintenance checks, allowing operators to focus on other critical tasks.

- Versatile applications: These valves can be used across various industries, reducing the need for multiple valve types. This versatility simplifies inventory management and lowers costs.

- Energy efficiency: By providing precise control over fluid flow, 4WMM6 valves help optimize system performance, leading to energy savings.

Overall, the long-term savings associated with 4WMM6 valves make them a smart investment for any fluid control system.

Ease of Use and Maintenance

One of the standout features of 4WMM6 valves is their ease of use and maintenance. Operators appreciate how straightforward these valves are to work with. Here are some aspects that enhance user-friendliness:

- Compact design: The compact structure allows for easy installation, even in tight spaces. This design also enhances accessibility during maintenance.

- Industry-standard compatibility: These valves align with common industry dimensions, simplifying integration into existing systems.

- Quick-release connectors: Self-sealing quick-release coupling connectors ensure secure and leak-free connections, making maintenance tasks quicker and easier.

Additionally, the manual actuation through a hand lever improves user interaction, allowing for immediate adjustments as needed. With multiple ports available, operators can create flexible hydraulic connections, further enhancing the valve’s usability.

Maintenance Tips for 4WMM6 Valves

Maintaining 4WMM6 valves is essential for ensuring their longevity and optimal performance. Here are some practical tips to keep these valves in top shape.

Regular Inspection

Inspecting your valves regularly helps catch potential issues early. Here’s what to look for:

- Check for leaks: Look around the valve body and connections for any signs of fluid leakage.

- Monitor performance: Ensure the valve operates smoothly when actuated. Any unusual resistance may indicate a problem.

- Inspect seals: Examine the seals for wear or damage. Replacing worn seals can prevent leaks and maintain efficiency.

Cleaning Procedures

Keeping the valves clean is crucial for their operation. Follow these steps for effective cleaning:

- Disconnect the valve: Always ensure the system is depressurized before starting.

- Use a soft cloth: Wipe down the exterior to remove dirt and debris.

- Flush the system: If necessary, flush the hydraulic system with a compatible cleaning fluid to remove contaminants.

Tip: Regular cleaning can prevent buildup that may affect valve performance.

Troubleshooting Common Issues

Sometimes, issues arise despite regular maintenance. Here are some common problems and solutions:

- Valve not actuating: Check the manual actuation mechanism for obstructions or damage.

- Fluid flow issues: Inspect for blockages in the ports or hoses.

- Unusual noises: Listen for any grinding or rattling sounds, which may indicate internal wear.

By following these maintenance tips, operators can ensure that their 4WMM6 valves function effectively and reliably for years to come.

4WMM6 valves play a vital role across multiple industries. Their reliability, ease of use, and cost-effectiveness make them a top choice for fluid control.