A HYDRAULIC FLOW CONTROL VALVE serves as a crucial mechanical device. It precisely regulates the rate of fluid flow within a hydraulic system. This essential component directly controls actuator speed. It also significantly optimizes overall system performance. Engineers rely on this valve for accurate and efficient operational management in diverse applications.

Key Takeaways

- Hydraulic flow control valves manage fluid flow. They control how fast parts move in a machine.

- These valves help machines work smoothly. They make sure parts move at the right speed.

- Proper use of these valves saves energy. It also makes machines last longer.

Secret 1: The Core Mechanism of a HYDRAULIC FLOW CONTROL VALVE

The Principle of Flow Restriction

A HYDRAULIC FLOW CONTROL VALVE operates on the fundamental principle of flow restriction. It precisely regulates the volume of hydraulic fluid moving through a circuit. This regulation occurs by altering the size of the passage through which the fluid flows. When the passage narrows, it restricts the fluid’s path. This restriction creates a pressure differential across the valve. Consequently, it reduces the flow rate. This direct control over flow rate allows engineers to manage the speed of hydraulic actuators, such as cylinders and motors. The valve ensures consistent and predictable movement within the system. This precise management is crucial for applications requiring exact positioning or timing, preventing jerky movements and ensuring smooth operation.

Key Components for Flow Regulation

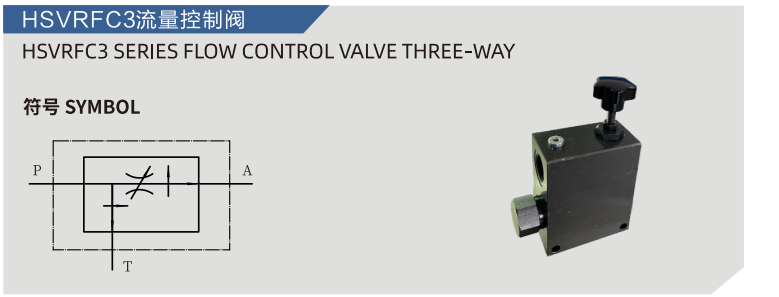

Several key components work together to achieve this precise flow regulation. The main element is often a spool or a needle. This component moves to change the effective area of the flow path, known as the orifice. This variable orifice is the heart of the flow control. An adjusting mechanism, such as a hand knob or a screw, connects to the spool or needle. Operators use this mechanism to manually or remotely adjust the orifice size. This adjustment directly impacts the amount of fluid passing through, allowing for fine-grained control. Some advanced HYDRAULIC FLOW CONTROL VALVES also incorporate a compensator. This compensator maintains a constant flow rate despite variations in system pressure, enhancing stability. Together, these parts allow for fine-tuning the fluid’s passage. This ensures optimal performance and efficiency in diverse hydraulic applications.

Secret 2: Types of HYDRAULIC FLOW CONTROL VALVES and Their Operations

Different types of HYDRAULIC FLOW CONTROL VALVES exist. Each type offers specific operational characteristics. Engineers select them based on application requirements. Understanding these differences is crucial for system design and performance.

Non-Compensated Flow Control Valves

Non-compensated valves are the simplest form. They regulate flow by a fixed or adjustable orifice. The flow rate through these valves directly depends on the pressure difference across them. If the load on the actuator changes, the pressure changes. This causes the flow rate to vary. Consequently, the actuator speed also changes. These valves are suitable for systems where precise speed control is not critical. They also work well in applications with constant loads.

Pressure-Compensated Flow Control Valves

Pressure-compensated valves maintain a constant flow rate. They do this even when system pressure changes. A compensator spool is key to their operation. This spool senses pressure differences. It then adjusts the effective orifice size. This adjustment counteracts pressure fluctuations. As a result, the flow rate remains stable. Actuator speed stays consistent regardless of load variations. These valves are vital for applications needing precise and stable motion control.

Temperature-Compensated Flow Control Valves

Temperature changes affect hydraulic fluid viscosity. Viscosity changes can alter flow rates through an orifice. Temperature-compensated valves address this issue. They incorporate special materials or mechanisms. These components adjust for thermal expansion or contraction. This ensures a stable flow rate. They maintain accuracy even when fluid temperature fluctuates. Such valves are important for high-precision systems operating in environments with varying temperatures.

Secret 3: The Role of HYDRAULIC FLOW CONTROL VALVE in System Performance

Controlling Actuator Speed

A HYDRAULIC FLOW CONTROL VALVE plays a critical role in managing actuator speed. It directly dictates the rate at which hydraulic fluid reaches a cylinder or motor. By adjusting the flow rate, operators precisely control the speed of movement. For example, a slower flow rate results in a slower extension of a hydraulic cylinder. Conversely, a higher flow rate makes the cylinder extend faster. This precise control is essential for applications requiring specific timing or delicate movements. It ensures machinery operates smoothly and predictably.

Ensuring Synchronized Movement

Many hydraulic systems feature multiple actuators. These actuators often need to move in perfect unison. A HYDRAULIC FLOW CONTROL VALVE helps achieve this synchronized movement. Engineers install individual flow control valves for each actuator. They then fine-tune each valve to deliver the exact required flow rate. This ensures all actuators move at the same speed or in a coordinated sequence. Such synchronization is vital in applications like lifting platforms or robotic arms. It prevents uneven loading and maintains operational stability.

Energy Efficiency Considerations

Proper flow control significantly impacts a hydraulic system’s energy efficiency. Uncontrolled flow can lead to wasted energy. For instance, excessive flow generates unnecessary heat and pressure drops. A well-adjusted flow control valve delivers only the necessary amount of fluid. This minimizes energy consumption. It also reduces heat generation. Efficient flow management extends the lifespan of hydraulic components. It also lowers operational costs. Therefore, optimizing flow control contributes to a more sustainable and economical system.

Secret 4: Installation and Adjustment of a HYDRAULIC FLOW CONTROL VALVE

Placement in the Hydraulic Circuit

Proper placement of a HYDRAULIC FLOW CONTROL VALVE is crucial for its effective operation. Engineers typically install these valves directly upstream of the actuator they control. This positioning allows the valve to precisely regulate the fluid volume entering the cylinder or motor. For instance, to control the speed of a hydraulic cylinder, technicians place the valve in the line feeding oil to that cylinder. This direct control ensures accurate speed management. Incorrect placement can lead to inefficient operation or even system instability. Consider the specific function the valve performs when determining its location within the hydraulic circuit.

Fine-Tuning for Optimal Performance

Fine-tuning a flow control valve ensures optimal system performance. This process involves a series of adjustments and observations. First, technicians make an initial setting based on system requirements. They then activate the hydraulic system and observe the actuator’s movement. If the speed is too fast or too slow, they adjust the valve’s setting incrementally. Small adjustments are key to achieving precision. Operators monitor the actuator’s response after each change. This iterative process continues until the actuator achieves the desired speed and smooth operation. Proper fine-tuning maximizes efficiency and prevents jerky movements, ensuring the system performs exactly as intended.

Secret 5: Common Issues and Troubleshooting a HYDRAULIC FLOW CONTROL VALVE

Symptoms of Malfunction

Operators often observe specific signs when a HYDRAULIC FLOW CONTROL VALVE malfunctions. An actuator might move erratically or at an incorrect speed. For instance, a cylinder could extend too slowly or too quickly, deviating from its set pace. System overheating can also indicate a problem, as restricted or improper flow generates excess heat. Furthermore, inconsistent performance, where the actuator speed varies despite constant load, points to a potential valve issue. A noticeable drop in system efficiency or increased noise levels during operation also suggests a malfunction. These symptoms collectively signal the need for inspection and potential adjustment or repair.

Basic Troubleshooting Steps

Troubleshooting a HYDRAULIC FLOW CONTROL VALVE involves a systematic approach. First, technicians should verify the valve’s current setting. An incorrect adjustment often causes performance issues. They then inspect the valve for external damage or leaks, which can compromise its function. Next, they check the hydraulic fluid for contamination. Dirty fluid can clog the valve’s internal passages, impeding proper flow. Technicians also confirm system pressure. Insufficient or excessive pressure can affect the valve’s ability to regulate flow accurately. If these steps do not resolve the issue, they might need to disassemble the valve. This allows for a thorough internal inspection for blockages, worn components, or damaged seals. Replacing faulty parts or cleaning internal passages often restores the valve to optimal operation.

Hydraulic flow control valves precisely regulate fluid flow. They directly control actuator speed and system performance. These valves are critical for achieving precise, efficient, and safe hydraulic operations. Understanding their function and operation ensures effective system management. This knowledge optimizes overall hydraulic system reliability.

FAQ

.png)

What is the primary function of a hydraulic flow control valve?

A hydraulic flow control valve regulates the rate of fluid flow. This directly controls actuator speed and optimizes overall system performance.

How does a pressure-compensated flow control valve differ from a non-compensated one?

Pressure-compensated valves maintain a constant flow rate despite pressure changes. Non-compensated valves’ flow rate varies with system pressure fluctuations.

Why is proper placement of a flow control valve important?

Proper placement ensures precise regulation of fluid volume. Install it upstream of the actuator for effective speed control and system stability.