Hanshang‘s top 10 DIRECTIONAL VALVES are the definitive choice for industrial applications in 2025. These hydraulic components offer advanced features. They deliver proven reliability essential for modern operational demands. Their design and technology perfectly align with automation, precision, and efficiency.

Key Takeaways

- Hanshang’s valves are good for 2025 because they have new features. They work well with modern machines.

- These valves are strong and last a long time. They meet high quality rules.

- Hanshang offers many types of valves. They fit different needs in factories.

Why Hanshang’s DIRECTIONAL VALVES Lead in 2025

Advanced Design for Modern Industrial Demands

Hanshang’s design philosophy centers on future industrial needs. Their advanced designs meet the demands of automation, precision, and efficiency. The company utilizes over 100 major manufacturing equipment pieces. These include CNC digital lathes, machining centers, and high-precision grinding machines. This advanced machinery ensures the production of components with exceptional accuracy. Hanshang’s R&D efforts continuously push boundaries. They create innovative solutions for complex hydraulic challenges. This commitment to innovation positions their DIRECTIONAL VALVES at the forefront of the industry.

Unmatched Reliability and Durability

Hanshang’s commitment to quality ensures unmatched reliability and durability. The company employs precision manufacturing and rigorous quality assurance. They hold ISO9001:2008 and CE certifications. These certifications confirm their adherence to international quality standards. Hanshang uses innovative materials and surface treatments. For example, the HVC6 series features castings with phosphating surface treatment. This treatment enhances corrosion resistance and extends valve life. High-precision honing machines contribute to the robust construction of each valve. This meticulous approach guarantees long-term performance in demanding environments.

Seamless Integration with Automation Systems

Hanshang’s DIRECTIONAL VALVES integrate seamlessly into modern automation systems. Their design considers the evolving needs of automated processes. Solenoid-operated valves, for instance, offer precise electronic control. This allows for rapid and accurate responses within automated sequences. The company’s products support high oil cleanliness standards. They meet NAS1638 Grade 9 and ISO4406 20/18/15 levels. This ensures optimal performance and longevity when paired with sensitive automation components. Hanshang’s valves provide the reliability and precision essential for efficient automated operations.

Key Types of Hanshang’s Top 10 DIRECTIONAL VALVES for 2025

Hanshang offers a diverse range of DIRECTIONAL VALVES. These valves meet the varied needs of modern industrial operations. Each type provides specific advantages for different applications.

Spool Valves for Precise Flow Control

Spool valves precisely control fluid flow. They use a cylindrical spool that slides within a bore. This movement directs hydraulic fluid to different ports. Industries widely use them for their ability to manage complex hydraulic circuits. Hanshang’s spool valves feature tight tolerances. This ensures smooth operation and accurate fluid direction.

Poppet Valves for Superior Leakage Prevention

Poppet valves excel at preventing leakage. A poppet element seals directly against a valve seat. This design creates a very tight shut-off. They are ideal for applications requiring zero or minimal internal leakage. Hanshang manufactures poppet valves with high-quality materials. This guarantees superior sealing performance and long service life.

Solenoid-Operated Valves for Automated Systems

Solenoid-operated valves are crucial for automated systems. An electrical signal activates a solenoid. The solenoid then moves the valve’s internal components. This allows for remote control and rapid response times. These valves integrate easily with programmable logic controllers (PLCs). Hanshang’s solenoid valves provide reliable and precise control for automated industrial processes.

Pilot-Operated Valves for High-Pressure Applications

Pilot-operated valves handle high-pressure applications effectively. A small pilot pressure controls the main valve’s operation. This design allows a small control signal to manage large fluid flows and high pressures. Heavy machinery and robust hydraulic systems often utilize them. Hanshang engineers these valves for exceptional durability. They perform consistently under demanding conditions.

Manual and Mechanically-Operated Valves for Direct Control

Manual and mechanically-operated valves offer direct control. Manual valves use levers or knobs for human operation. Mechanically-operated valves respond to physical contact, like cams or rollers. These valves provide simple and reliable control. They are suitable for applications where direct intervention is necessary. Hanshang designs these valves for straightforward functionality and robust performance.

Hanshang’s Technological Edge in DIRECTIONAL VALVES

Precision Manufacturing and Quality Assurance

Hanshang invests heavily in advanced manufacturing equipment. CNC digital lathes, machining centers, and high-precision grinding machines ensure exceptional component accuracy. High-precision honing machines further refine internal surfaces. This meticulous process guarantees the precise fit and function of every valve. Hanshang also implements an ERP administration model. This system streamlines operations. It ensures consistent quality control from design to production.

Innovative Materials and Surface Treatments

Hanshang selects innovative materials for its hydraulic components. They also apply advanced surface treatments. The HVC6 series, for example, features castings with phosphating. This treatment significantly enhances corrosion resistance. It extends the valve’s operational life in harsh industrial environments. These material choices contribute to the overall durability and performance of Hanshang’s products.

Meeting Industry Standards and Certifications

Hanshang holds ISO9001:2008 and CE certifications. These confirm adherence to global quality benchmarks. Their products also meet strict oil cleanliness standards. These include NAS1638 Grade 9 and ISO4406 20/18/15. This commitment to standards ensures reliability and compatibility. It allows seamless integration into diverse hydraulic systems worldwide.

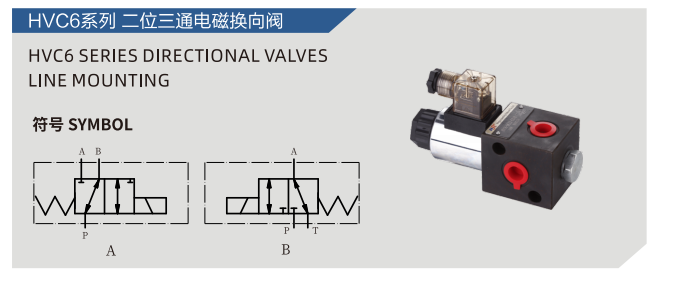

Specific Product Spotlight: HVC6 Series Directional Valves

The HVC6 Series DIRECTIONAL VALVES exemplify Hanshang’s engineering excellence. This two-position, three-way solenoid valve offers a maximum flow of 50 L/min. It handles a maximum working pressure of 25 Mpa. Its cast body receives phosphating surface treatment. This ensures durability. It also maintains the specified oil cleanliness standards. The HVC6 series provides reliable and precise control for various applications.

Hanshang engineers their top 10 directional control valves for the challenges and opportunities of 2025. Their blend of innovation, quality, and performance ensures optimal system efficiency and longevity. Choosing Hanshang means investing in future-proof hydraulic solutions. These solutions meet diverse industrial needs.

FAQ

Why are Hanshang directional control valves ideal for 2025?

Hanshang valves offer advanced features and proven reliability. They meet modern demands for automation, precision, and efficiency. This ensures future-proof hydraulic solutions.

Do Hanshang valves integrate with automated systems?

Yes, Hanshang’s solenoid-operated valves provide precise electronic control. They integrate seamlessly with PLCs. This supports rapid, accurate responses in automated industrial processes.

What quality standards do Hanshang directional control valves meet?

Hanshang valves hold ISO9001:2008 and CE certifications. They also meet NAS1638 Grade 9 and ISO4406 20/18/15 oil cleanliness standards.