Hydraulic plow valves significantly enhance plowing operations. They improve efficiency by reducing variations in plowing depth, which is crucial for achieving optimal performance. Over three decades, researchers have noted that electro-hydraulic control systems boost tractor tractive efficiency, making them a preferred choice in modern agricultural practices.

Key Takeaways

- Hydraulic plow valves enhance efficiency by allowing precise control over plow depth and angle, leading to consistent results and reduced errors.

- These valves provide superior control, enabling operators to make real-time adjustments for optimal performance in changing conditions.

- Durability is a key feature of hydraulic plow valves, built with high-strength materials to withstand harsh environments and heavy usage.

Overview of Hydraulic Plow Valves

Definition and Function

Hydraulic plow valves serve as critical components in modern plowing systems. These valves control the flow of hydraulic fluid, enabling operators to manage the movement of plow blades effectively. By regulating the hydraulic pressure, these valves allow for precise adjustments in plowing depth and angle.

The primary function of hydraulic plow valves is to facilitate smooth and efficient operation. When an operator engages the hydraulic system, the valve directs fluid to the appropriate cylinder, which then moves the plow. This process ensures that the plow maintains consistent contact with the ground, enhancing overall performance.

Hydraulic plow valves offer several advantages over traditional mechanical systems. They provide quicker response times, allowing for immediate adjustments during operation. This responsiveness is essential in dynamic environments, such as agricultural fields or construction sites, where conditions can change rapidly.

Additionally, hydraulic plow valves contribute to operator comfort. They reduce the physical effort required to control the plow, allowing operators to focus on other critical tasks. This ease of use makes hydraulic systems increasingly popular among professionals in various industries.

Key Benefits of Hydraulic Plow Valves

Enhanced Efficiency

Hydraulic plow valves significantly enhance operational efficiency in various plowing tasks. They allow for precise control over plow depth and angle, which leads to more consistent results. Studies demonstrate that hydraulic systems outperform traditional methods. For instance, one study on tractor draught control systems revealed superior performance at speeds of 2 miles per hour compared to depth wheel control. The findings indicated that errors in depth increased at higher speeds due to ground undulation constraints.

| Study | Findings |

|---|---|

| Field performance of tractor draught control systems | Superior performance at 2 mile/h compared to depth wheel control; errors in depth increased at higher speeds due to ground undulation constraints. |

Another practical effort to equip tractors with fuzzy depth and draft control systems showed a 20% increase in tractive efficiency and a 73% boost in overall energy efficiency. This study also noted a reduction in plowing depth error by 53%, driving wheel slip by 34%, and fuel consumption by 34%. Such improvements underscore the efficiency gains hydraulic plow valves offer.

| Study | Findings |

|---|---|

| A practical effort to equip tractor-implement with fuzzy depth and draft control system | Increment in tractive efficiency (20%) and overall energy efficiency (73%); reduction in plowing depth error (53%), driving wheel slip (34%), and fuel consumption (34%). |

Superior Control

Hydraulic plow valves provide operators with superior control over plowing operations. The ability to make real-time adjustments enhances the overall effectiveness of the plowing process. Operators can quickly respond to changing conditions, ensuring optimal performance. This level of control is particularly beneficial in environments where terrain varies significantly.

The responsiveness of hydraulic systems allows for smoother transitions and adjustments, which is crucial when navigating uneven ground or obstacles. Operators can maintain consistent plowing depth, leading to better crop yields and reduced soil compaction.

Increased Durability

Durability is a hallmark of hydraulic plow valves. These components are engineered to withstand harsh conditions and heavy usage. High-strength steel alloys are commonly used in the frame, enabling them to endure forces, vibrations, and environmental stresses.

- High-strength steel alloys are used in the frame to withstand forces, vibrations, and environmental stresses.

- Reinforced construction techniques enhance the frame’s durability under demanding conditions.

- Ballast plow blades are made from high-strength steel alloys and utilize advanced welding techniques for strength.

- Protective coatings on blades resist corrosion and abrasion.

Additionally, heavy-duty materials with high yield strength steel are utilized throughout hydraulic components, including flanges, to increase durability. This robust construction ensures that hydraulic plow valves can operate effectively over extended periods, reducing the need for frequent replacements.

Versatility in Applications

Hydraulic plow valves exhibit remarkable versatility, making them suitable for various applications beyond traditional plowing. They can be integrated into multiple types of machinery, enhancing their functionality. Some specific tasks and machinery that benefit from hydraulic plow valves include:

- Grapples

- Augers

- Snowplow tilt

- Snow blowers

- Brooms

- 4-in-1 buckets

- Tree pullers/shears

- Pallet forks

This versatility allows operators to adapt their equipment for different tasks, maximizing the utility of their machinery. Whether in agriculture, construction, or snow removal, hydraulic plow valves prove invaluable across diverse sectors.

Comparison of Hydraulic Plow Valves with Other Valves

Mechanical Valves vs. Hydraulic Valves

Mechanical valves have long been a staple in various machinery applications. However, they often fall short when compared to hydraulic plow valves. Mechanical valves rely on physical components to control fluid flow, which can lead to inefficiencies. Friction and deformation in mechanical systems can result in less accurate control over plowing operations. In contrast, hydraulic plow valves utilize fluid dynamics to achieve superior precision and responsiveness.

The advantages of hydraulic plow valves become evident in their operational efficiency. They provide smoother transitions and adjustments, allowing operators to maintain consistent plowing depth. This capability is particularly beneficial in challenging terrains where mechanical valves may struggle.

Manual Valves vs. Hydraulic Valves

Manual valves require operators to make adjustments by hand, which can be labor-intensive and time-consuming. This method often leads to higher user workload and increased fatigue. In contrast, hydraulic plow valves automate many of these adjustments, significantly reducing the physical effort required from operators.

The following table highlights the differences between manual valves and hydraulic plow valves in terms of operational efficiency and user workload:

| Feature | Manual Valves | Hydraulic Plow Valves |

|---|---|---|

| Operational Efficiency | Less accurate due to friction and deformation | Improved accuracy and stability |

| User Workload | Higher due to manual adjustments | Lower due to automated adjustments |

| Ease of Operation | More complex and labor-intensive | Easier and more comfortable to operate |

The table illustrates that hydraulic plow valves not only enhance operational efficiency but also provide a more user-friendly experience. Operators can focus on other critical tasks, knowing that the hydraulic system will manage plowing adjustments effectively.

Real-World Applications of Hydraulic Plow Valves

Agriculture

Hydraulic plow valves play a vital role in agricultural machinery. They maintain a cylinder in a fixed position, which is essential for tasks like crop cutting and plowing. These valves allow the cylinder rod to move freely, enabling implements to adjust to varying ground contours. This functionality is crucial for both smaller implements attached directly to tractors and larger towed implements that utilize their own hydraulic systems.

Construction

In construction, hydraulic plow valves enhance the efficiency of earthmoving and grading equipment. They integrate seamlessly with various systems, improving control and precision. The following table outlines common integration methods:

| Integration Method | Description |

|---|---|

| Ditch Assist System | Enhances grade control for earthmoving applications by integrating with factory-installed hydraulic valves. |

| Portable Valve | Allows easy switching between tractors or implements, facilitating quick changes in equipment. |

| RTK GPS Control | Provides automated hydraulic control for precise field leveling and drainage results. |

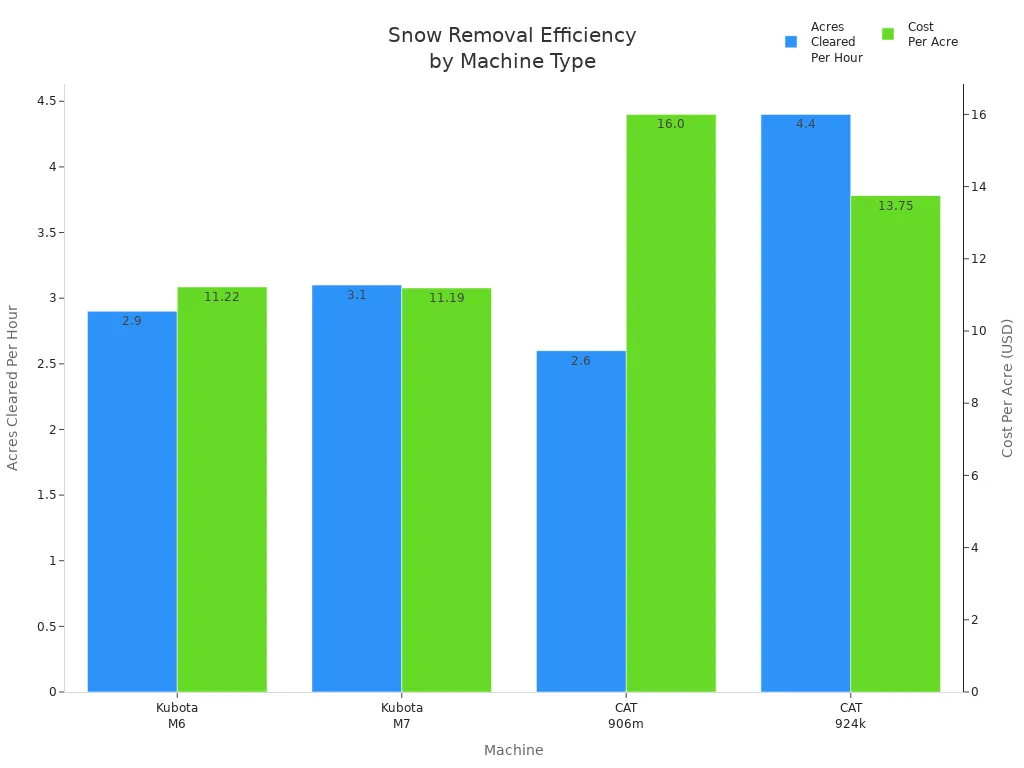

Snow Removal

Hydraulic plow valves are essential for effective snow removal operations, especially during winter. These components ensure that snowplows operate reliably under harsh conditions. High-quality hydraulic valves withstand freezing temperatures, enhancing the overall performance of snow removal equipment. Operators can control the plow’s blade position—raising, lowering, or angling—using hydraulic valves.

- The plow motor and pump provide hydraulic power to the cylinder.

- Operators benefit from improved efficiency, as demonstrated by the following statistics:

| Machine | Average Acres Cleared Per Hour | Total Cost Per Acre of Snow Clearing (Cash Price) |

|---|---|---|

| Kubota M6 | 2.90 | $11.22 |

| Kubota M7 | 3.10 | $11.19 |

| CAT 906m | 2.60 | $16.00 |

| CAT 924k | 4.40 | $13.75 |

These applications highlight the versatility and importance of hydraulic plow valves across various industries.

Hydraulic plow valves offer numerous advantages, including enhanced efficiency, superior control, increased durability, and versatility across applications. These benefits make them an essential choice for modern plowing operations. Consider integrating hydraulic plow valves into your equipment to optimize performance and achieve better results.