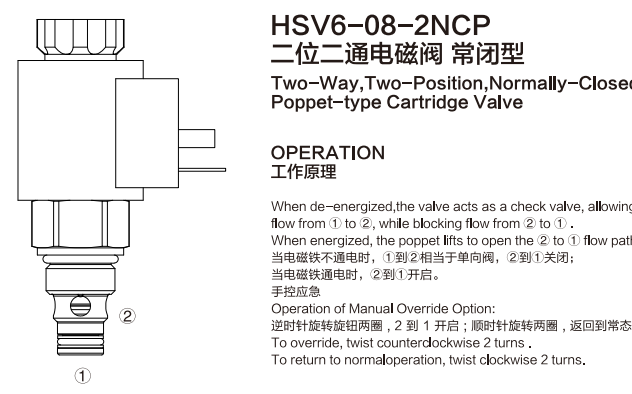

Quality standards for solenoid valves china ensure their performance and reliability. International, national (GB), and industry-specific certifications govern these products. For instance, hanshang produces high-quality Solenoid Valve products like the HSV6-08-2NCP, meeting global market demands for safety and function.

Key Takeaways

- Solenoid valves from China follow strict quality rules. These rules include global standards like ISO and CE, and China’s own GB standards.

- Makers of these valves use strong checks inside their factories. This helps make sure every valve works well and is safe.

- When you buy solenoid valves, pick makers who clearly follow these quality rules. This helps you get good and safe products.

International Quality Standards for Solenoid Valves from China

Manufacturers of solenoid valves from China often adhere to a range of international quality standards. These standards ensure products meet global benchmarks for safety, performance, and environmental responsibility. Compliance with these certifications demonstrates a commitment to quality and facilitates market access worldwide.

ISO 9001: Quality Management System Foundation

ISO 9001 establishes the fundamental requirements for a quality management system (QMS). This standard does not certify the product itself but rather the processes a company uses to design, develop, produce, install, and service its products. For solenoid valves, ISO 9001 certification indicates a manufacturer consistently provides products and services that meet customer and regulatory requirements. It also shows the company aims to enhance customer satisfaction through effective application of the system, including processes for improvement. Ningbo Hanshang Hydraulic Co., Ltd., for example, has obtained ISO9001:2008 certification, showcasing their dedication to robust quality management in their production of hydraulic valves and systems.

CE Marking: European Conformity and Directives

The CE marking signifies a product’s conformity with European Union (EU) health, safety, and environmental protection standards. Manufacturers attach the CE mark to products sold within the European Economic Area (EEA). For solenoid valves, this often involves compliance with directives such as the Low Voltage Directive (LVD), Electromagnetic Compatibility (EMC) Directive, and sometimes the Pressure Equipment Directive (PED). A CE mark on solenoid valves from China assures European buyers the product meets essential safety and performance criteria for their market.

RoHS Compliance: Restricting Hazardous Substances

RoHS (Restriction of Hazardous Substances) compliance addresses the use of specific hazardous materials in electrical and electronic products. This directive originated in the European Union but has become a global standard. It restricts the use of lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE). For solenoid valves, RoHS compliance ensures the components do not contain these harmful substances, contributing to environmental protection and safer product disposal. Manufacturers of solenoid valves china increasingly adopt RoHS to meet international environmental regulations.

UL/CSA Certifications: North American Safety Requirements

UL (Underwriters Laboratories) and CSA (Canadian Standards Association) certifications are crucial for products entering the North American market. These organizations develop safety standards and perform product testing and certification. UL and CSA marks indicate a product has undergone rigorous testing and meets specific safety requirements for electrical and mechanical components. For solenoid valves, these certifications confirm the valves operate safely under specified conditions, reducing risks of electrical shock, fire, or other hazards. Manufacturers seeking to export solenoid valves to the United States and Canada prioritize these certifications.

ATEX/IECEx: Standards for Hazardous Environments

ATEX (Atmosphères Explosibles) and IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres) are international standards for equipment intended for use in potentially explosive atmospheres. These certifications are vital for solenoid valves installed in industries like oil and gas, chemical processing, or mining, where flammable gases, vapors, mists, or dusts may be present. ATEX applies specifically to the EU, while IECEx provides a globally accepted standard. Both ensure the design and construction of solenoid valves prevent them from becoming an ignition source in hazardous locations, thereby enhancing safety in critical industrial applications.

National Standards and Manufacturer Quality Control for Solenoid Valves China

Overview of Chinese GB Standards

GB standards are China’s national standards. They ensure product quality and safety. These standards cover a wide range of products. They include industrial components like solenoid valves. Compliance with GB standards is crucial for products sold within China. They also serve as a baseline for export quality. These national regulations provide a framework. They guide manufacturers in producing reliable goods.

Specific GB Standards for Solenoid Valves

Specific GB standards apply directly to solenoid valves. These standards define performance requirements. They also detail testing methods. Safety requirements are an important part of these standards. Manufacturers must follow these rules for domestic sales. This ensures the quality of solenoid valves china. For example, standards cover electrical safety, hydraulic performance, and material specifications. Adherence to these specific guidelines guarantees product integrity.

Manufacturer Internal Quality Assurance Processes

Manufacturers implement strong internal quality control. This goes beyond external certifications. They begin with inspecting incoming materials. This ensures raw components meet specifications. They perform checks during the production process. This includes machining and assembly stages. Final product testing is also critical. This involves pressure tests, electrical performance checks, and leakage detection. Companies use advanced equipment. CNC machines, high-precision grinders, and honing machines ensure accuracy. ERP systems manage production processes efficiently. This comprehensive approach leads to continuous quality improvement.

Importance of Traceability and Documentation

Traceability is very important for quality control. It tracks components, production batches, and manufacturing dates. This helps manage product quality effectively. It aids in potential product recalls. It also assists with troubleshooting any issues. Comprehensive documentation supports this system. Test reports show product performance data. Material certificates confirm component quality. Assembly records detail production steps. Maintenance manuals provide operational guidance. These documents ensure long-term reliability. They build strong customer confidence in solenoid valves china.

- Solenoid valves from China meet high quality standards. International certifications like ISO, CE, RoHS, UL/CSA, ATEX/IECEx ensure this. National GB standards also play a role.

- Manufacturers implement strong internal quality controls. These processes support external certifications.

- Buyers should prioritize manufacturers. They must show clear compliance with these standards. This ensures reliable and safe products.

FAQ

What is the main purpose of ISO 9001 for solenoid valves?

ISO 9001 certifies a manufacturer’s quality management system. It ensures consistent product quality and customer satisfaction. It does not certify the product itself.