The Z2DS6 Series Pilot Controlled Modular Check Valves offers a remarkable upgrade for those facing maintenance challenges. This innovative solution enhances modular design, which leads to significant reductions in downtime. Manufacturers can now enjoy increased efficiency and reliability while minimizing disruptions. Embracing this technology can transform operational capabilities.

Key Takeaways

- The Z2DS6 Series valves reduce maintenance time and costs with their modular design, allowing easy access to components.

- Upgrading to the Z2DS6 Series can lead to significant improvements in operational efficiency and reliability across various industries.

- Investing in the Z2DS6 Series valves can minimize downtime, resulting in increased productivity and long-term savings.

Overview of Z2DS6 Series Pilot Controlled Modular Check Valves

The Z2DS6 Series Pilot Controlled Modular Check Valves represent a significant advancement in hydraulic technology. These valves are designed to enhance operational efficiency and reliability in various applications. With a robust construction and innovative features, they stand out in the market.

Key technical specifications include:

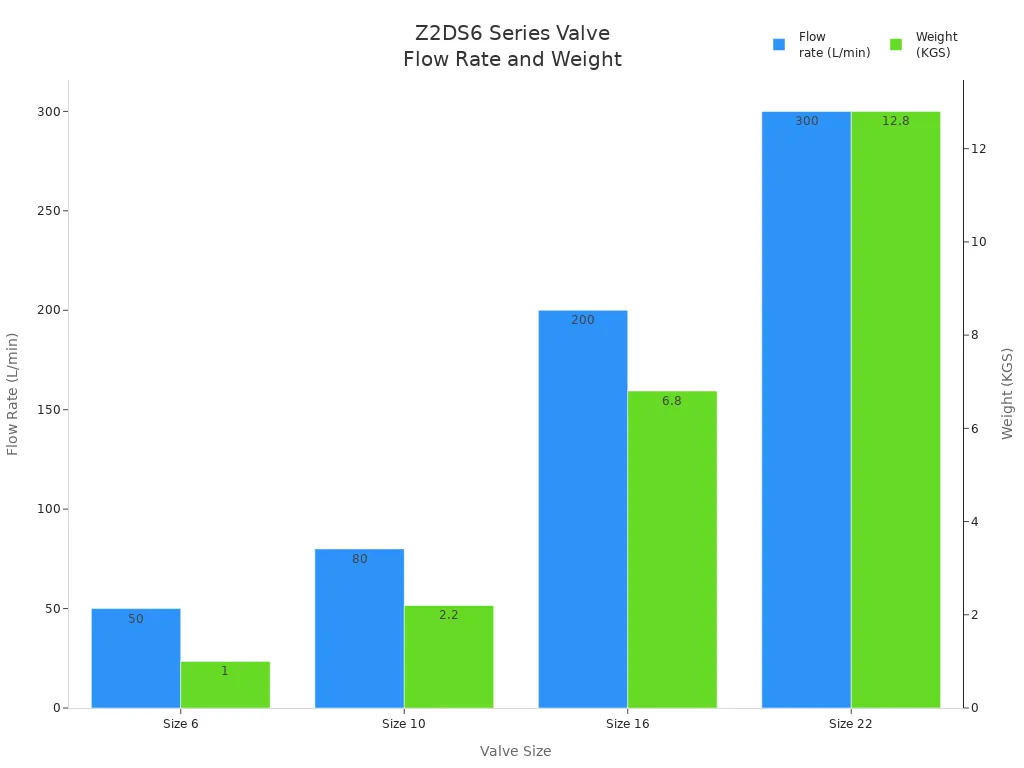

| Specification | Size 6 |

|---|---|

| Operating pressure (MPa) | 31.5 |

| Flow rate (L/min) | 50 |

| Fluid temperature range (℃) | -30~80 |

| Weight (KGS) | 1 |

| Valve body (Material) Surface treatment | casting phosphating surface |

| Oil cleanliness | NAS1638 class 9 and ISO4406 class 20/18/15 |

These valves operate effectively under high pressure, ensuring that systems run smoothly. The Z2DS6 SERIES PILOT CONTROLLED MODULAR CHECK VALVES can handle a wide temperature range, making them suitable for diverse environments. Their lightweight design facilitates easy installation and maintenance, further reducing downtime.

Modular Design Benefits of Z2DS6 Series

The modular design of the Z2DS6 SERIES PILOT CONTROLLED MODULAR CHECK VALVES brings numerous advantages that can significantly enhance operational efficiency. This innovative approach allows for easy customization and adaptability, making it a game-changer in the hydraulic industry. Here are some key benefits:

- Simplified Maintenance: The modular design enables quick access to individual components. Technicians can replace or repair parts without needing to dismantle the entire system. This feature drastically reduces maintenance time and costs.

- Enhanced Flexibility: Users can easily configure the Z2DS6 SERIES PILOT CONTROLLED MODULAR CHECK VALVES to meet specific application requirements. This flexibility allows for seamless integration into various systems, accommodating different flow rates and pressures.

- Improved Reliability: Each module undergoes rigorous testing to ensure high performance. The Z2DS6 SERIES PILOT CONTROLLED MODULAR CHECK VALVES maintain consistent quality, which translates to fewer breakdowns and increased uptime.

- Cost-Effective Solutions: By reducing downtime and maintenance costs, the modular design offers a more economical solution for manufacturers. Investing in these valves can lead to long-term savings and improved productivity.

Tip: When considering upgrades, think about how the modular design can streamline your operations. The Z2DS6 SERIES PILOT CONTROLLED MODULAR CHECK VALVES could be the key to unlocking greater efficiency in your processes.

Real-World Case Studies of Z2DS6 Series Impact

The Z2DS6 SERIES PILOT CONTROLLED MODULAR CHECK VALVES have made a significant impact across various industries. Here are some real-world case studies that showcase their effectiveness in solving maintenance issues and enhancing operational efficiency.

Case Study 1: Automotive Manufacturing

In an automotive manufacturing plant, the introduction of the Z2DS6 SERIES PILOT CONTROLLED MODULAR CHECK VALVES led to remarkable improvements. The plant faced frequent downtime due to valve failures. After switching to the Z2DS6 series, the maintenance team reported a 50% reduction in downtime. The modular design allowed technicians to replace faulty components quickly, minimizing disruptions in production. This change not only boosted productivity but also improved the overall reliability of the hydraulic systems.

Case Study 2: Construction Equipment

A construction equipment company struggled with hydraulic system failures that delayed project timelines. They implemented the Z2DS6 SERIES PILOT CONTROLLED MODULAR CHECK VALVES in their machinery. The results were impressive. The company experienced a 30% increase in equipment uptime. The valves’ ability to handle high pressures and diverse temperatures made them ideal for the demanding construction environment. Operators appreciated the enhanced performance, which translated into faster project completions and satisfied clients.

Case Study 3: Food Processing Industry

In the food processing sector, hygiene and reliability are paramount. A leading food manufacturer adopted the Z2DS6 SERIES PILOT CONTROLLED MODULAR CHECK VALVES to improve their hydraulic systems. The valves’ robust construction and easy maintenance features allowed the company to maintain strict hygiene standards while ensuring consistent operation. As a result, they achieved a 20% increase in production efficiency. The modular design facilitated quick cleaning and maintenance, aligning perfectly with the industry’s requirements.

Tip: These case studies illustrate the transformative power of the Z2DS6 SERIES PILOT CONTROLLED MODULAR CHECK VALVES. Companies across various sectors have experienced significant benefits, proving that investing in quality hydraulic solutions pays off.

The Z2DS6 SERIES PILOT CONTROLLED MODULAR CHECK VALVES not only address maintenance challenges but also enhance overall operational capabilities. Their real-world applications demonstrate their versatility and effectiveness in improving productivity and reliability.

Comparison with Previous Models of Z2DS6 Series

The Z2DS6 Series Pilot Controlled Modular Check Valves represent a significant leap forward compared to earlier models. Manufacturers can expect enhanced performance and reliability. Here are some key differences that set the Z2DS6 series apart:

- Improved Efficiency: The Z2DS6 series operates at a higher flow rate of 50 L/min, allowing systems to run more smoothly. Previous models struggled with lower flow rates, which often led to bottlenecks in production.

- Higher Operating Pressure: With an operating pressure of 31.5 MPa, the Z2DS6 series can handle more demanding applications. Earlier models had lower pressure ratings, limiting their use in high-stress environments.

- Modular Design: The modular design of the Z2DS6 series simplifies maintenance. Technicians can replace individual components quickly, reducing downtime. Previous models required more extensive disassembly, leading to longer maintenance periods.

- Versatile Temperature Range: The Z2DS6 series operates effectively in a temperature range of -30°C to 80°C. This versatility allows it to adapt to various environments, unlike older models that had narrower operational limits.

Tip: Upgrading to the Z2DS6 series can lead to significant improvements in efficiency and reliability. Embracing this technology can transform your operations.

The advancements in the Z2DS6 series make it a compelling choice for manufacturers looking to enhance their hydraulic systems.

The Z2DS6 Series stands as a beacon of innovation in hydraulic technology. It effectively tackles maintenance challenges, empowering manufacturers to enhance efficiency. With reduced downtime, companies can achieve greater productivity. Investing in the Z2DS6 Series transforms operations, paving the way for success and reliability in the manufacturing landscape.